0

0

Products Description

Furnace Heating Element Nichrome Heating Resistance Wire Cr30ni70

Cr30Ni70 resistance wire is a high nickel chromium alloy with excellent high-temperature strength and oxidation resistance, suitable for high-temperature heating elements used below 1150 ℃. The chemical composition of this alloy is 70% nickel and 30% chromium, providing good corrosion resistance, especially in the chemical industry, petroleum industry, and food processing fields. The resistivity and maximum operating temperature of Cr30Ni70 resistance wire are higher than other common Cr Ni alloys, such as Cr20Ni80 and Cr15Ni60, and its resistance temperature coefficient is also higher, which makes it very popular in the application of high-temperature heating elements.

Parameter

Nichrome series: Cr10Ni90, Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni30, Cr20Ni35

Performance / material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

Composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

Density g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

Resistivity at 20℃ (μΩ·m) | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

Specific heat (J/g.℃) | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

Thermal conductivity (KJ/m.h℃) | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

Coefficient of lines expansion a×10-6/(20~1000℃) | -- | 18 | 17 | 17 | 19 | 19 | |

Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

Magnetic properties | -- | Non-magnetic | Non-magnetic | Non-magnetic | Weak magnetic | Weak magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-40) |

For more details, pls directly contact us.

Feature

High resistivity and low resistance temperature coefficient ensure stable resistance at high temperatures.

Good corrosion resistance, suitable for various corrosive media.

High temperature strength can maintain structural stability and strength in high-temperature environments.

Excellent high-temperature performance, suitable for industrial high-temperature electric furnaces and other high-temperature applications.

Good processing performance, including cold working and welding performance.

Long service life, able to withstand repeated heating and cooling cycles.

Application

Industrial electric furnaces, especially equipment that requires high-temperature heating elements.

High temperature heating elements in the chemical and petroleum industries.

Food processing equipment, as well as other electric heating elements that require corrosion resistance and high temperature performance.

Used as a heating element in periodic heat treatment furnaces, such as carburizing furnaces, bell type furnaces, etc.

High quality heat-resistant structural components, especially in high temperature and corrosive environments.

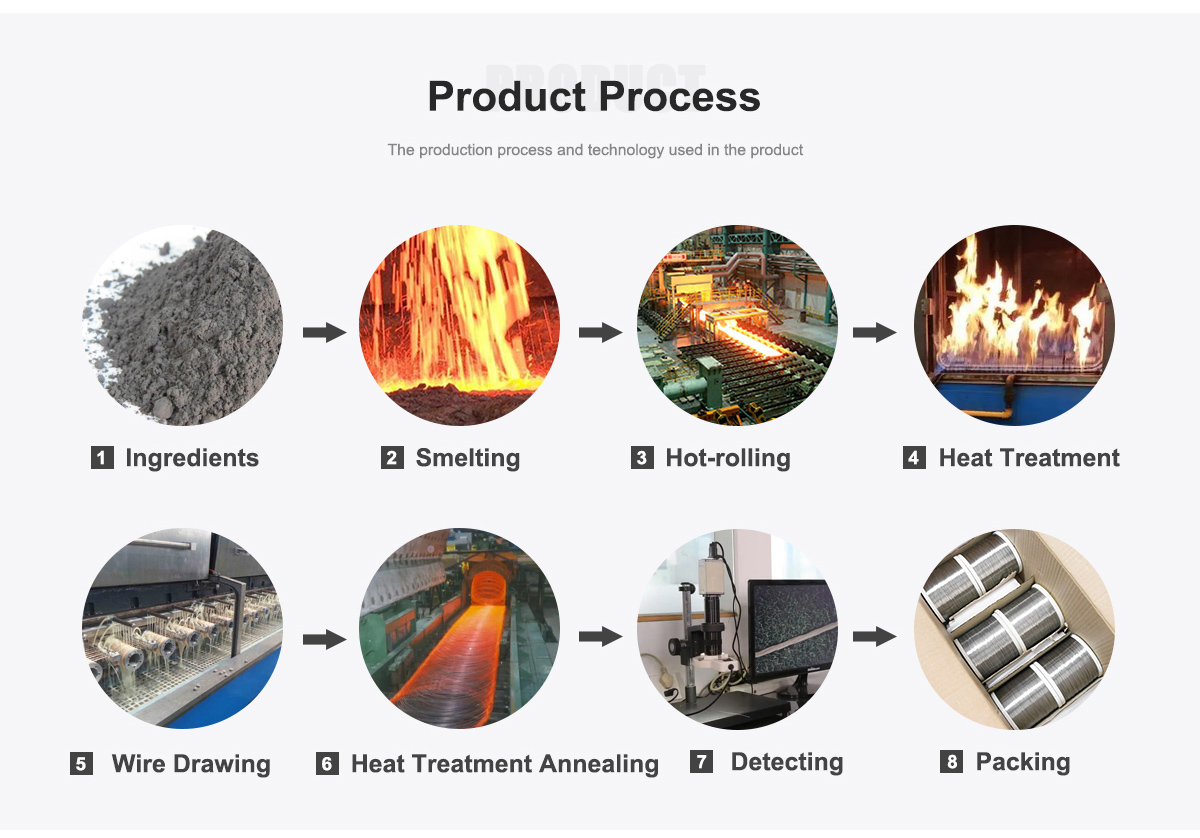

Process

Melting: Firstly, metal raw materials such as nickel and chromium are melted in a protective atmosphere to ensure the purity of the alloy.

Rolling: Hot rolling is performed on the alloy ingots obtained from melting to form plates or bars of different thicknesses.

Wire drawing: The rolled alloy material is gradually refined through a wire drawing machine to form a resistance wire of the required diameter.

Heat treatment: The resistance wire after drawing needs to undergo appropriate heat treatment, such as annealing, to optimize its microstructure and physical properties.

Surface treatment: Clean and treat the surface of the resistance wire to remove oxides and impurities, ensuring a bright surface of the resistance wire.

Testing: Test the physical properties such as electrical resistivity, tensile strength, and elongation of the resistance wire to ensure that the product meets the standards.

Packaging: Finally, package the qualified resistance wire to protect it from damage during transportation and storage.

Q&A

Q: What is the maximum working temperature of Cr30Ni70 resistance wire?

A: The maximum working temperature of Cr30Ni70 resistance wire is 1150 ℃.

Q: What is the corrosion resistance of Cr30Ni70 alloy?

A: Cr30Ni70 alloy has good corrosion resistance to various corrosive media such as oxidation, acid, and alkali, which makes it widely used in chemical industry, petroleum industry, and food processing.

Q: What is the approximate resistivity of Cr30Ni70 resistance wire at 20 ° C?

A: The resistivity of Cr30Ni70 alloy is approximately 1.18 at 20 ° C μ Ω · m.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China