0

0

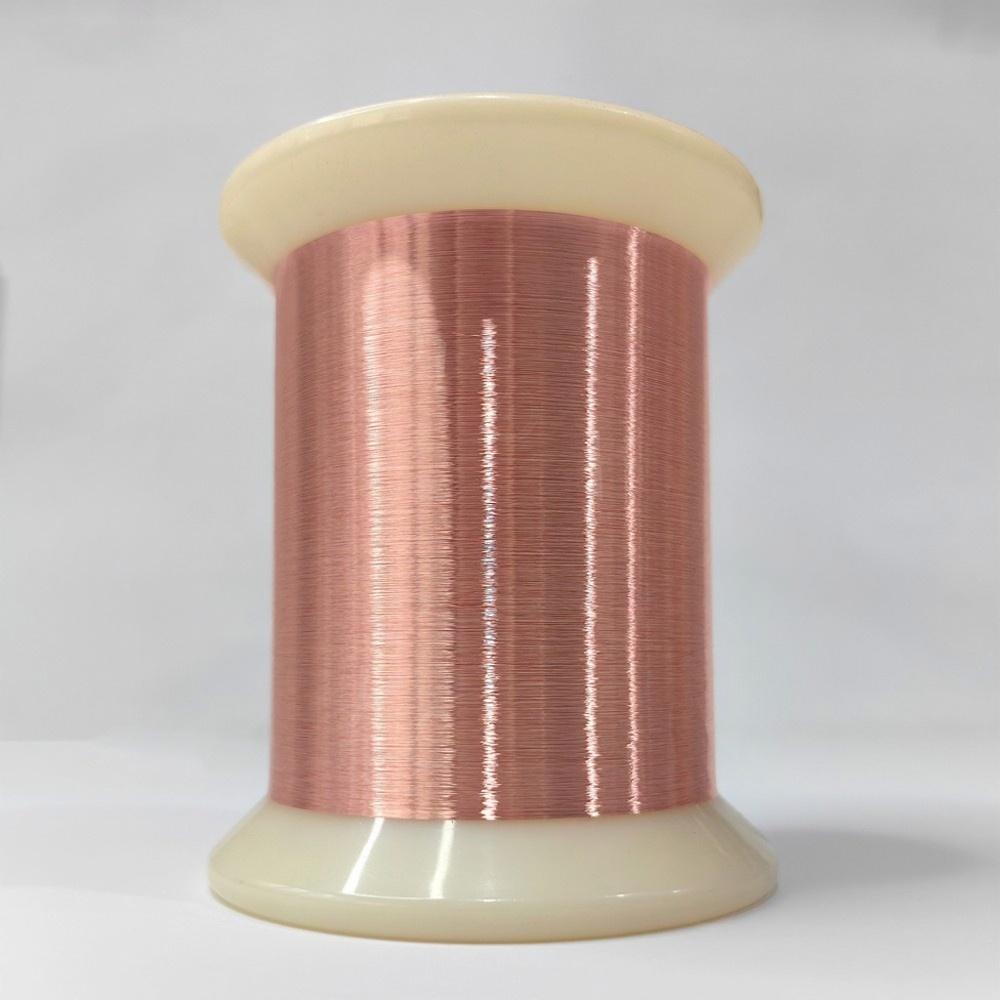

Products Description

CuNi6 is a copper-nickel alloy containing approximately 6% nickel. This alloy is widely used in the chemical industry because of its excellent corrosion resistance. CuNi6 maintains stable corrosion resistance in the face of a variety of chemical media, including acidic, alkaline and neutral solutions, making it very suitable for use in the manufacture of pipes, valves, pumps and heat exchangers in chemical processes. and other equipment. In addition, CuNi6 also has good processing properties and can be easily processed into complex part shapes, as well as excellent thermal conductivity, making it suitable for efficient heat exchange applications. Therefore, CuNi6 alloy is a valuable material in the chemical industry for building corrosion-resistant equipment, helping to improve the reliability, safety and service life of the equipment.

Specification

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more other size details, pls directly contact us.

Feature

Excellent corrosion resistance: There are various corrosive media in the chemical environment, including acidic, alkaline and salt solutions, which may cause corrosion to metal equipment. CuNi6 alloy has excellent corrosion resistance and can maintain stable performance in various corrosive media and extend the service life of equipment.

Good mechanical properties: CuNi6 alloy has good mechanical strength and toughness, allowing it to withstand high pressure and high temperature in chemical equipment. It also has good processing performance and can be made into parts of various complex shapes.

Anti-oxidation performance: In high temperature, high pressure and oxidizing environments, CuNi6 alloy shows good anti-oxidation performance, which can prevent surface oxidation and corrosion and maintain the surface finish and performance stability of the equipment.

Thermal conductivity: CuNi6 alloy has good thermal conductivity and can conduct heat quickly and evenly, allowing chemical equipment to control temperature more effectively and improve production efficiency.

Low-temperature stability: In low-temperature environments, CuNi6 alloy still maintains good mechanical properties and corrosion resistance, and is suitable for some chemical equipment that needs to operate under low-temperature conditions.

Application areas:

Chemical reactors: CuNi6 alloy is often used to manufacture chemical reactors. These reactors are used to carry out various chemical reactions, such as acid-base neutralization, oxidation-reduction, etc. Because CuNi6 alloy has excellent corrosion resistance and oxidation resistance, it can resist the corrosion and oxidation of equipment by acid and alkali solutions and oxidizing media generated during chemical reactions, ensuring the long-term stable operation of the reactor.

Storage tanks and containers: In the chemical production process, various chemicals and raw materials need to be stored and transported, which requires materials with excellent corrosion resistance to manufacture storage tanks and containers. Due to its good corrosion resistance and mechanical properties, CuNi6 alloy is often used to manufacture storage tanks and containers for storing acid and alkali solutions, brine, chemicals, etc.

Heat exchangers and coolers: In chemical production, heat exchange and temperature control are required, which requires the use of heat exchangers and coolers. Due to its good thermal conductivity and corrosion resistance, CuNi6 alloy is often used to manufacture heat exchangers and coolers to control the temperature in the chemical production process and improve production efficiency.

Pipes and valves: A large number of pipes and valves are required in chemical production to transport and control various chemicals and media. These pipes and valves need to have excellent corrosion resistance and mechanical properties. CuNi6 alloy is often used to manufacture pipes and valves to ensure safe operation and long-lasting stability in chemical production processes.

Chemical Instruments: Various instruments and equipment are needed in chemical production to monitor and control the production process. These instruments and equipment usually need to have corrosion resistance and stable performance. CuNi6 alloy is often used to manufacture chemical instruments, such as flow meters, pressure gauges, etc., to ensure accurate monitoring and control of the production process.

Summarize

CuNi6 alloy has excellent characteristic advantages in the chemical industry, including corrosion resistance, mechanical properties, oxidation resistance, thermal conductivity and low temperature stability. These excellent properties make CuNi6 alloy one of the important materials in chemical equipment manufacturing, providing reliable technical support for the development of the chemical industry.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China