0

0

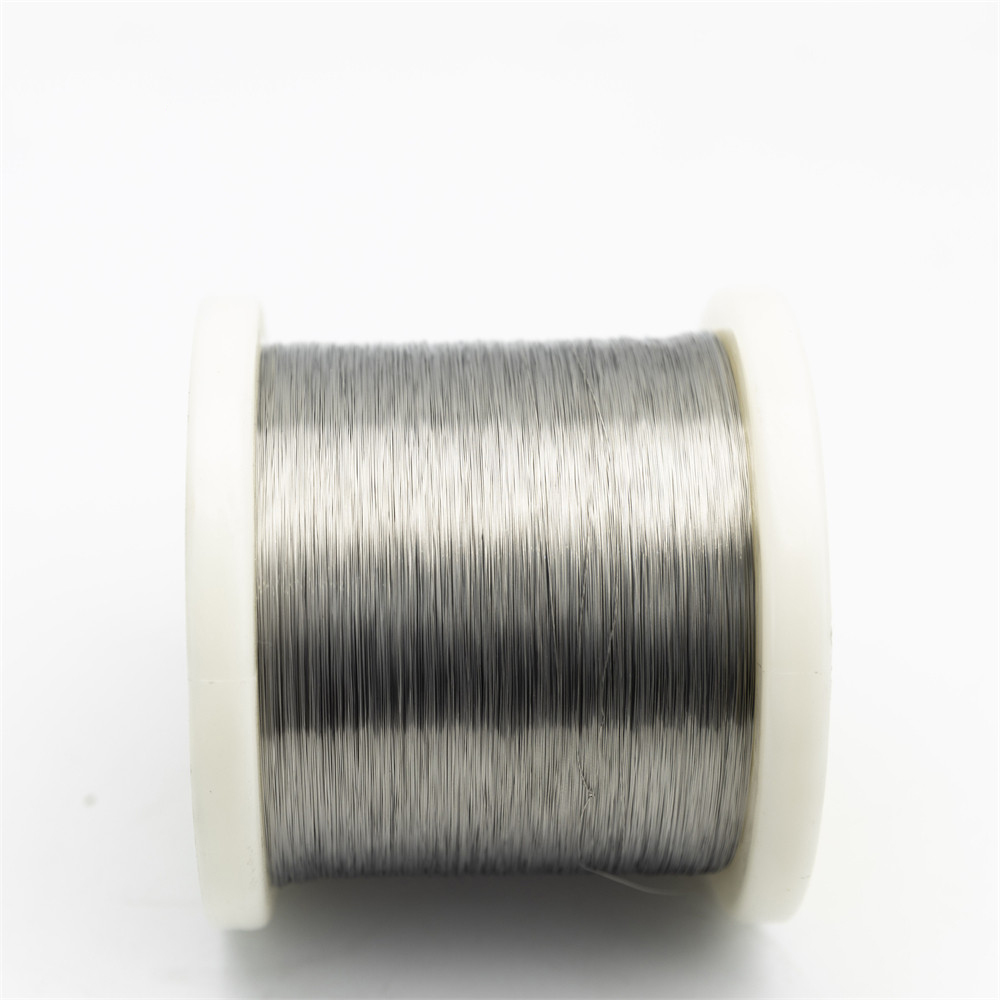

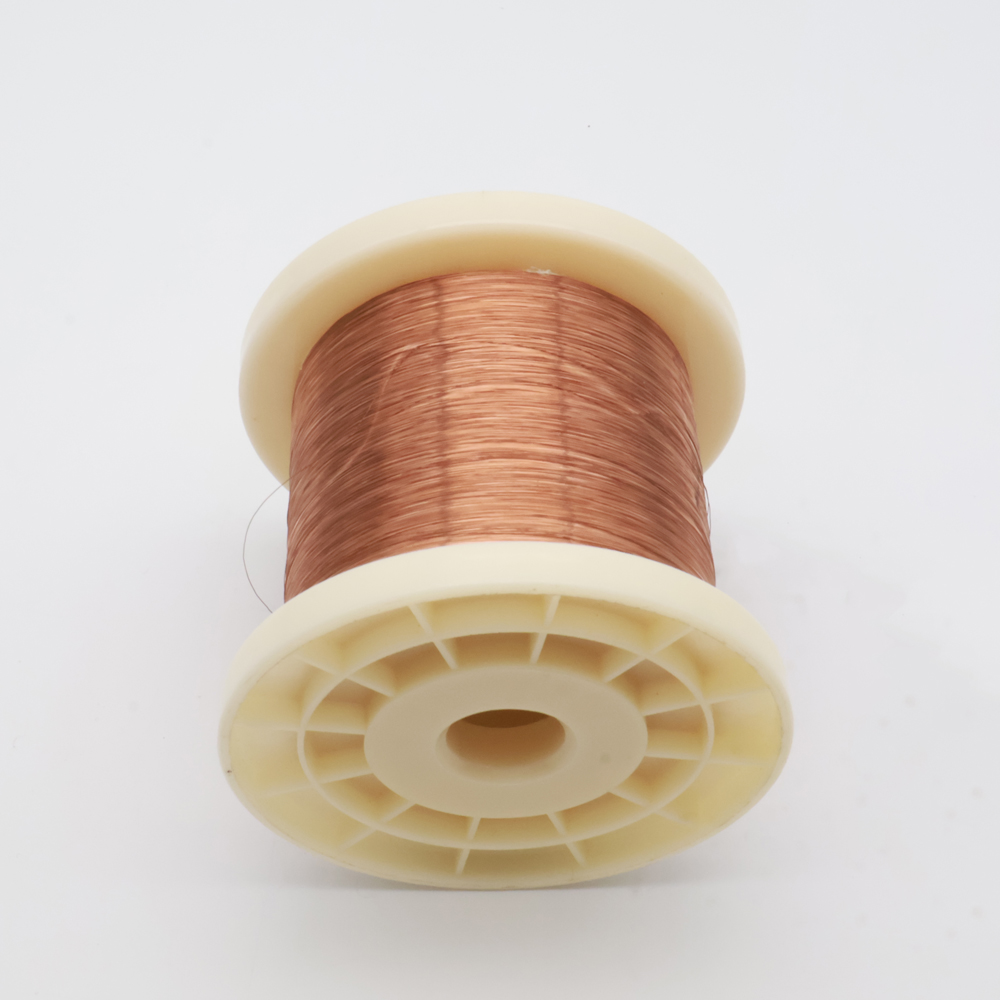

Products Description

Copper-nickel alloy is an important type of alloy material, usually composed of copper (Cu) and nickel (Ni) in different proportions. These alloys are known for their excellent electrical conductivity, corrosion resistance, and mechanical properties and are therefore widely used in various industrial applications.

Common grades of CuNi alloys include CuNi1, CuNi2, CuNi10 and CuNi44. These grades represent different alloy compositions and performance characteristics. For example, CuNi1 and CuNi2 are typical low-copper alloys with higher copper content and are suitable for applications requiring higher electrical conductivity. CuNi10 and CuNi44 are alloys with higher nickel content, higher corrosion resistance and heat resistance, and are suitable for use in high temperature environments.

In addition, CuNi alloy also has some special alloy models, such as 6J8, 6J11 and 6J13, etc. They usually refer to alloys that meet specific standards or design requirements. These alloys may have specific thermal expansion coefficients, resistivities, and other properties that can be used in applications such as temperature sensors, resistors, and more.

The parameters of CuNi alloy include its composition, physical properties and chemical properties. Generally speaking, the composition of CuNi alloys can be adjusted according to specific grades and application requirements to achieve different performance goals. In terms of physical properties, CuNi alloys usually have good processability, weldability and heat treatability, and can be processed and adjusted as needed. In terms of chemical properties, CuNi alloy has good corrosion resistance and can work stably for a long time in a variety of environments.

Specification

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more other size details, pls directly contact us.

Feature

Excellent electrical conductivity properties: Copper-nickel alloys are favored for their good electrical conductivity properties. Its electrical conductivity is close to that of pure copper, making it an important material in the field of electrical engineering.

Good corrosion resistance: Copper-nickel alloy has excellent corrosion resistance and can work stably for a long time in a variety of harsh environments, which makes it widely used in marine engineering, chemical industry and other fields.

Excellent mechanical properties: Copper-nickel alloy has good mechanical properties, including strength, hardness and toughness. This makes it suitable for the manufacture of various mechanical parts and structural parts.

Good thermal stability: Copper-nickel alloy is stable in high-temperature environments and has good heat resistance, and can be used in the manufacturing of high-temperature processes and high-temperature equipment.

Good processability: Copper-nickel alloys are easy to process into various shapes and can be processed by forging, rolling, drawing and other methods, making them have broad application prospects in industrial production.

Corrosion resistance

Seawater corrosion resistance: Copper-nickel wire is particularly suitable for marine environments and can resist corrosion from salty and sulfur-containing substances in seawater. Therefore, it is widely used in ships, ocean platforms, seawater desalination equipment, etc.

Resistant to chemical media: Copper-nickel wire has good corrosion resistance to a variety of chemical media, including acidic, alkaline and neutral solutions, and is suitable for use in the chemical industry.

Oxidation resistance: Copper-nickel wire can maintain good corrosion resistance at high temperatures, and its oxidation resistance makes it perform well in high-temperature applications.

Resistant to pitting corrosion and stress corrosion: The alloy composition of copper-nickel wire gives it the ability to resist pitting corrosion and stress corrosion, which is very important in many demanding applications.

Self-healing ability: The passivation film formed on the surface of the copper-nickel wire can repair itself after being damaged and continue to maintain its corrosion resistance.

Long-term stability: Copper-nickel wire can maintain its corrosion resistance during long-term use and is not prone to performance degradation.

Environmental adaptability: Copper-nickel wire can maintain its corrosion resistance under a variety of environmental conditions, including temperature changes, pressure changes, etc.

The high corrosion resistance of copper-nickel wire mainly benefits from the following points:

Addition of nickel: Nickel is an excellent corrosion-resistant element. When added to copper, it can significantly improve the corrosion resistance of the alloy, especially in salty environments such as seawater.

Solid solution structure: Copper-nickel alloy forms a continuous α-single-phase solid solution. This structure prevents the alloy from phase change during hot and cold processing and maintains consistent corrosion resistance.

Passivation performance: A dense passivation film is easily formed on the surface of copper-nickel alloy. This film can effectively isolate the contact between the alloy and the corrosive medium and improve its corrosion resistance.

Optimization of alloying elements: By adjusting other alloying elements (such as iron, manganese, zinc, etc.) and their proportions in the copper-nickel wire, the corrosion resistance can be further optimized.

Processing technology: Appropriate heat treatment and processing technology can enhance the corrosion resistance of copper-nickel alloys. For example, cold working can improve its strength and corrosion resistance.

Application

Electrical Engineering: Due to its excellent conductive properties, copper-nickel wire is often used in the manufacture of electrical components such as wires, cables, resistors, and inductors.

Marine Engineering: Due to its excellent corrosion resistance, copper-nickel alloy is often used in the manufacturing of pipelines, valves, ship equipment and other components in marine environments.

Chemical industry: Copper-nickel wire is often used in the chemical industry to manufacture corrosion-resistant equipment, reactors, heat exchangers, etc., and has good performance in highly corrosive media.

High temperature process: Due to its good heat resistance, copper-nickel alloy is widely used in high-temperature equipment and high-temperature processes, such as heat treatment furnaces, high-temperature heat exchangers, etc.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China