0

0

Products Description

Inconel plate is a high temperature resistant alloy plate with excellent heat resistance. It is mainly composed of elements such as nickel, chromium and iron, and also contains other alloying elements such as molybdenum, aluminum and titanium. Inconel board can maintain stable performance in extreme high temperature environments and has excellent heat resistance and high temperature strength. It can withstand the challenges of high-temperature oxidation, hot corrosion and thermal stress, so it is widely used in fields that require working under high-temperature conditions. Whether in the aerospace, energy industry or chemical industry, Inconel board is a reliable material choice that provides stable performance and long service life in extreme high-temperature environments.

Parameter:

Item | 600 | 601 | 617 | 625 | 690 | 718 | X750 | 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤1.0 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | ≤5.0 | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | ≤0.015 | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | -- | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | Bal | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤1.0 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.4 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤0.4 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 20-23 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 3.15-4.15 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 8-10 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

SPECIFICATIONS | |

Form | ASTM |

Rod, bar and wire | B 166 |

Plate, sheet and strip | B 168, B 906 |

Seamless pipe and tube | B 167, B 829 |

Welded pipe | B 517, B775 |

Fitting | B 366 |

Billet and bar for reforging | B 472 |

Forging | B 564 |

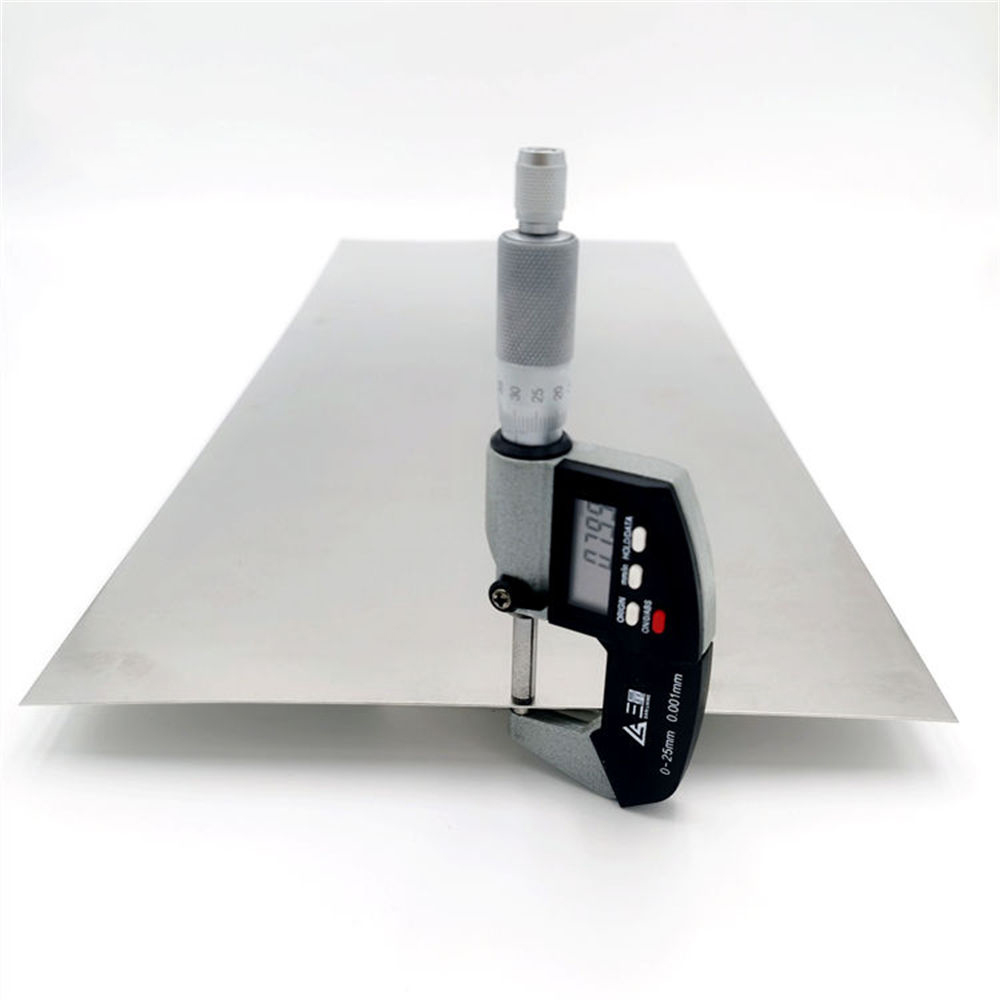

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

High temperature resistance:

High temperature stability: Inconel boards can maintain stable performance under extreme high temperature conditions without significant deformation, creep or thermal fatigue. It is able to withstand prolonged exposure to high temperatures without losing its mechanical strength and structural integrity.

Anti-oxidation performance: Inconel board has excellent anti-oxidation performance and can form a stable oxidation film in high temperature environments to prevent further oxidation reactions. This makes it resistant to oxidation, corrosion and ablation in high temperature atmospheres.

High temperature strength: Inconel board can still maintain high strength and hardness under high temperature conditions without significant plastic deformation or loss of structural integrity. This allows it to withstand mechanical stresses and loads at high temperatures.

Thermal fatigue resistance: Inconel plate has good thermal fatigue resistance and can maintain stable performance under high temperature cyclic loading conditions. It prevents damage caused by thermal expansion and contraction, extending the material's service life.

Influencing factors:

Alloy composition: Inconel plates are made of nickel-based alloy, with added alloy elements such as chromium, molybdenum, iron, and aluminum. The presence of these alloying elements gives Inconel plate good high-temperature stability and oxidation resistance. Nickel has good high-temperature resistance, and the addition of other alloying elements further enhances the material's high-temperature properties.

Oxide film formation: When the Inconel board is exposed to high temperature, a stable oxide film will form on its surface. This oxide film provides an additional layer of protection against further oxidation reactions. This helps slow down the oxidation rate and ablation rate of the material and improves high temperature resistance.

Crystal structure stability: The crystal structure of Inconel plates remains stable under high temperature conditions. Even at high temperatures, its crystal structure does not change significantly, thus maintaining the material's mechanical properties and structural integrity.

Metallurgical Treatment: Inconel plates undergo a special metallurgical treatment and heat treatment process to optimize their high temperature performance. These treatments can improve the material's grain boundary strength, grain size distribution and phase transition behavior, thereby improving its high temperature resistance.

Q&A:

What is Inconel sheet?

Inconel plate is a high-temperature alloy plate composed of nickel, chromium and other alloying elements, which has good corrosion resistance and high temperature stability.

What are the main properties of Inconel sheets?

Inconel sheets have properties such as corrosion resistance, high temperature stability, high strength, good processability and radiation resistance.

What fields are Inconel sheets suitable for?

Inconel sheets are widely used in aerospace, petrochemical, nuclear industry, chemical industry, medical equipment and other fields, especially in high temperature, corrosive and radiation environments.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China