0

0

Products Description

Inconel pipe is a high-temperature alloy pipe made of nickel-based alloy Inconel. It has excellent high temperature resistance, corrosion resistance and oxidation resistance, and is widely used in aerospace, petrochemical, nuclear industry, electric power and other fields. The following is an introduction to some common Inconel pipe grades and their characteristics:

Inconel 600 (Grade: N06600): Inconel 600 is a nickel-chromium alloy with good corrosion resistance and high temperature strength. It has excellent oxidation resistance and creep resistance at high temperatures and is suitable for furnace tubes, heater tubes and petrochemical equipment in high temperature environments.

Inconel 625 (Grade: N06625): Inconel 625 is a nickel-chromium-molybdenum alloy with excellent corrosion resistance and high-temperature strength. It has high corrosion resistance to various corrosive media, including seawater, acidic solutions and alkaline solutions. Inconel 625 is commonly used in marine engineering, chemical equipment and nuclear industry.

Inconel 718 (Grade: N07718): Inconel 718 is a nickel-chromium-molybdenum-iron alloy with excellent high-temperature strength and corrosion resistance. It performs well in high temperatures and extreme environments and is commonly used in applications such as aerospace, petrochemicals and engine components.

Inconel 825 (brand: N08825): Inconel 825 is a nickel-chromium-iron alloy with excellent corrosion resistance, especially to sulfuric acid and sulfide media. It is commonly used in fields such as chemical equipment, marine engineering and petroleum processing.

These are common Inconel pipe grades, each with different chemical compositions and properties to meet the needs of different application scenarios. Whether it is high temperature, corrosion or high strength requirements, Inconel pipe provides a reliable solution.

Parameter:

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

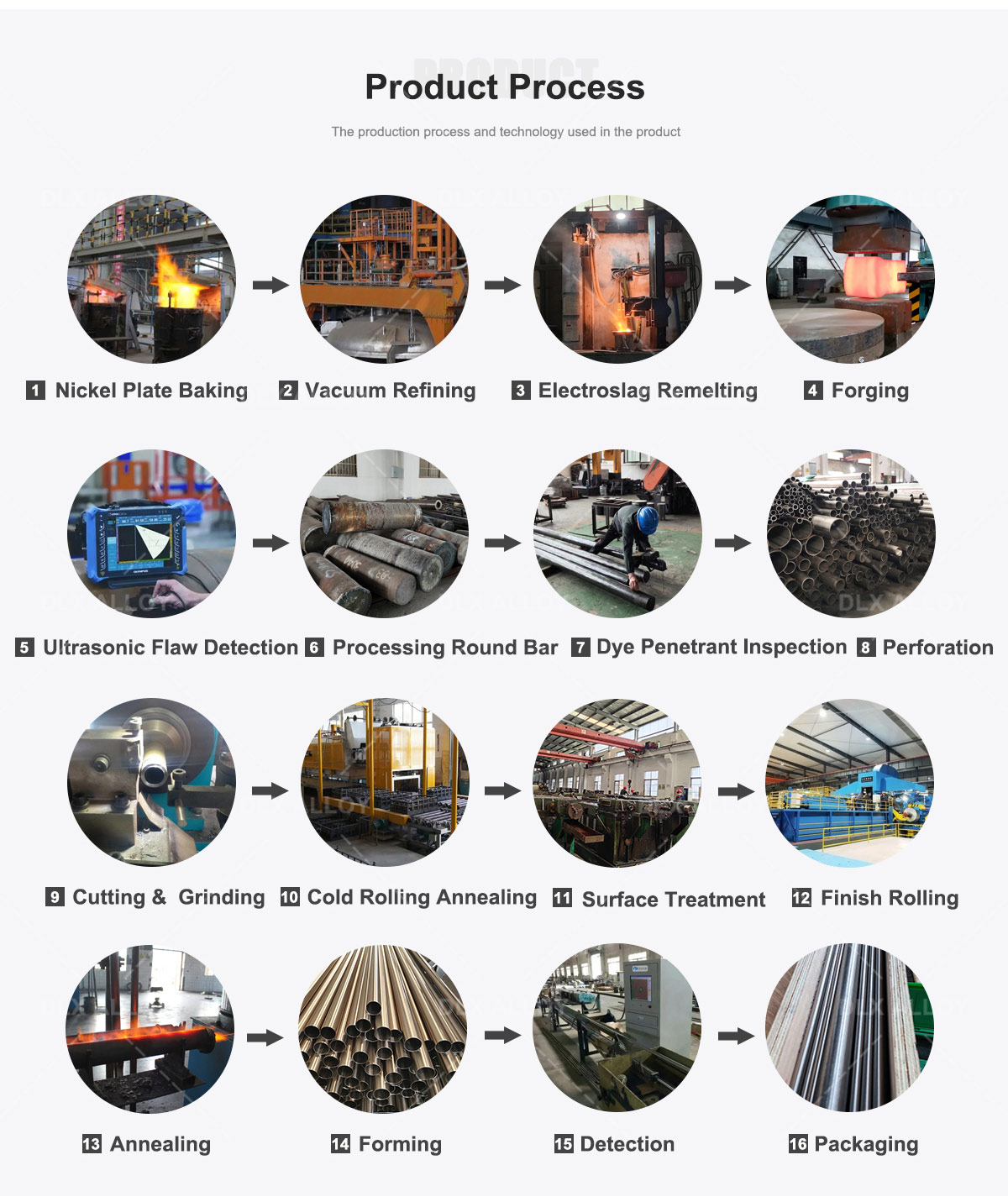

Product Process:

The production process of Inconel tubes usually covers the following key steps:

Raw material preparation: Select high-purity Inconel alloy as raw material. Inconel alloys usually contain elements such as nickel, chromium, and iron. The chemical composition and purity of the raw materials are controlled according to the requirements of the specific grade.

Melting: Place the selected Inconel alloy raw materials in the furnace for melting. Smelting can use smelting equipment such as electric arc furnaces, electroslag furnaces or vacuum induction furnaces. During the smelting process, the temperature and smelting time are controlled to fully melt the raw materials and form a uniform melt.

Continuous casting or hot rolling: Molten Inconel alloy is formed through continuous casting or hot rolling process. In the continuous casting process, the melt is injected into the continuous casting machine and cooled and solidified through the crystallizer to form a continuous cast slab. In the hot rolling process, the melt is poured into the casting mold, and after cooling, multiple passes of rolling are performed to gradually reduce the cross-sectional size to obtain the required tube blank.

Heat treatment: Perform heat treatment on Inconel tube blanks, including solution treatment and aging treatment. Solution treatment is to heat the tube blank to the solid solubility range of the alloy elements to uniformly dissolve the alloy elements. Aging treatment is to control the time and temperature after solid solution treatment to promote the precipitation of alloy elements and form a strengthening phase, thereby improving the strength and corrosion resistance of the pipe.

Pipe rolling: The heat-treated Inconel pipe blanks are rolled through cold rolling or hot rolling mills in multiple passes to gradually reduce the outer diameter and wall thickness of the pipe while improving its surface quality and mechanical properties. The rolling process can be rolled as many times as necessary and annealed to obtain the required pipe size and properties.

Cutting and shaping: Cut the rolled Inconel pipe, and cut it to length and shape as needed. Commonly used cutting methods include sawing, cutting, and cutter cutting. Shaping treatment can use equipment such as pipe benders and pipe expanders to bend or expand the pipe into the required shape.

Surface treatment: Surface treatment of Inconel pipes, such as pickling, polishing and electroplating, etc. Pickling can remove oxides and impurities on the surface of pipes and improve their surface quality. Polishing can further improve the surface finish and appearance of the pipe. Electroplating can form a protective coating on the surface of the pipe to improve its corrosion resistance.

Quality Inspection: Throughout the entire production process, Inconel tubes are inspected for quality. Including chemical composition analysis, physical performance testing, dimensional inspection, surface quality assessment, etc. These tests ensure that the quality of Inconel pipes meets relevant standards and requirements.

Packaging and leaving the factory: Inconel tubes that pass quality inspection are packaged and labeled to ensure the safety of their transportation and storage. The products are then shipped out of the factory and delivered to customers or used in applications in related fields.

Precautions:

There are some important considerations to consider during the production of Inconel pipe:

Material selection: Choose high-quality, standard-compliant Inconel alloy as raw material to ensure that its chemical composition and physical properties meet the requirements. Proper material selection is critical to ensuring pipe quality and performance.

Temperature control: Strict temperature control is necessary during processes such as smelting, heat treatment and rolling. Precise temperature control can ensure the uniformity of the alloy, grain refinement and accuracy of phase transformation, thereby improving the strength and corrosion resistance of the pipe.

Quality inspection: During the production process, comprehensive and strict quality inspection is essential. Including chemical composition analysis, physical performance testing, dimensional inspection, surface quality assessment, etc. Through quality inspection, any manufacturing defects can be discovered and corrected in time, ensuring that the quality of Inconel pipes produced meets standards and requirements.

Process control: Control all aspects of the production process to ensure that each step is operated in accordance with the specified process parameters. Including smelting, continuous casting or hot rolling, heat treatment, rolling and cutting, etc. Reasonable process control can ensure the dimensional accuracy, surface quality and stability of mechanical properties of pipes.

Q&A:

In which industries are Inconel pipes commonly used?

Inconel pipes are commonly used in industries such as the oil and gas industry, aerospace industry, chemical industry and nuclear industry.

What are the applications of Inconel pipe in the oil and gas industry?

Inconel pipes are used for pipeline transportation and processing in oil and gas extraction, refining and chemical processes.

What corrosive media can Inconel pipes withstand?

Inconel pipes can withstand a variety of corrosive media such as acids, alkalis, and salts, including sulfuric acid, chloride, and chlorine gas.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China