0

0

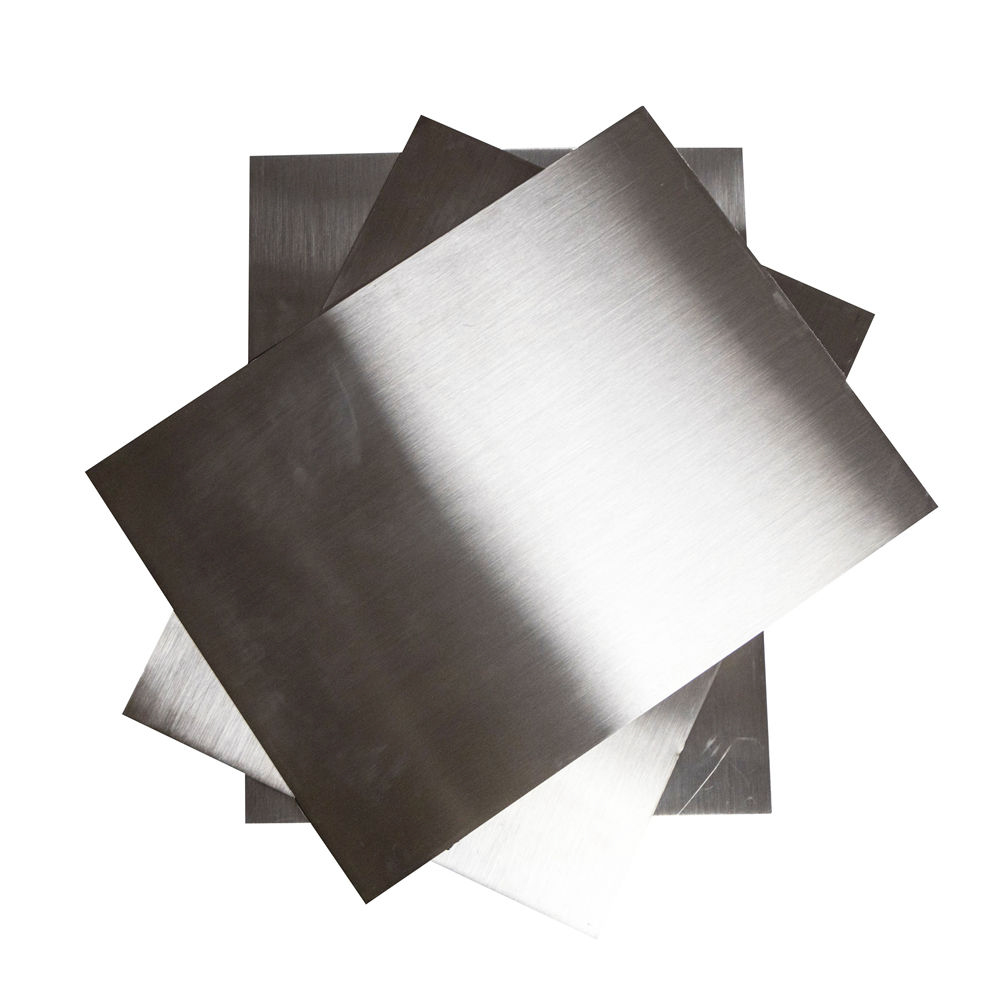

Products Description

Inconel sheets play an important role in the oil and gas industry. Due to its excellent corrosion resistance and high temperature stability, Inconel sheets are widely used in oil and gas extraction, processing and transportation.

In the oil and gas industry, Inconel sheet is commonly used to manufacture key components such as wellbore equipment, well casing, pipe connections and valves. These components are exposed to extreme working conditions such as high temperature, high pressure and corrosive media. With its excellent corrosion resistance, Inconel sheets can resist the erosion of hydrogen sulfide, acid gas, salt water and other corrosive media, ensuring the reliable operation of oil and gas industry equipment.

Parameter:

Item | 600 | 601 | 617 | 625 | 690 | 718 | X750 | 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤1.0 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | ≤5.0 | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | ≤0.015 | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | -- | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | Bal | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤1.0 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.4 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤0.4 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 20-23 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 3.15-4.15 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 8-10 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

SPECIFICATIONS | |

Form | ASTM |

Rod, bar and wire | B 166 |

Plate, sheet and strip | B 168, B 906 |

Seamless pipe and tube | B 167, B 829 |

Welded pipe | B 517, B775 |

Fitting | B 366 |

Billet and bar for reforging | B 472 |

Forging | B 564 |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Feature:

Corrosion Resistance: Inconel sheets are able to withstand corrosive media found in the oil and gas industry, such as acidic and salty environments, to protect the integrity of equipment and pipelines.

High temperature stability: Inconel sheets have excellent high temperature stability and can maintain mechanical properties and corrosion resistance under high temperature conditions.

Resistance to hydrogen embrittlement: Inconel sheets have high resistance to hydrogen embrittlement and can avoid the problem of hydrogen embrittlement cracking in the oil and gas industry.

Strength and Reliability: Inconel sheets offer superior strength and reliability, allowing them to withstand the high stress and pressure loads found in the oil and gas industry.

Application areas:

Petroleum Refining: Inconel sheets are often used to manufacture corrosion-resistant equipment in refineries, such as distillation columns, heat exchangers and reactors, to handle corrosive media and high-temperature conditions.

Oil Well Services: Inconel sheets are used to manufacture oil well casing and tools to resist corrosion and high temperature environments found in oil wells.

Natural Gas Transmission: Inconel sheets are used in the manufacture of natural gas transmission pipelines to protect them from corrosion and high temperature environments.

Q&A:

What are the main advantages of Inconel sheets in the oil and gas industry?

The main advantages of Inconel sheet in the oil and gas industry are its excellent corrosion resistance and high temperature stability. It can withstand corrosive media, high temperatures and pressure, ensuring the reliability and safe operation of equipment and pipelines in harsh environments.

What are the specific applications of Inconel sheets in petroleum refining?

Inconel sheets are commonly used in petroleum refining to manufacture corrosion-resistant equipment such as distillation columns, heat exchangers and reactors. These equipment need to work in corrosive media and high temperature conditions, and Inconel sheets can provide reliable protection and performance.

What is the role of Inconel sheets in natural gas transportation?

In natural gas transmission, Inconel sheets are widely used to manufacture pipelines.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China