0

0

Products Description

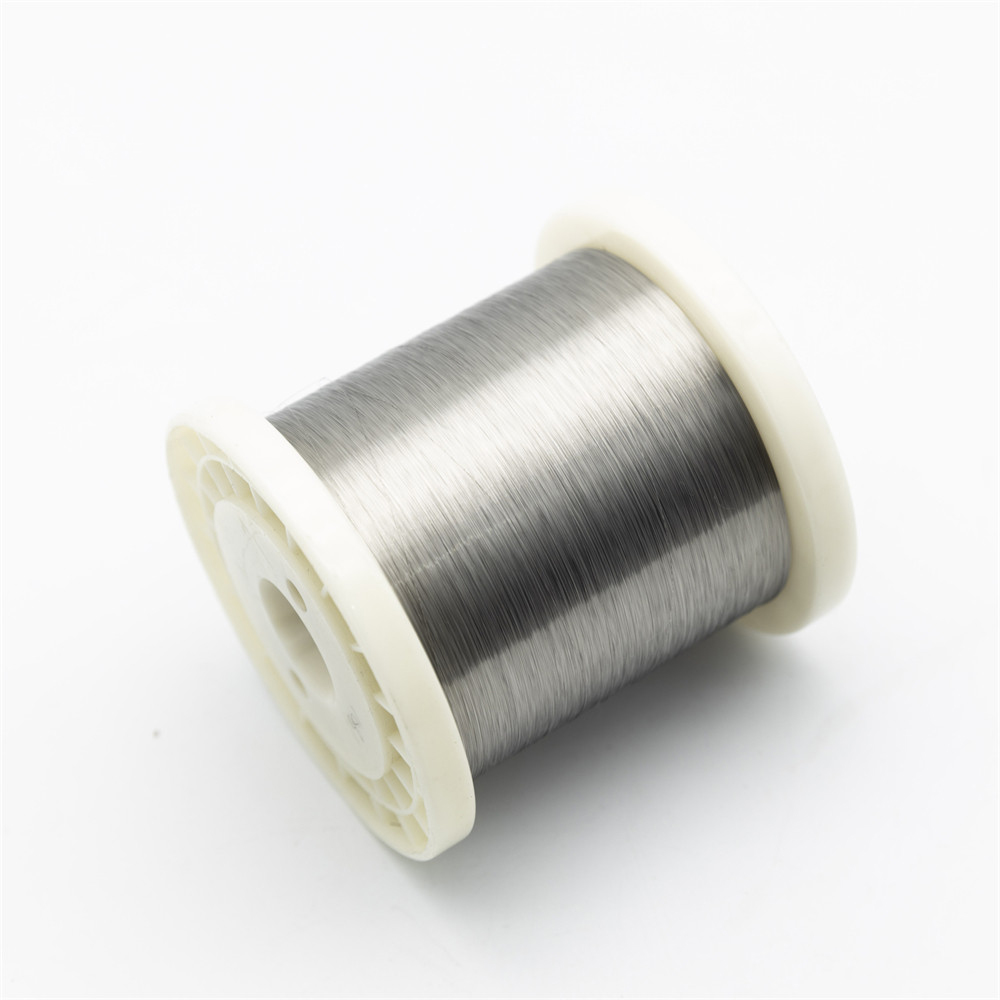

Nickel Alloy Cr15Ni60 Heating Wires Electric Resistance Wires

Cr15Ni60 resistance wire is a nickel chromium alloy material widely used in the industrial electric heating field due to its high electrical resistivity, good high-temperature strength, and oxidation resistance. This alloy is composed of approximately 15% chromium and 60% nickel, and can maintain good electric heating performance below 900 ℃, making it suitable for manufacturing various electric heating components. This alloy is widely used in electric heating components and high-temperature applications due to its excellent corrosion resistance, moderate electrical resistivity, and excellent high-temperature strength.

Parameter

Nichrome series: Cr10Ni90, Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni30, Cr20Ni35

Performance / material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

Resistivity at 20℃ (μΩ·m) | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

Specific heat (J/g.℃) | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

Thermal conductivity (KJ/m.h℃) | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

Coefficient of lines expansion a×10-6/(20~1000℃) | -- | 18 | 17 | 17 | 19 | 19 | |

Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

Magnetic properties | -- | Non-magnetic | Non-magnetic | Non-magnetic | Weak magnetic | Weak magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Feature

High resistivity, capable of generating large currents at lower voltages, achieving efficient heating.

Good high-temperature strength and antioxidant performance enable it to be used for a long time at high temperatures.

The excellent high resistance electric heating performance makes Cr15Ni60 widely used in electric heating equipment.

Good plasticity and corrosion resistance, can be processed into various shapes, such as round wire, strip, flat wire, etc.

Long service life, able to withstand repeated heating and cooling cycles.

Application

Electric heating equipment and heating elements, such as electric heaters, electric furnaces, and heat treatment furnaces.

Resistors and electric heating instruments are used for precise resistance measurement and control.

Heating elements in industrial processes and scientific experiments.

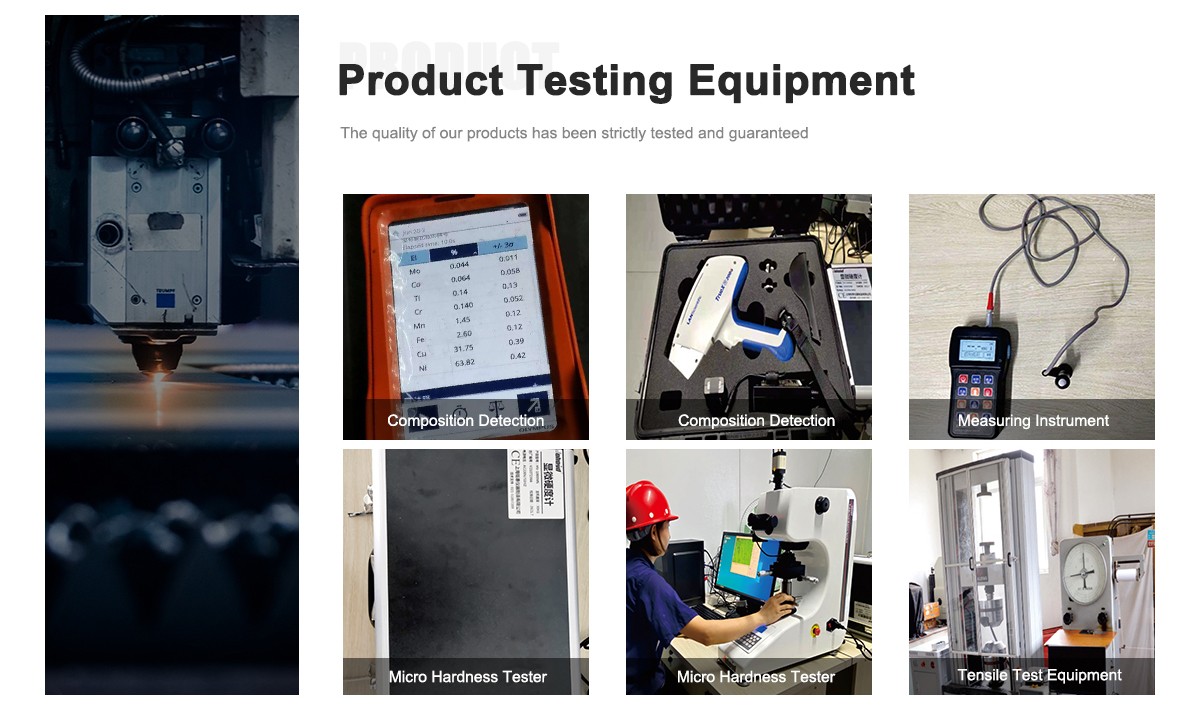

Quality inspection

Chemical composition analysis: Detecting the content of elements such as chromium, nickel, and iron in alloys through spectroscopic analysis or chemical analysis methods to ensure they meet established standards.

Dimensional accuracy: Measure the diameter, length, and other dimensions of the resistance wire to ensure they are within the specified tolerance range.

Resistivity test: Measure the resistivity of the resistance wire under standard conditions of 20 ° C to ensure it meets the specification requirements.

Mechanical performance testing: Conduct tensile testing to evaluate mechanical performance indicators such as tensile strength and elongation.

Q&A

Q: What is the approximate resistivity of Cr15Ni60 resistance wire?

A: The resistivity of Cr15Ni60 resistance wire is 1.12 at 20 ° C μ Ω · m.

Q: What are the main uses of Cr15Ni60 alloy?

A: Cr15Ni60 alloy is mainly used to manufacture electric heating elements that operate below 900 ℃, such as heating elements in periodic heat treatment furnaces, and high-end electric heating equipment.

Q: What are the steps involved in the production process of Cr15Ni60 resistance wire?

A: The production process of Cr15Ni60 resistance wire includes steps such as melting, forging, rolling, and drawing. It is necessary to strictly control the melting temperature and processing parameters to ensure product quality and stability.

Q: What are the mechanical properties of Cr15Ni60 alloy?

A: The mechanical properties of Cr15Ni60 alloy include tensile strength and elongation after fracture, with tensile strength ≥ 600 MPa and elongation after fracture ≥ 20%.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China