0

0

Products Description

Inconel pipe is a high-temperature alloy pipe composed of elements such as nickel, chromium and iron. It has excellent high temperature resistance, corrosion resistance and oxidation resistance, and is widely used in aerospace, petrochemical, energy and other fields. Inconel pipe has good mechanical properties and high strength, and can maintain stability in extreme temperatures and harsh environments. It also has excellent corrosion resistance and can resist the erosion of acids, alkalis, salts and oxidizing media. It is an important pipeline material and is suitable for high temperature, high pressure, corrosive media transportation and processing systems to ensure safe and reliable operation of the system.

Parameter:

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

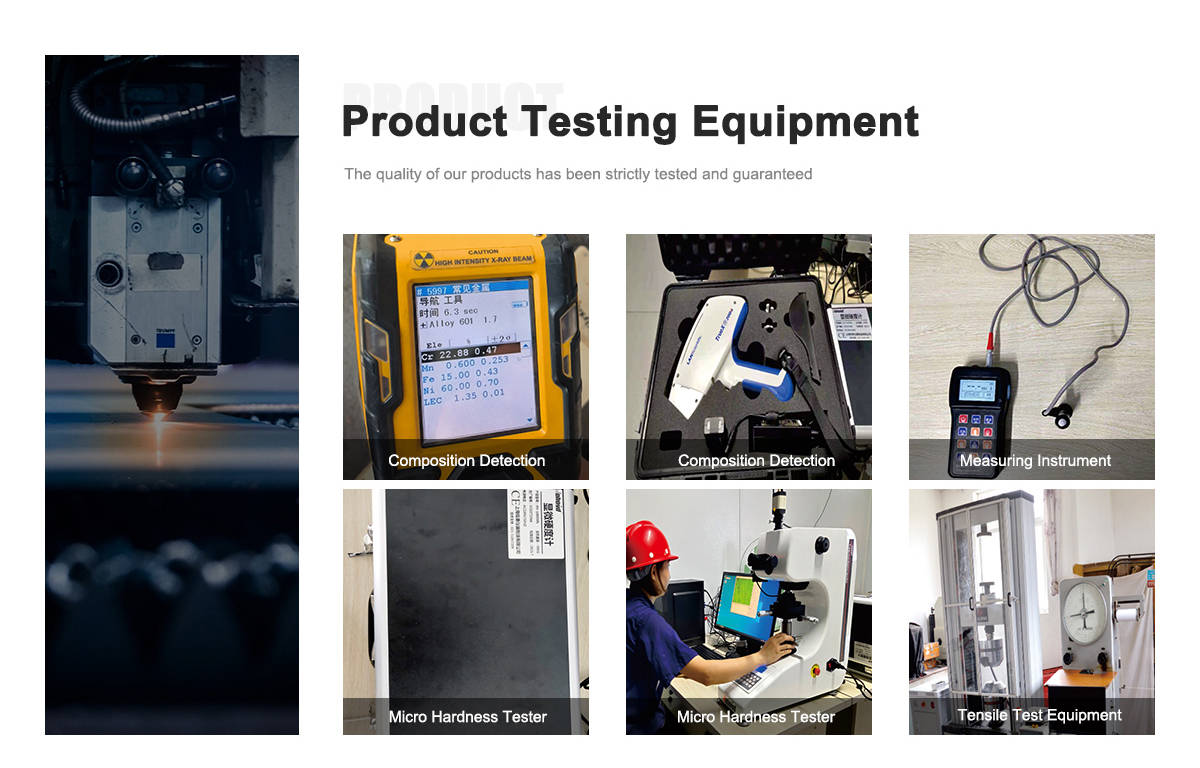

Quality Inspection:

Testing the quality of Inconel pipes is a key step in ensuring that they comply with relevant standards and requirements. The following are some common Inconel pipe quality inspection methods:

Chemical composition analysis: Through chemical composition analysis, it can be determined whether the content of various elements in the Inconel tube meets the standard requirements. Commonly used methods include spectral analysis (such as photoelectric emission spectrometry, spectrophotometry) and chemical analysis (such as wet chemical analysis, inductively coupled plasma emission spectrometry).

Physical Property Testing: Physical property testing is used to evaluate the mechanical properties of Inconel pipes. Common tests include tensile testing, bending testing, impact testing and hardness testing. These tests determine whether the pipe's strength, ductility, toughness and hardness meet requirements.

Dimensional inspection: Dimensional inspection is used to verify that the geometric dimensions of Inconel pipes comply with specifications. By using measuring tools, such as calipers, outer diameter gauges, inner diameter gauges, projectors, etc., parameters such as the outer diameter, wall thickness, inner diameter, length and straightness of the pipe can be measured.

Surface quality assessment: Surface quality assessment is used to check whether the surface of Inconel pipe is smooth, free of cracks, oxides and other defects. Common methods include visual inspection, microscope observation, surface roughness measurement and coating inspection.

Corrosion performance testing: Inconel alloys generally have excellent corrosion resistance. Corrosion performance testing is used to evaluate the corrosion resistance of Inconel pipes in different corrosive media. Commonly used methods include salt spray test, acid corrosion test, alkali corrosion test and electrochemical corrosion test.

Destructive testing: Destructive testing is used to evaluate the performance of Inconel pipes under extreme conditions. Common destructive tests include load-bearing capacity testing, fracture toughness testing and fatigue life testing.

Q&A:

What are the applications of Inconel tubes in the aerospace industry?

Inconel pipes are used in high-temperature components such as aircraft engines, gas turbines, and jet propulsion systems.

What are the applications of Inconel tubes in the chemical industry?

Inconel pipes are widely used in chemical production equipment, reactors and evaporators to cope with the corrosion and high temperature requirements of acidic and alkaline media.

What are the applications of Inconel tubes in the nuclear industry?

Inconel pipes perform key structural and piping functions in nuclear reactors and are resistant to radiation and high temperature corrosion.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China