0

0

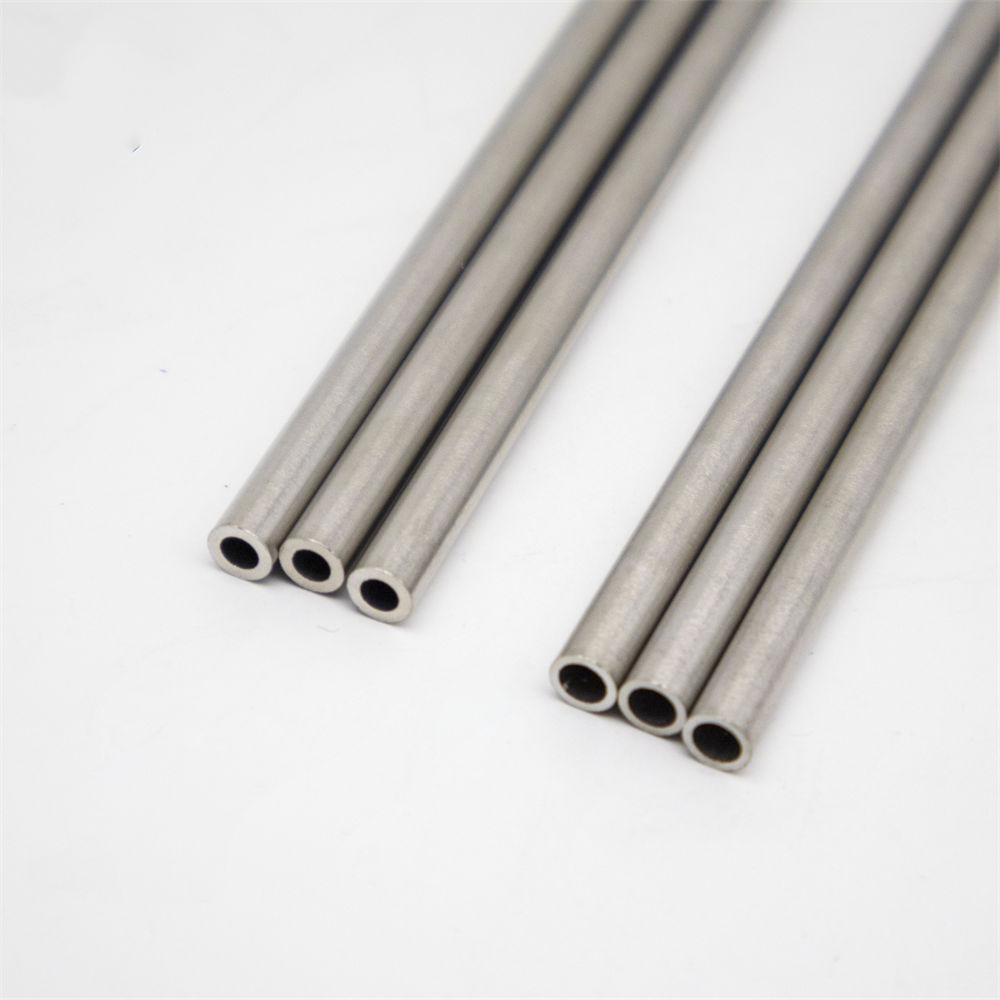

Products Description

Inconel pipe has a wide range of applications in the oil and gas industry. Inconel is a high-temperature alloy composed of nickel, chromium, iron and other elements and has excellent corrosion resistance, high-temperature strength and oxidation resistance.

Process conditions in the oil and gas industry are often very harsh, including high temperatures, high pressures, corrosive media and oxidizing environments. Under these harsh conditions, traditional materials often fail to meet the requirements, and Inconel pipes become the first choice due to their special alloy composition and performance advantages.

First of all, Inconel pipes have excellent corrosion resistance and show high stability in corrosive media such as acid, alkaline and chloride. This enables Inconel pipes to effectively resist pipeline damage and leakage caused by corrosion, ensuring the safe transportation of oil and natural gas.

Secondly, Inconel pipes have excellent high temperature strength and oxidation resistance. In high temperature environments, Inconel pipes can maintain high mechanical strength and stability and are not easily deformed and broken. At the same time, its anti-oxidation properties enable it to operate stably for a long time in a high-temperature oxidizing atmosphere and is not prone to oxide layers and corrosion.

In addition, Inconel pipes also have good welding performance and workability, which can meet the design and installation needs of complex pipeline systems. Its excellent mechanical properties and plasticity allow Inconel pipes to adapt to complex bending, flaring and connection requirements, ensuring the integrity and reliability of the pipeline system.

Parameter:

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Features:

Corrosion resistance: Inconel pipes have excellent corrosion resistance and can withstand corrosive media in the oil and gas industry, including acid, alkaline and salt water, extending the service life of pipelines.

High-temperature strength: Inconel pipes have excellent high-temperature strength and can withstand stress and thermal cycles in high-temperature and high-pressure environments, maintaining the structural stability and integrity of the pipeline.

Oxidation resistance: Inconel pipes have good antioxidant properties and can resist oxidation and thermal corrosion under high temperature conditions. They are suitable for high-temperature equipment and pipeline systems in the oil and gas industry.

Low wear: Inconel pipes have low wear characteristics, which can reduce pipeline losses caused by friction and wear and improve system efficiency and reliability.

Specific applications:

Oil well pipes: Inconel pipes are widely used in well pipes in oil and natural gas extraction. They can withstand high temperature, high pressure environments and corrosive media, ensuring the production and transportation of oil and natural gas.

Chemical Equipment: Inconel pipes are used in equipment and piping systems in the chemical industry, such as refineries, fertilizer plants and chemical processing units, providing corrosion resistance and high temperature performance to ensure safe and reliable production processes.

Natural gas transmission pipeline: Inconel pipes are used in natural gas transmission pipelines. They can resist corrosive components in natural gas and high-pressure environments, ensuring the safe and stable transportation of natural gas.

Q&A:

What advantages does Inconel pipe have over other materials in the oil and gas industry?

Inconel pipes have excellent corrosion resistance, high temperature strength and oxidation resistance, which can maintain stability in harsh industrial environments, extend the service life of pipelines, and improve system reliability.

What are the specific applications of Inconel pipes in oil well pipelines?

Inconel pipes are widely used in well pipelines in oil and natural gas extraction. They can withstand high temperature, high pressure environments and corrosive media, ensuring the production and transportation of oil and natural gas.

What are the advantages of Inconel pipes in natural gas transmission pipelines?

Inconel pipes have excellent corrosion resistance and high-temperature strength, and can withstand corrosive components in natural gas and high-pressure environments, ensuring safe and stable transportation of natural gas.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China