0

0

Products Description

Copper-nickel resistance wire is an important type of resistance alloy. Common models include CuNi30, CuNi34, CuNi40 and CuNi44. These resistance wires are widely used in various fields due to their unique properties.

CuNi30 resistance wire has excellent corrosion resistance and electrical properties, and is often used in the manufacturing of electronic components in harsh environments such as chemical equipment, marine engineering, and oil drilling. Its excellent corrosion resistance ensures long-term reliable operation of equipment in challenging environments.

CuNi34 resistance wire has good electrical conductivity and stable resistance characteristics, and is suitable for circuit connections and sensor manufacturing in precision instruments, automated control systems and electronic equipment. Its stability and reliability ensure the accuracy and long-term stability of the equipment.

CuNi40 resistance wire is a commonly used high-temperature alloy with good mechanical strength and heat resistance, and is suitable for temperature measurement and control of high-temperature processes. It is often used in furnace temperature monitoring, aerospace devices and heat treatment equipment to ensure process stability and product quality.

CuNi44 resistance wire is a special alloy with excellent magnetic and thermal conductivity properties. It is often used in the manufacture of temperature sensors and thermocouples in motors, transformers and power generation equipment. Its high-precision temperature measurement capabilities ensure safe operation and optimized performance of equipment.

In summary, copper-nickel resistance wires such as CuNi30, CuNi34, CuNi40 and CuNi44, with their respective characteristics and advantages, provide important support and application value for electronic equipment, industrial automation, energy fields, etc. in many fields.

Specification

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

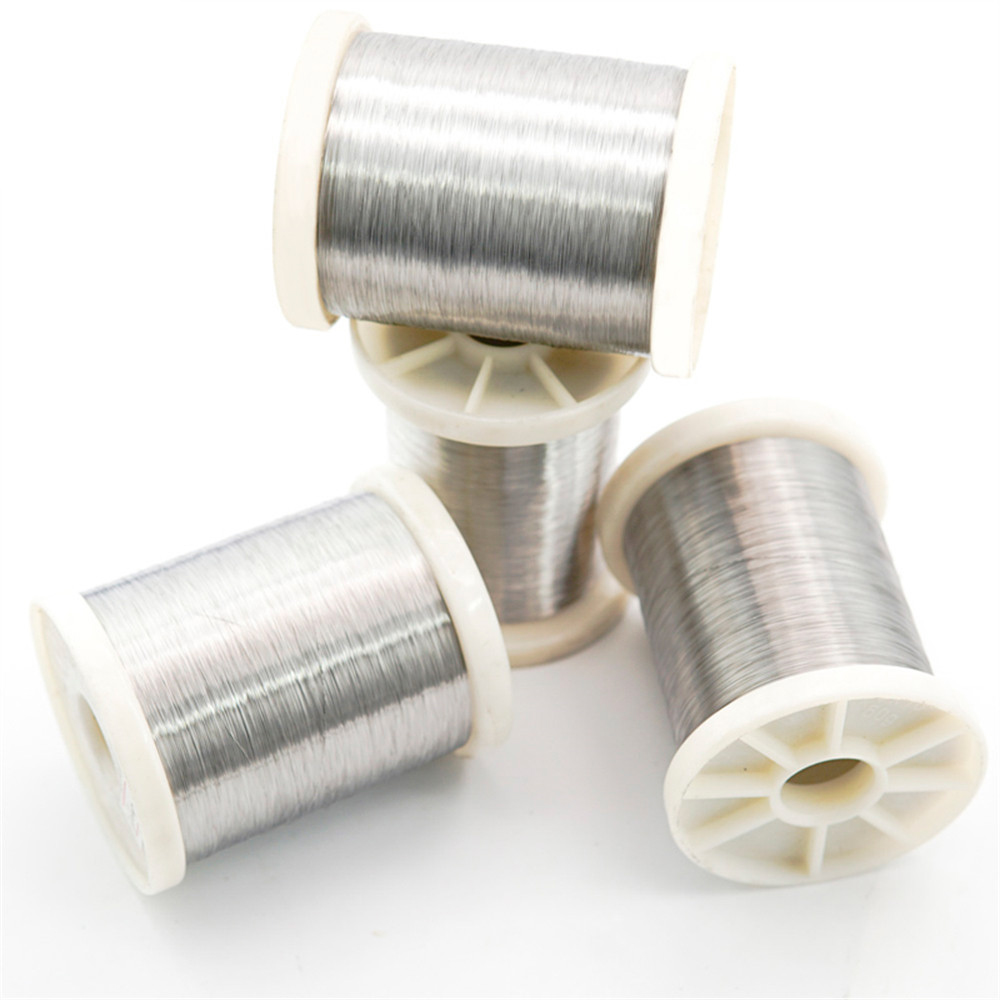

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more other size details, pls directly contact us.

Introduce:

CuNi30

Nickel content: about 30%

Properties: High nickel content provides excellent corrosion resistance, especially at high temperatures and chemically active environments.

Application: Often used to manufacture equipment that operates under extreme conditions, such as chemical processing equipment, subsea pipeline systems, etc.

CuNi34

Nickel content: about 34%

Features: The further increased nickel content enhances the material's corrosion resistance and heat resistance while maintaining good processing properties.

Application: Suitable for high-performance heat exchangers, chemical reactors and other equipment used in high temperature or corrosive environments.

CuNi40

Nickel content: about 40%

Characteristics: The high nickel content gives CuNi40 excellent corrosion resistance, especially in high temperature oxidizing environments.

Application: Suitable for manufacturing industrial components that require extremely high corrosion resistance and high temperature resistance, such as heat exchangers, boiler components, etc.

CuNi44

Nickel content: about 44%

Alias: white copper

Properties: The very high nickel content gives CuNi44 excellent corrosion resistance, especially in salt water and acidic environments.

Application: Widely used in marine engineering, chemical industry, and as high corrosion resistance resistance wire material.

Common characteristics:

Corrosion Resistance: These copper-nickel alloys all have excellent corrosion resistance, especially in chemical and marine environments.

Processability: These alloys have good processability and can be made into the desired resistance wire shape and size through various processes.

High strength: Compared to pure copper, copper-nickel alloys exhibit higher mechanical strength and hardness.

Thermal stability: No phase change occurs during hot and cold processing, ensuring the consistency of the mechanical properties and corrosion resistance of the alloy.

Application areas:

Marine engineering: ships, offshore platforms, seawater desalination equipment, etc.

Chemical industry: corrosion-resistant pipes, valves, pumps and heat exchangers, etc.

Precision instruments: thermocouples, resistors, and other resistive components that require high precision and stability.

Electric power industry: used as heating wire to manufacture heating cables, snow melting systems, etc.

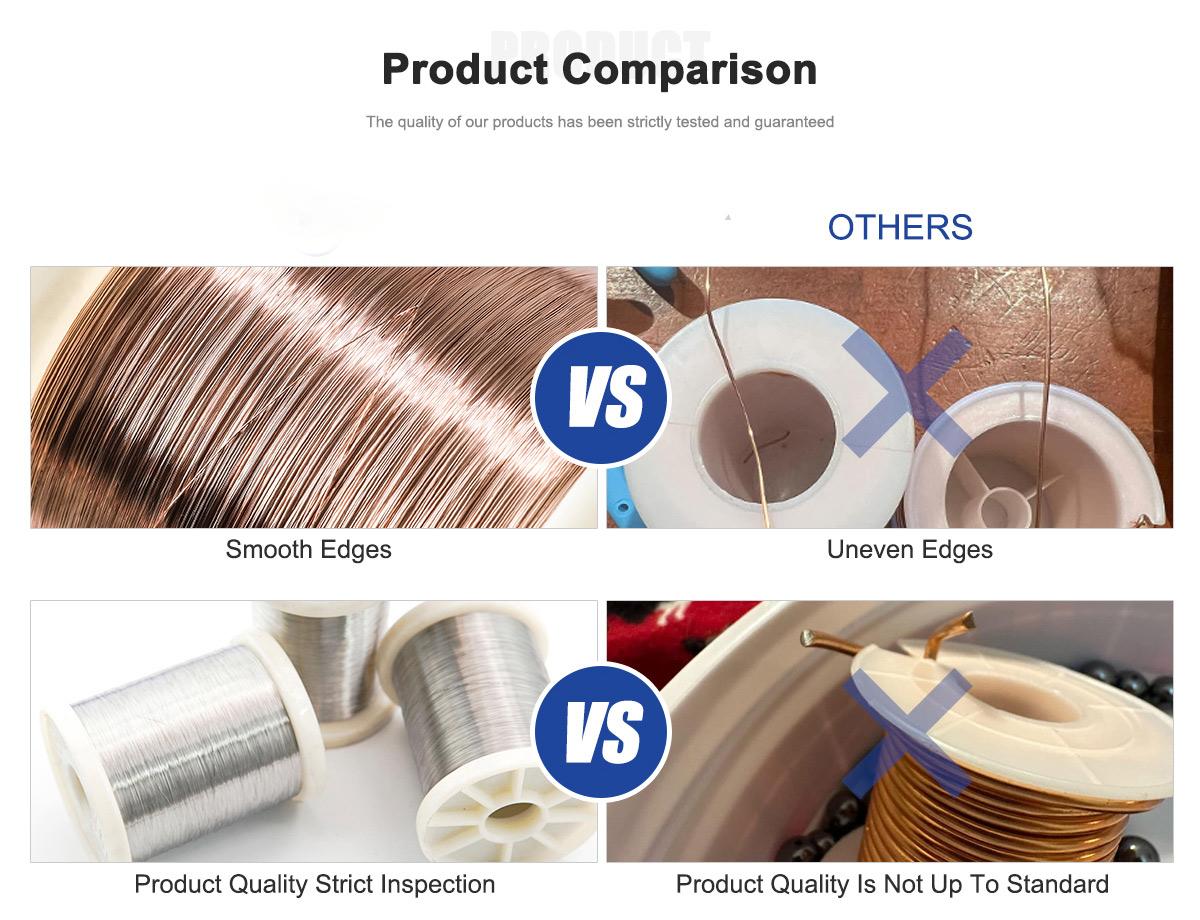

Common quality inspection methods:

Resistance value test: Accurately measure the resistance value of copper-nickel resistance wire by using professional resistance measuring instruments. This ensures that the resistance wire conforms to the specified resistance value range to meet the requirements of the specific application.

Diameter measurement: Use a high-precision diameter measuring instrument to measure the diameter of the copper-nickel resistance wire. Precise diameter control is critical to ensure the stability and reliability of resistance wire during processing and application.

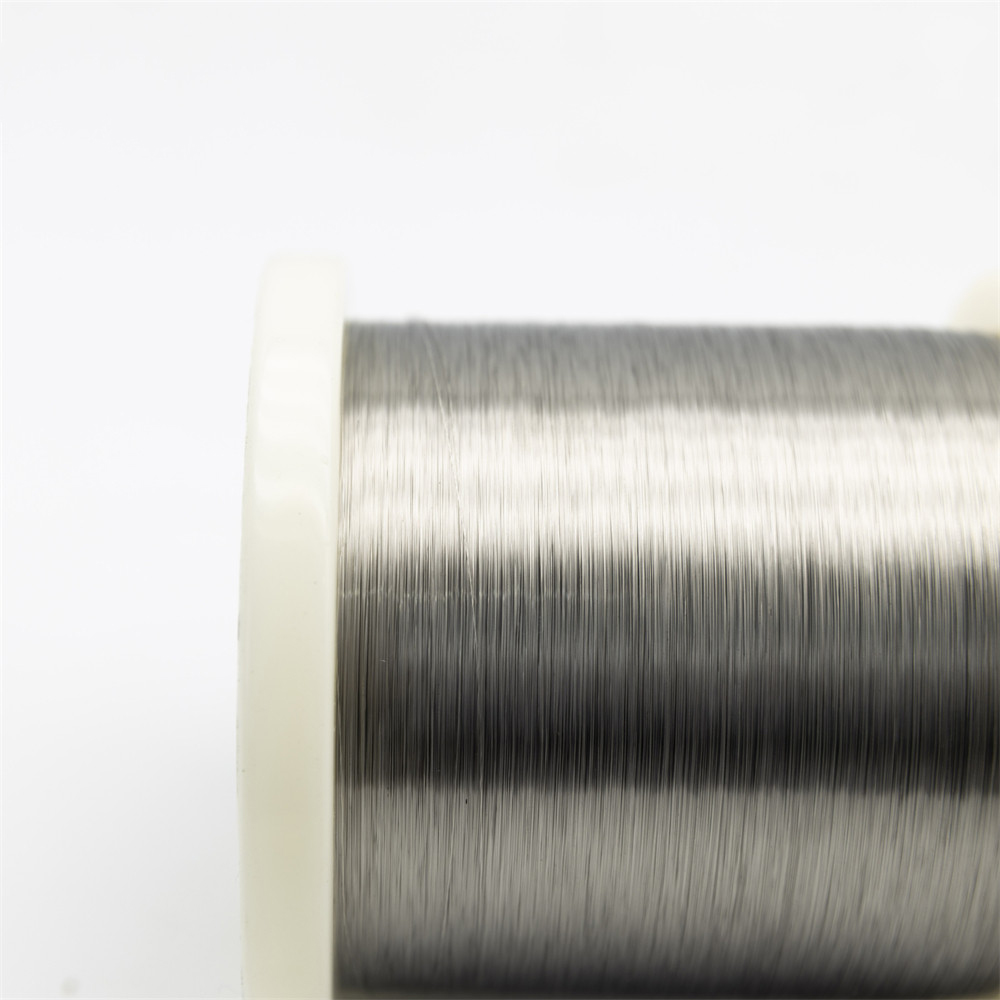

Surface quality inspection: Visually inspect the surface of the copper-nickel resistance wire or use tools such as a microscope to check its surface quality. Make sure the surface is smooth and free of obvious defects or stains to improve its electrical conductivity and corrosion resistance.

Tensile testing: Tensile testing was performed to evaluate the mechanical properties of copper-nickel resistance wires. This includes measuring indicators such as its tensile strength, yield strength and elongation to ensure that the product is not prone to breaking or deforming during use.

Chemical composition analysis: Use chemical analysis methods to detect and analyze the chemical composition of copper-nickel resistance wires. This helps ensure that the alloy composition meets specified requirements to ensure it has the required electrical and mechanical properties.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China