0

0

Products Description

Nichrome Wire NiCr Alloy Resistance Winding Spiral Coil Heating Wire For Vacuum Furnace Heating Element

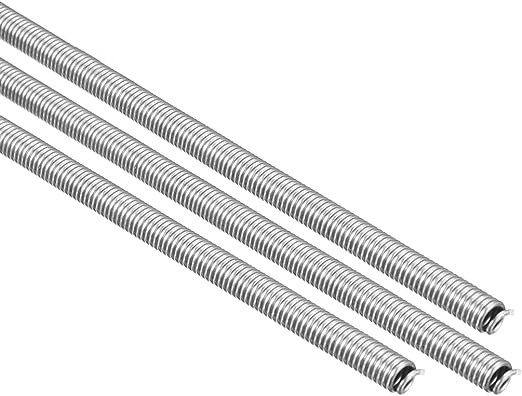

NiCr heating coil wire, short for Nickel-Chromium heating coil wire, is a type of resistance wire commonly used in heating applications. It is made of an alloy composed primarily of nickel and chromium, typically with a ratio of 80% nickel to 20% chromium (NiCr80/20) or 70% nickel to 30% chromium (NiCr70/30), although other compositions exist as well.

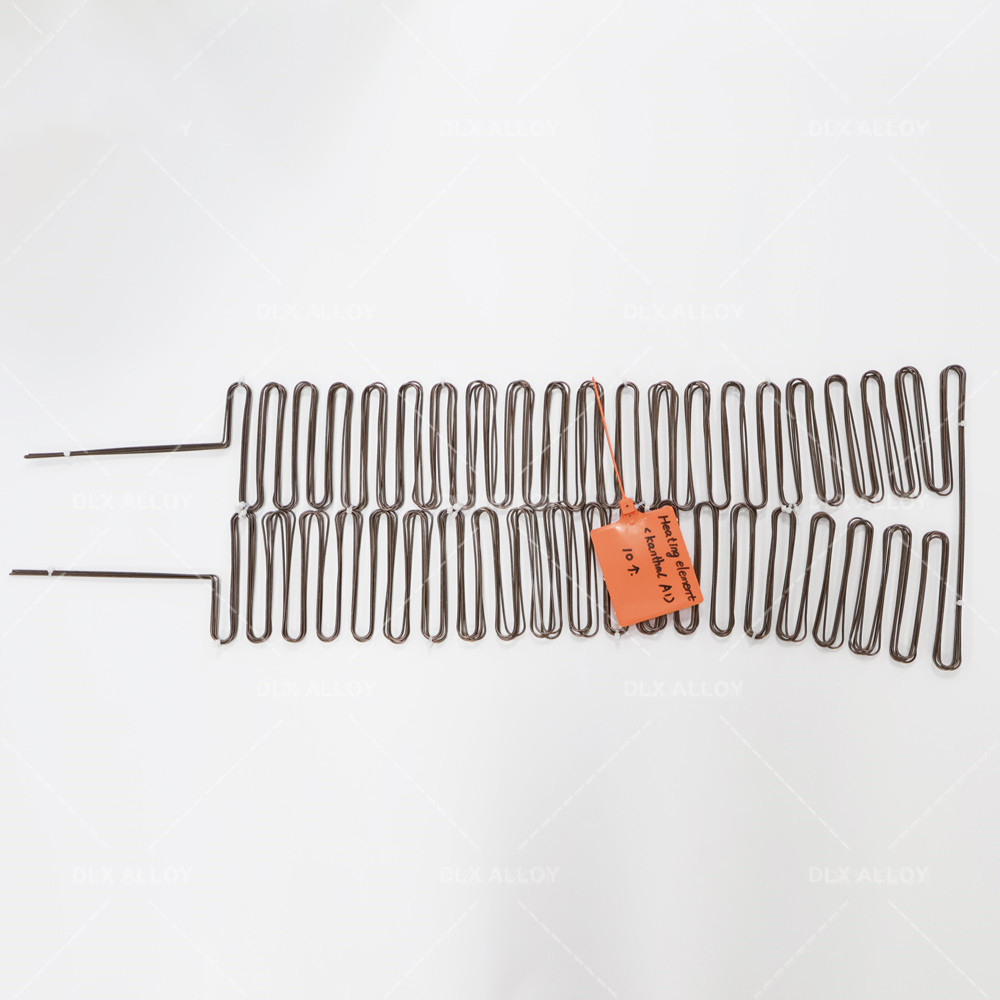

NiCr heating coil wire is known for its high resistance to oxidation and its ability to maintain stable electrical resistance at high temperatures. It is often formed into coils or straight lengths and used as the heating element in various applications, including electric stoves, ovens, heating pads, industrial furnaces, and many other heating devices.

The wire's specific composition and diameter can be selected based on the desired electrical resistance, operating temperature, and heating requirements of the application. It offers excellent heat generation efficiency and uniform heating, making it a popular choice for both industrial and domestic heating purposes. Additionally, it can be easily shaped and manipulated to fit specific heating element designs, providing versatility and reliability in various heating applications.

Parameter

Nichrome series: Cr10Ni90, Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni30, Cr20Ni35

Performance / material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

Resistivity at 20℃ (μΩ·m) | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

Specific heat (J/g.℃) | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

Thermal conductivity (KJ/m.h℃) | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

Coefficient of lines expansion a×10-6/(20~1000℃) | -- | 18 | 17 | 17 | 19 | 19 | |

Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

Magnetic properties | -- | Non-magnetic | Non-magnetic | Non-magnetic | Weak magnetic | Weak magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Feature

High temperature stability: NiCr heating wires have excellent high temperature stability, which can maintain stable performance under extreme temperature conditions and are not easily oxidized or brittle.

Resistance stability: This type of heating wire has good resistance stability, and even in long-term use and high temperature environments, the resistance value can remain relatively stable, ensuring consistent heating effect.

Corrosion resistance: NiCr alloy has high corrosion resistance, which can resist a certain degree of chemical corrosion and prolong the service life of heating wires.

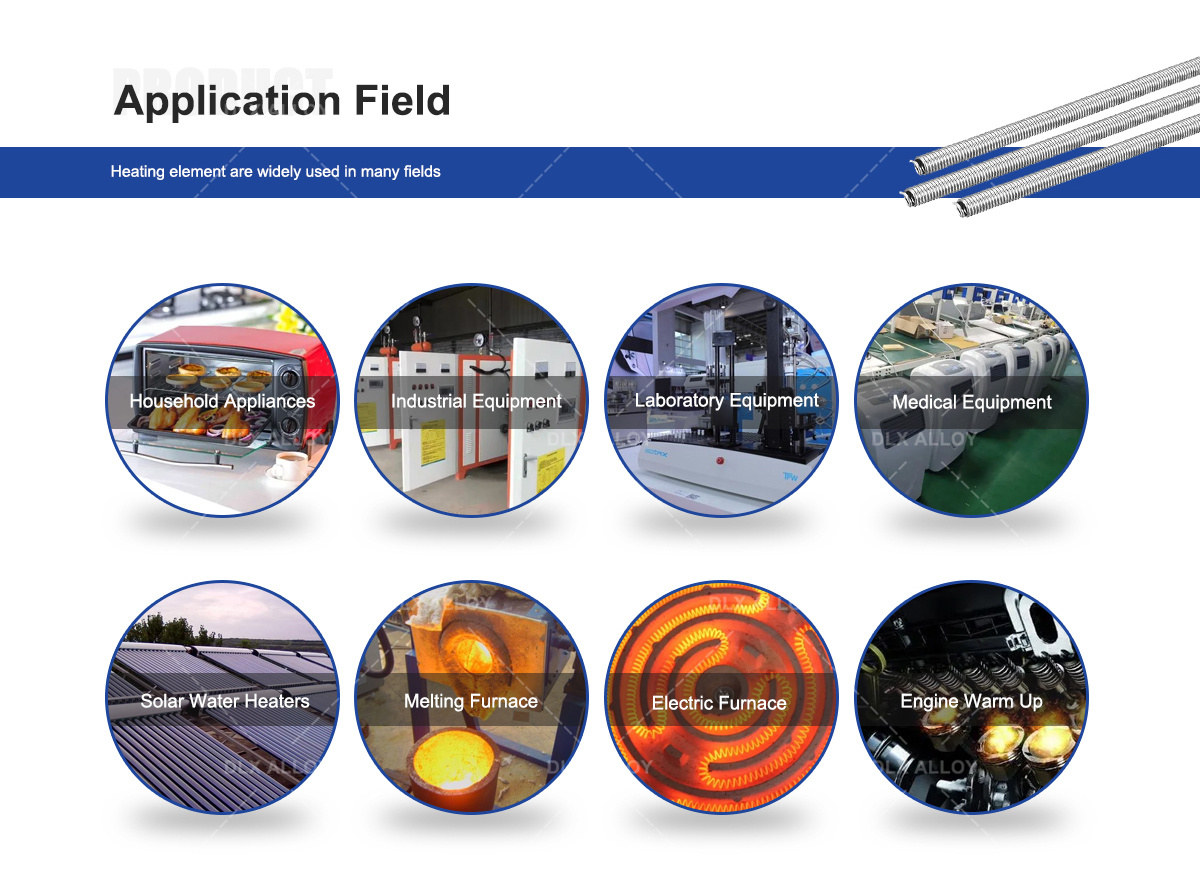

Application

Household appliances: NiCr heating wires are widely used in household appliances, such as electric kettles, electric stoves, dryers, etc., as heating elements, providing fast and uniform heating effects.

Industrial heating equipment: In the industrial field, NiCr heating lines are used as heating elements and are applied to various industrial heating equipment, such as heat treatment furnaces, melting furnaces, glass processing equipment, etc., to provide efficient heating solutions.

Laboratory and research: NiCr heating wires are also widely used in laboratories and research fields, for heating various experimental equipment and research devices, such as heating reactors in chemical experiments and heating devices in physical experiments.

Q&A

Q: How stable is the NiCr heating wire in high temperature environments?

Answer: NiCr heating wires have excellent high-temperature stability and can work for long periods of time without failure under extreme temperature conditions.

Q: What is the role of NiCr heating wires in household appliances?

Answer: NiCr heating wires act as heating elements in household appliances, converting electrical energy into thermal energy for heating water, food, or air.

Q: How is the corrosion resistance of NiCr heating wires?

Answer: NiCr heating wires have high corrosion resistance and can resist a certain degree of chemical corrosion, making them suitable for various environments and application scenarios.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China