0

0

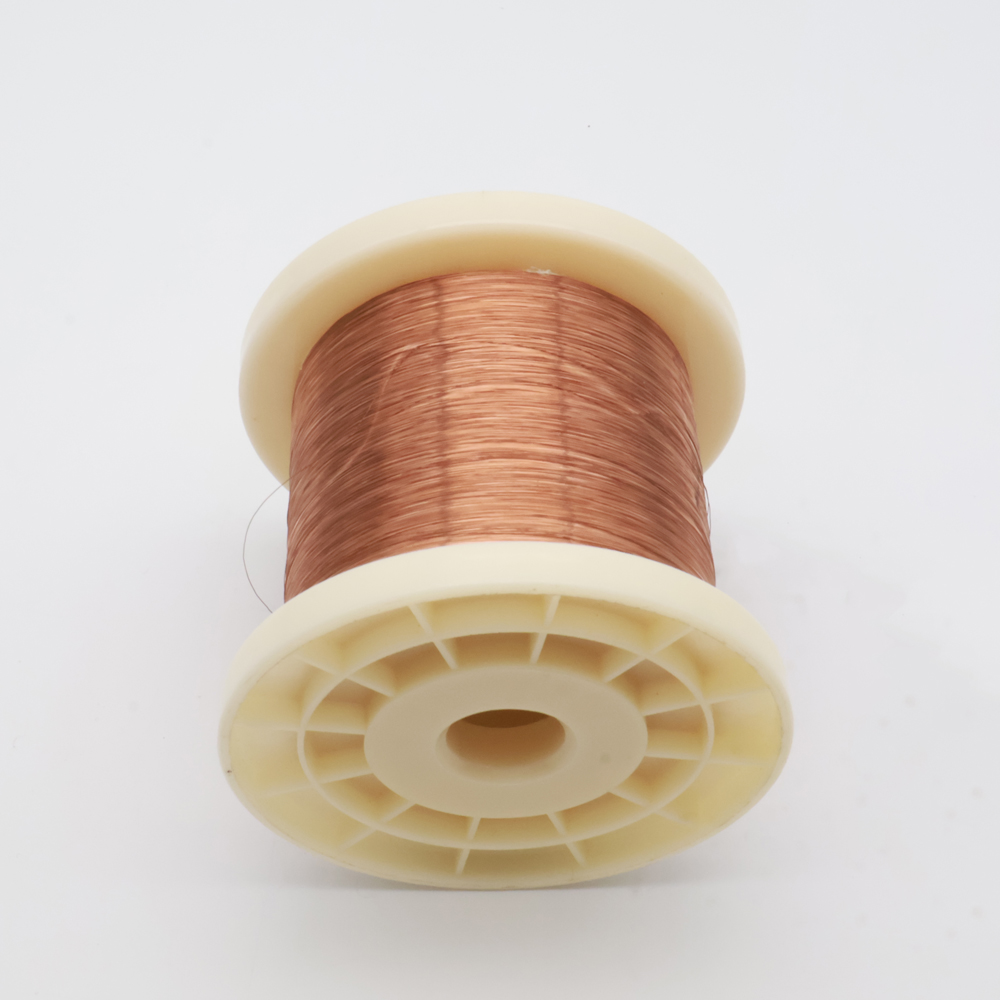

Products Description

Copper-nickel resistance wire is an important resistance alloy. Common models include CuNi10, CuNi14, CuNi19, CuNi23 and CuNi30, etc. These resistance wires have a unique set of properties that make them useful in a variety of applications.

CuNi10 resistance wire is known for its stable resistance characteristics and good electrical conductivity. It is commonly used in electrical engineering for circuit control and temperature measurement, as well as in the manufacture of heating elements in household appliances.

CuNi14 resistance wire has good corrosion resistance and thermal stability, and is suitable for long-term stable operation in harsh environments. It is often used in sensor manufacturing in industrial automation equipment, aerospace devices and medical equipment.

CuNi19 resistance wire has high mechanical strength and heat resistance, and is suitable for industrial applications in high temperature environments. It is often used in temperature measurement and control of high-temperature processes, as well as instrumentation manufacturing in the aerospace field.

CuNi23 resistance wire is an alloy with good thermal conductivity and is often used to manufacture thermocouples and temperature sensors to ensure precise control and stability of industrial processes.

In summary, copper-nickel resistance wires such as CuNi10, CuNi14, CuNi19, CuNi23 and CuNi30, with their respective characteristics and advantages, provide important support and support for the fields of electrical engineering, electronic equipment, industrial automation, aerospace and medical equipment. Value.

Specification

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more other size details, pls directly contact us.

introduce:

CuNi10 (white copper B10)

Nickel content: about 10%

Characteristics: Excellent seawater corrosion resistance, excellent cold and hot processing performance, and high tensile strength and yield strength.

Application: Widely used in shipbuilding, marine engineering, chemical industry, especially in seawater desalination, heat exchangers and some power plants.

CuNi14

Nickel content: about 14%

Characteristics: Compared with CuNi10, CuNi14 has a higher nickel content, which further improves its corrosion resistance, especially in more harsh chemical and marine environments.

CuNi19

Nickel content: about 19%

Characteristics: CuNi19 provides stronger corrosion resistance than CuNi10 and CuNi14, while maintaining good mechanical properties and processability.

Applications: Suitable for more extreme chemical processing and marine applications, and other environments requiring high corrosion resistance.

CuNi23

Nickel content: about 23%

Properties: CuNi23 is a high-nickel alloy with excellent corrosion resistance and excellent mechanical properties, especially in high temperature and high pressure applications.

Application: Commonly used in the manufacture of high-performance heat exchangers, subsea pipelines and chemical equipment.

Common characteristics:

Corrosion Resistance: These copper-nickel alloys all exhibit excellent corrosion resistance, especially in chemical and marine environments.

Processability: It has good cold and hot processing properties and can be processed into resistance wires of various shapes and sizes.

High strength: Compared to pure copper, copper-nickel alloys exhibit higher mechanical strength and hardness.

Thermal stability: No phase change occurs during hot and cold processing, ensuring the consistency of the mechanical properties and corrosion resistance of the alloy.

Application areas:

Marine engineering: ships, offshore platforms, seawater desalination equipment, etc.

Chemical industry: corrosion-resistant pipes, valves, pumps and heat exchangers, etc.

Precision instruments: thermocouples, resistors, and other resistive components that require high precision and stability.

Electric power industry: used as heating wire to manufacture heating cables, snow melting systems, etc.

By adjusting the ratio of nickel content and other alloying elements, the properties of copper-nickel resistance wire can be optimized to meet the requirements of specific applications, making it an indispensable material in many fields such as industry, marine, chemical and power generation.

Production Process

Raw material preparation: The raw materials for producing copper-nickel resistance wire are mainly high-purity copper and nickel. These raw materials need to be precisely proportioned and mixed to ensure that the final alloy has the desired characteristics and performance.

Smelting the alloy: Put the proportioned copper and nickel raw materials into the furnace, heat them to the melting point of the alloy, and make them completely melted and mixed thoroughly. During the smelting process, other alloying elements may need to be added to adjust the composition and properties of the alloy.

Wire drawing: The molten alloy is drawn through a metal mold or wire drawing machine into a wire of the required diameter. In this process, the drawing speed and temperature need to be controlled to ensure that the size and performance of the wire meet the requirements.

Annealing treatment: The drawn copper-nickel alloy wire is annealed to eliminate internal stress and improve the uniformity of grains. The control of annealing temperature and time is crucial to the performance and stability of the wire.

Surface treatment: Treat the surface of the copper-nickel resistance wire to remove surface oxides and other impurities and improve its conductivity and corrosion resistance.

Testing and quality inspection: Strict testing and quality inspection are conducted on the copper-nickel resistance wire produced, including testing of resistance value, diameter, surface quality, etc. Only wire materials that pass quality inspection can enter the downstream processing and application links.

Packaging and storage: Qualified copper-nickel resistance wires are packaged according to specified standards and stored under appropriate environmental conditions to ensure that they are not contaminated and damaged during transportation and use.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China