0

0

Products Description

Pure nickel rod is a metal material with excellent workability, which performs well in processing and forming.

Forgeability: Pure nickel rod has good forgeability, that is, its shape can be changed by forging within a certain temperature range. It can be formed through hot forging, cold forging and other processes. By adjusting parameters such as temperature and strain rate, the shape and size of the pure nickel rod can be controlled. Forgeability allows pure nickel rods to adapt to different processing needs and meet the manufacturing requirements of complex parts.

Machinability: Pure nickel rods also show good machinability during processing. It can be processed through common cutting processing methods such as turning, milling, and drilling to achieve precise control of shape and size. Its lower cutting force and better cutting stability make pure nickel rods widely used in the fields of high-efficiency cutting and precision machining.

Weldability: Pure nickel rods have good weldability and can be connected and assembled by various welding methods. It can be welded with other metal materials, such as argon arc welding, resistance welding, laser welding, etc. Good weldability allows pure nickel rods to be easily connected with other components during the manufacturing and assembly process to achieve the assembly of complex components.

Stability of workability: Pure nickel rods show good stability during processing. Even under high temperature conditions, pure nickel rods can still maintain good processability and are not prone to deformation, cracking or damage. This enables pure nickel rods to have reliable performance in high-temperature processing and forming fields, such as high-temperature mold manufacturing and processing of thermal expansion and contraction compensation parts.

All in all, pure nickel rods are widely used in the manufacturing industry due to their good processability. Its forgeability, machinability, weldability and processing stability enable pure nickel rods to meet different processing needs, realize the manufacturing and processing of complex parts, and are widely used in aerospace, energy, chemical industry, electronics and other fields.

Features:

Easy to form: Pure nickel rods are easy to hot and cold process, and can be prepared into various shapes and sizes through forging, rolling, drawing and other forming processes.

Good plasticity: Pure nickel rods have good plasticity and can undergo plastic deformation during processing, making it easy to perform mold forming and deformation processing.

Good machinability: Pure nickel rods are easy to perform cutting processes, including turning, milling, drilling, etc., and can obtain high-precision workpiece surfaces.

Weldability: Pure nickel rods have good weldability and can be connected with other materials through welding technology to achieve the manufacturing of a variety of complex structures.

Parameter:

Chemical composition: Nickel (Ni) with a purity higher than 99.5%

Density: 8.9 g/cubic centimeter (g/㎝³)

Melting point: about 1455 degrees Celsius

Tensile strength: about 380 MPa

Yield strength: about 140 MPa (MPa)

Elongation: about 45%

Size Range | |

Wire | dia 0.025-10mm |

Ribbon | (0.05-0.2)*(0.5-6.0)mm |

Strip | (0.05-0.5)*(5-200)mm |

Plate | custom made |

Density | 8.89 g/cm3 |

Tensile Strength ksi (min) | 462 |

Yield Strength 0.2% ksi (min) | 148 |

Elongation δ5 (%) | 40 |

Melting point | 1435-1446°C |

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

For more details, pls directly contact us.

Influencing factors:

The machinability of pure nickel rods is affected by the following factors:

Temperature: Temperature is a key factor affecting the processability of pure nickel rods. Within an appropriate temperature range, pure nickel rods have good plasticity and machinability, and can obtain better processing results.

Purity: High-purity pure nickel usually has better processability. The presence of impurities may have a certain impact on processing performance.

Microstructure: Microstructural factors such as grain size, grain boundary state and phase composition of pure nickel rods also have an impact on processability. A fine, uniform grain structure often contributes to improved machinability.

Other advantages:

In addition to processability, pure nickel rod offers other advantages, including:

Good corrosion resistance: Pure nickel rod has excellent corrosion resistance and can resist the erosion of acid, alkaline, salt corrosion and other media.

Excellent high temperature performance: Pure nickel rods have excellent properties such as high strength, oxidation resistance and dimensional stability in high temperature environments.

Good thermal conductivity: Pure nickel rods have good thermal conductivity, can effectively conduct heat, and have advantages in heat transfer and heat dissipation.

Related application areas:

Due to its processability and other advantages, pure nickel rods are widely used in the following areas:

Aerospace industry: Pure nickel rods are used to manufacture aerospace engine parts, turbine blades and other high-precision and complex structural components.

Petrochemical industry: Pure nickel rods can be used to manufacture chemical equipment, petrochemical devices, catalysts, etc.

Electronic devices: Pure nickel rods can be used to manufacture electronic devices, thermal components, radiators, etc.

Laboratory and scientific research fields: Pure nickel rods can be used to prepare high-temperature experimental equipment, stoves, heat treatment devices, etc.

Other fields: Pure nickel rods can also be used in the electric power industry, automobile manufacturing, chemical industry, medical equipment and other fields to manufacture electric equipment, automobile parts, chemical reactors, medical equipment, etc.

Production Process:

Material preparation: Select high-purity nickel raw materials, usually electrolytic nickel, electrolytic powder nickel or other higher-purity nickel materials as starting materials. These raw materials undergo chemical analysis and screening to ensure that their chemical composition and purity meet requirements.

Smelting: Put the selected nickel raw materials into a high-temperature furnace for smelting. During the smelting process, the furnace temperature and atmosphere are controlled to completely melt the nickel raw material and achieve a uniform chemical composition. Through smelting, the nickel liquid obtained has high purity and a certain temperature.

Filtration and purification: Remove impurities and non-metallic inclusions from molten nickel liquid. Impurities are separated through filtration and purification processes, such as filters or centrifugal separators, to improve the purity and quality of pure nickel rods.

Continuous casting: Inject the purified nickel liquid into the continuous casting machine. The continuous casting machine controls the temperature and cooling rate to gradually solidify the nickel liquid and form continuous rod-shaped crystals. In this process, the diameter and length of the rod can be controlled to meet the needs of different applications.

Heat treatment: The nickel rods obtained by continuous casting are heat treated to eliminate internal stress and improve the crystal structure. Common heat treatment methods include annealing and solution treatment. Heat treatment can improve the mechanical properties and grain boundary structure of pure nickel rods to meet the requirements of specific applications.

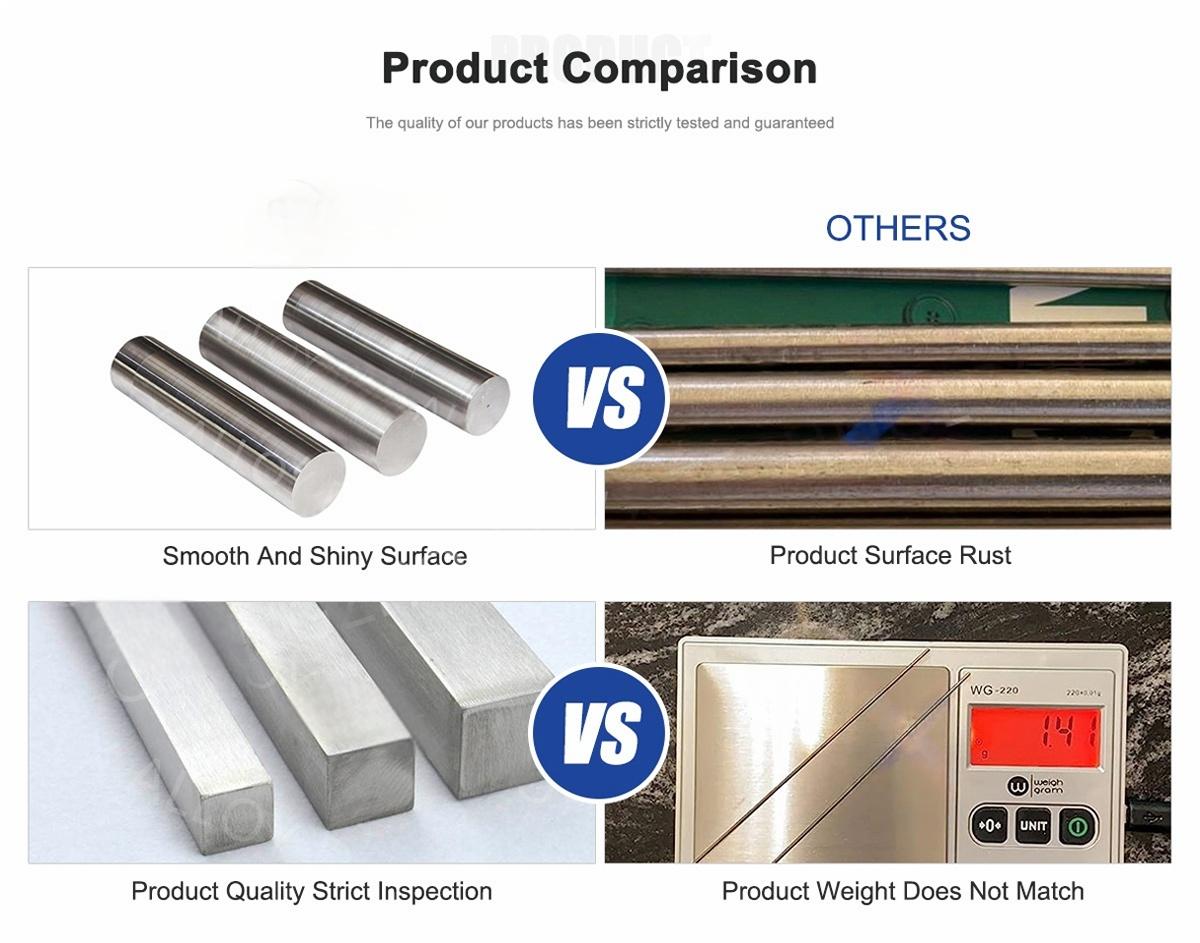

Surface Treatment: Heat-treated pure nickel rods may require surface treatment to remove oxide layers, contaminants, and roughness to obtain a smooth and clean surface. Surface treatment can use mechanical polishing, pickling, electrolytic polishing and other methods.

Inspection and quality control: A series of quality inspections such as appearance inspection, dimensional inspection, chemical composition analysis, and mechanical performance testing are conducted on the finished pure nickel rods. Ensure that pure nickel rods meet specified standards and quality requirements.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China