0

0

Products Description

Pure nickel rod is a metal material with excellent thermal conductivity properties. Thermal conductivity refers to the ability of a material to conduct heat, and pure nickel rods are widely used in many fields due to their high thermal conductivity.

First, pure nickel rods have high thermal conductivity. Thermal conductivity is a measure of a material's ability to conduct heat, indicating the amount of heat conducted per unit area per unit time. The high thermal conductivity of pure nickel rod means it can quickly transfer heat energy to other parts of the material, achieving thermal equilibrium. This makes pure nickel rod ideal for use in applications such as heat exchangers, radiators, thermal components and more.

Secondly, the thermal conductivity of pure nickel rods remains excellent under high temperature conditions. It can maintain high thermal conductivity in high temperature environments and will not significantly reduce thermal conductivity due to temperature increase. Therefore, pure nickel rods are widely used in high-temperature equipment, stoves, gas turbines and other fields to ensure efficient heat transfer and processing.

In addition, pure nickel rods also have good electrical conductivity properties. Conductivity refers to a material’s ability to conduct electricity, and the high conductivity of pure nickel rods makes it ideal for use in areas such as electronic components, circuit boards, and batteries. It can effectively transfer current and maintain the stability and efficient performance of the circuit.

The thermal conductivity of pure nickel rods also makes them play an important role in other fields. For example, it can be used to manufacture thermal management applications such as thermal components, temperature sensors, and heat pipes to control and regulate heat.

In short, pure nickel rods are widely used in many fields due to their excellent thermal conductivity. Its high thermal conductivity, high temperature stability and good electrical conductivity make it one of the indispensable materials in the fields of thermal management, energy transmission and electronics. Whether in high temperature environments or in circuit conduction, pure nickel rods can provide reliable thermal conductivity to meet the needs of various applications.

Features:

1. Nickel has good mechanical strength and ductility.

2. Excellent performance on corrosion-resistance.

3. High melting point.

4. With good weldability.

5. Low electrical resisitivity.

6. Electrical conductivity.

Parameter:

Chemical composition: Nickel (Ni) with a purity higher than 99.5%

Density: 8.9 g/cubic centimeter (g/㎝³)

Melting point: about 1455 degrees Celsius

Tensile strength: about 380 MPa

Yield strength: about 140 MPa (MPa)

Elongation: about 45%

Size Range | |

Wire | dia 0.025-10mm |

Ribbon | (0.05-0.2)*(0.5-6.0)mm |

Strip | (0.05-0.5)*(5-200)mm |

Plate | custom made |

Density | 8.89 g/cm3 |

Tensile Strength ksi (min) | 462 |

Yield Strength 0.2% ksi (min) | 148 |

Elongation δ5 (%) | 40 |

Melting point | 1435-1446°C |

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

For more details, pls directly contact us.

Influencing factors:

The thermal conductivity of pure nickel rods is affected by the following factors:

Temperature: Temperature is an important factor affecting the thermal conductivity of pure nickel rods. Generally speaking, the thermal conductivity of pure nickel decreases slightly as the temperature increases.

Purity: High-purity pure nickel generally has better thermal conductivity properties. The presence of impurities may have a certain impact on thermal conductivity.

Microstructure: Microstructural factors such as grain size, grain boundary state and phase composition of pure nickel rods will also affect the thermal conductivity. A fine, uniform grain structure often helps improve thermal conductivity.

Other advantages:

In addition to thermal conductivity properties, pure nickel rods offer other benefits including:

Good corrosion resistance: Pure nickel rod has excellent corrosion resistance and can resist the erosion of acid, alkaline, salt corrosion and other media.

Good high temperature performance: Pure nickel rods have excellent properties such as high strength, oxidation resistance and dimensional stability in high temperature environments.

Processability: Pure nickel rods are easy to process and form, and can be prepared into various shapes and sizes through a variety of processing methods.

Related application areas:

Due to its thermal conductivity properties and other advantages, pure nickel rods are widely used in the following areas:

Heat Exchangers: Pure nickel rods can be used to create efficient heat exchangers for heat transfer and cooling applications.

Electronic devices: Pure nickel rods can be used in electronic devices, radiators and thermal components to improve heat dissipation.

Welding materials: Pure nickel rods can be used for high temperature welding materials, providing good heat conduction properties.

Gas turbine: Pure nickel rods are widely used in gas turbines to manufacture high-temperature working parts such as turbine blades and combustion chamber components.

Laboratory and scientific research fields: Pure nickel rods can be used in high-temperature experimental equipment, stoves, heat treatment devices, etc.

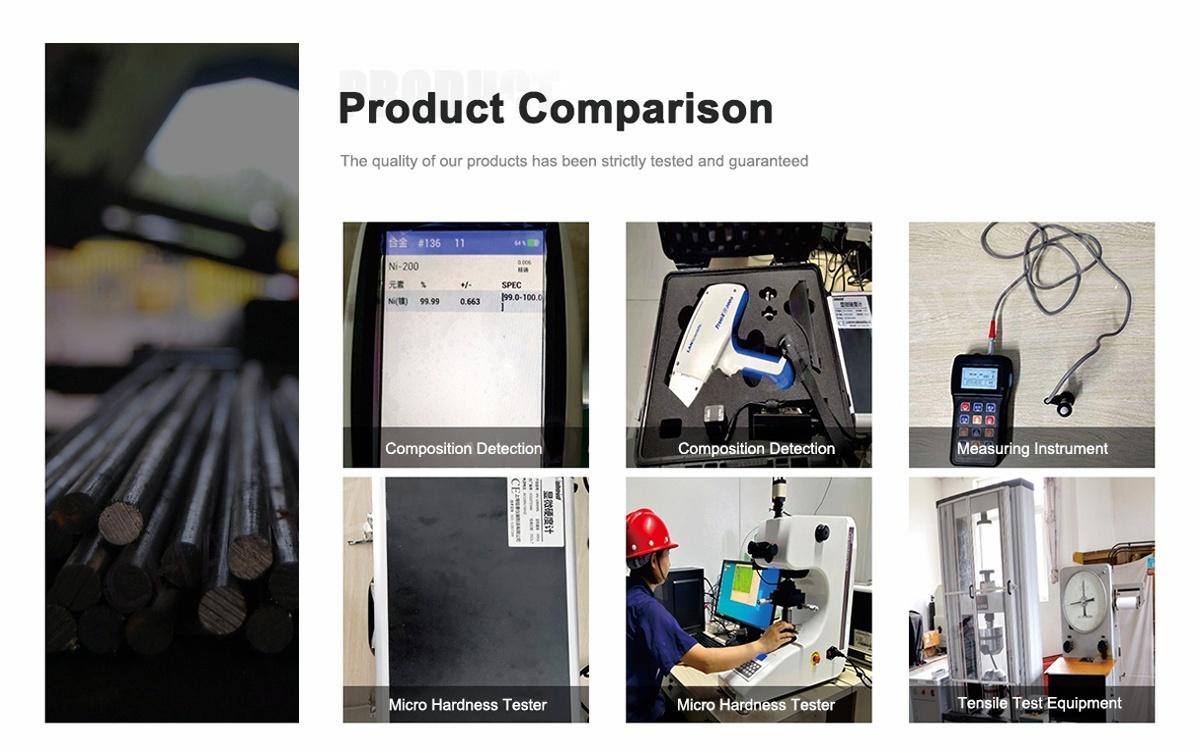

Quality Inspection:

Chemical composition detection: Through chemical analysis methods, the content of each element in the pure nickel rod is detected to ensure that it meets the specified composition requirements. Commonly used chemical analysis methods include spectral analysis, chemical titration and atomic absorption spectroscopy.

Mechanical property testing: The mechanical properties of pure nickel rods are crucial to their application performance. Common mechanical performance indicators include tensile strength, yield strength, elongation and hardness, etc. These indicators can be measured through tensile testing, hardness testing and impact testing.

Dimensional and appearance inspection: The size and appearance quality of pure nickel rods have an important impact on its processing and use. Dimensional inspection includes the measurement of parameters such as diameter, length and straightness, often using tools such as calipers, vernier calipers and optical measuring instruments. Appearance inspection includes evaluation of surface finish, surface defects and surface coating.

Corrosion performance testing: The corrosion resistance of pure nickel rods is one of its important characteristics. Corrosion performance testing can evaluate its performance in different corrosive media through methods such as immersion tests, salt spray tests, and electrochemical tests.

Welding performance testing: Pure nickel rods need to be welded in some applications, so their welding performance also needs to be evaluated. Common welding performance tests include weld strength testing, weld structure observation and welding deformation assessment.

These quality testing methods and indicators can be selected and implemented according to specific standards and requirements to ensure that the quality and performance of pure nickel rods meet expectations. During the production process, strict quality control and testing procedures are the key to ensuring the quality of pure nickel rods.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China