0

0

Products Description

Inconel sheets play an important role in the nuclear industry. Due to its excellent corrosion resistance, high temperature stability and radiation resistance, Inconel sheets are widely used in nuclear power plants, nuclear reactors and other nuclear industry facilities.

In the nuclear industry, Inconel sheets are commonly used to manufacture key components of nuclear reactors, such as fuel elements, reactor pressure vessels and heat exchangers. These components work in high temperature, high pressure and radiation environments, which place extremely high requirements on material performance. Inconel sheets can maintain their strength and stability in high temperature and radiation environments, and at the same time have excellent corrosion resistance. They can resist the erosion of corrosive media and radioactive materials produced in nuclear reactors, ensuring the safe operation of nuclear reactors.

Parameter:

Item | 600 | 601 | 617 | 625 | 690 | 718 | X750 | 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤1.0 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | ≤5.0 | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | ≤0.015 | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | -- | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | Bal | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤1.0 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.4 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤0.4 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 20-23 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 3.15-4.15 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 8-10 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

SPECIFICATIONS | |

Form | ASTM |

Rod, bar and wire | B 166 |

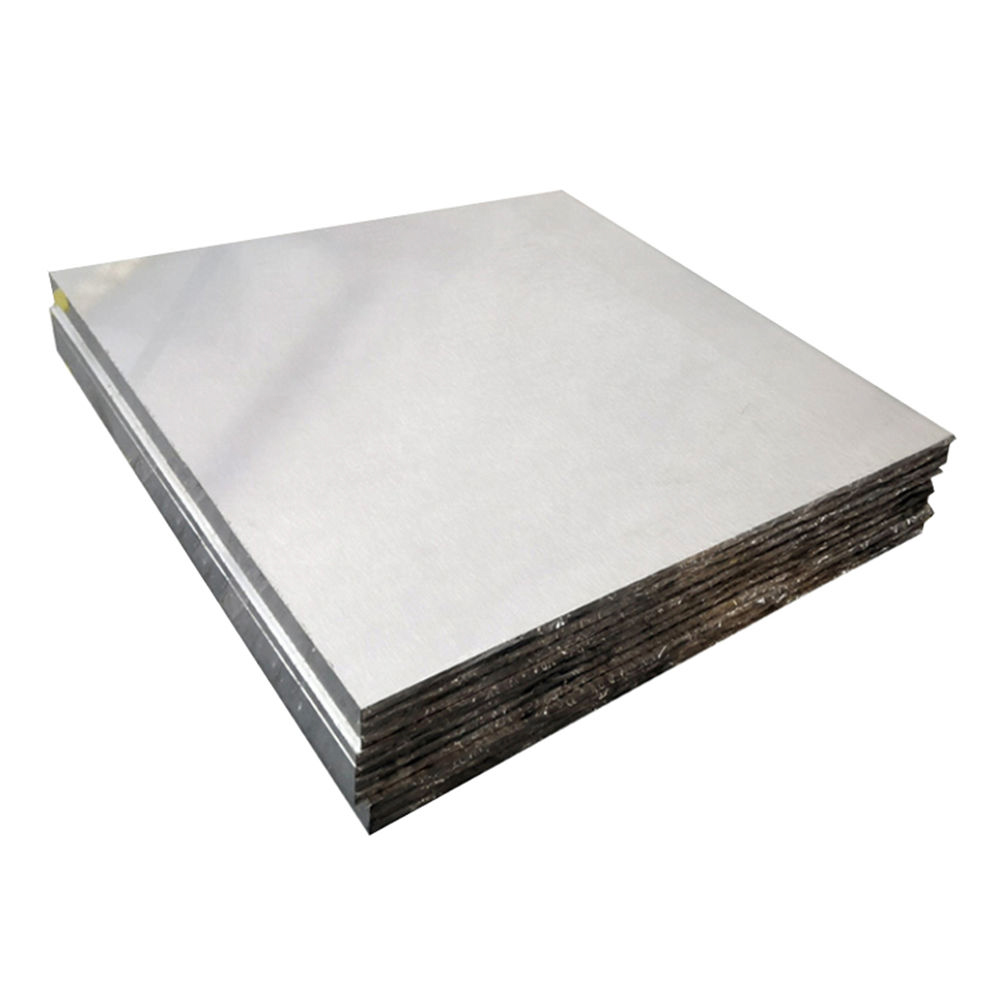

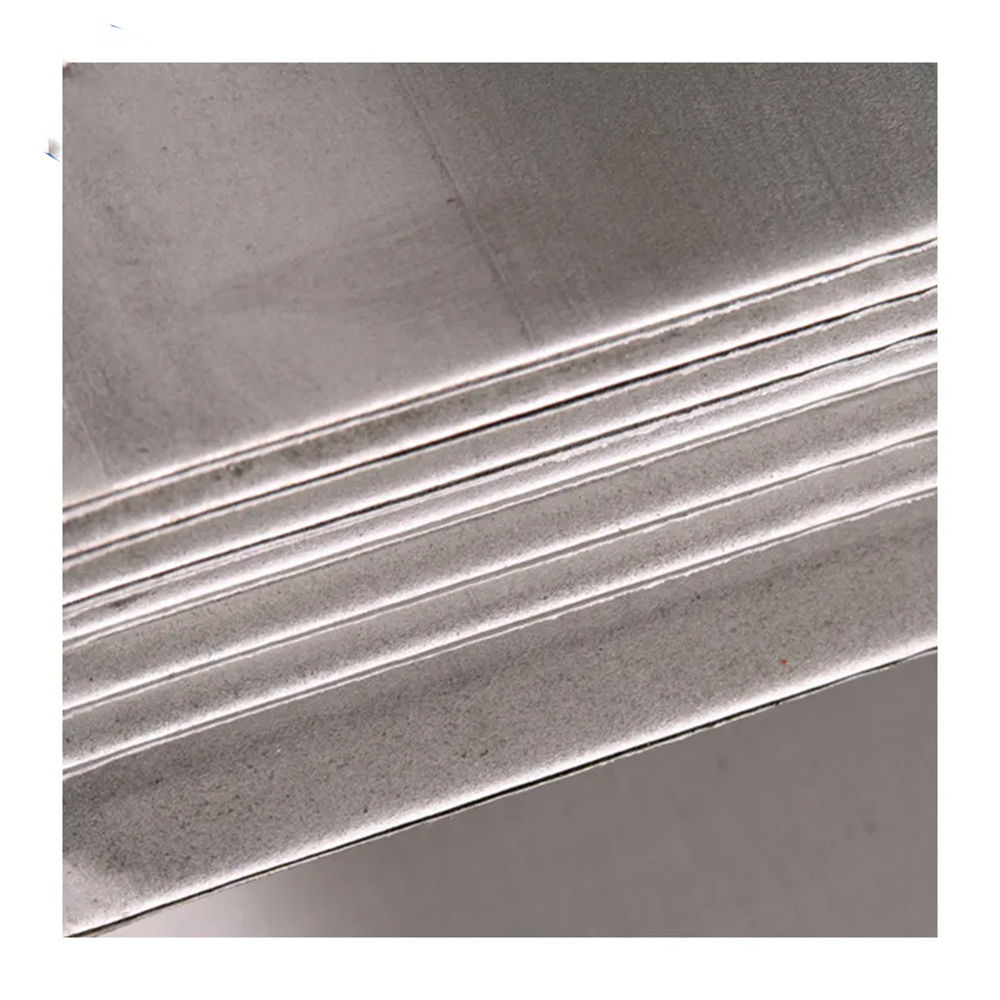

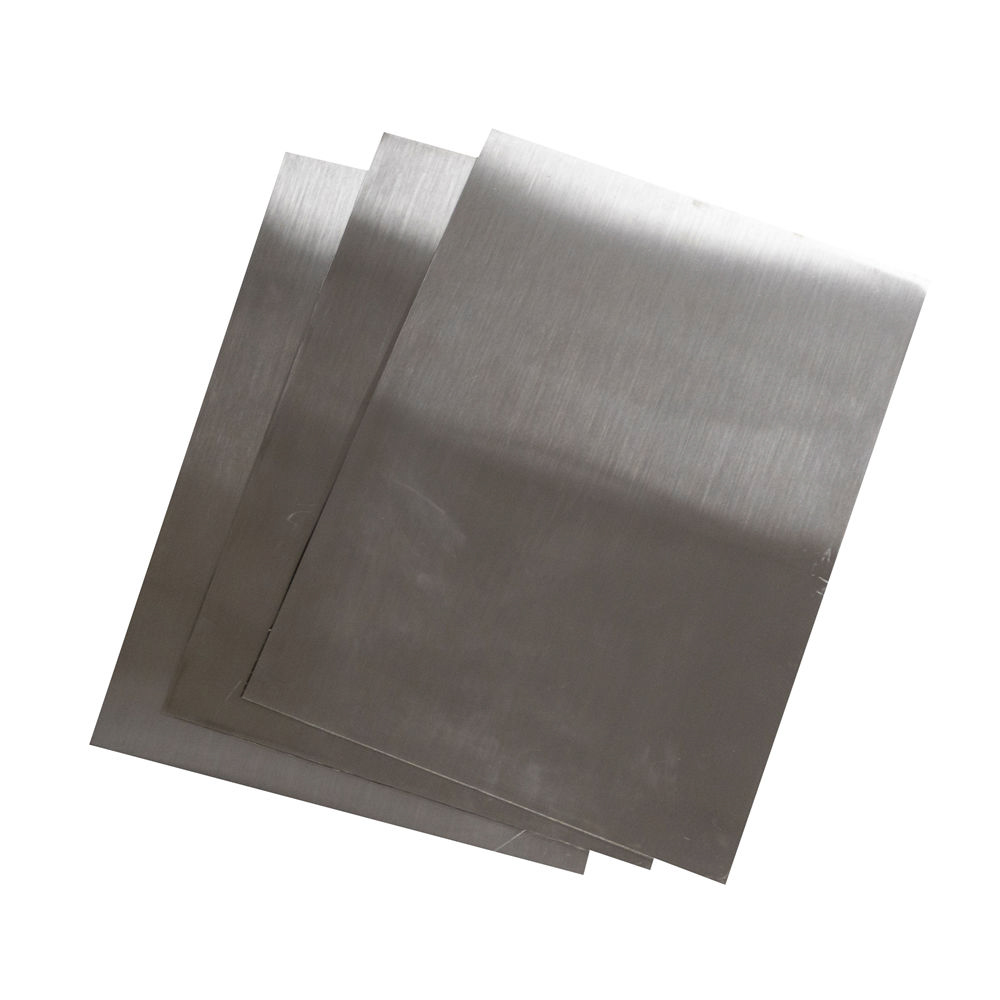

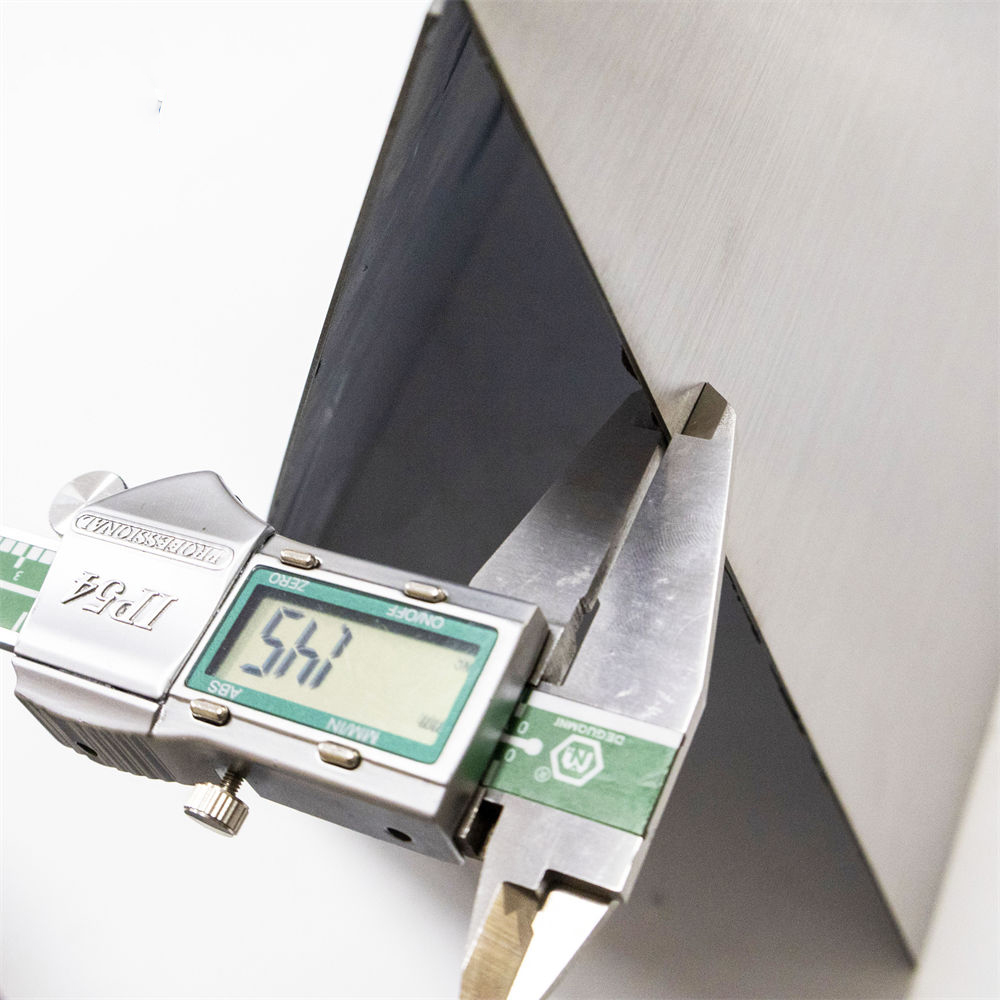

Plate, sheet and strip | B 168, B 906 |

Seamless pipe and tube | B 167, B 829 |

Welded pipe | B 517, B775 |

Fitting | B 366 |

Billet and bar for reforging | B 472 |

Forging | B 564 |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Feature:

Corrosion resistance: Inconel sheets have excellent corrosion resistance and can withstand corrosive media in the nuclear industry, such as acidic and high-temperature environments.

High temperature stability: Inconel panels can maintain stability under high temperature conditions and have good fire resistance and oxidation resistance.

Strength and Reliability: Inconel sheets have high strength and reliability and are able to withstand the high stress and pressure loads found in the nuclear industry.

Radiation Resistance: Inconel sheets have good radiation resistance and are able to withstand radiation environments in the nuclear industry and maintain their performance and structural integrity.

Application areas:

Nuclear Reactors: Inconel sheets are widely used in key components and structures of nuclear reactors, such as fuel cladding, reactor pressure vessels and control rods. It provides reliable performance and durability in high temperature, high pressure and radiation environments.

Nuclear fuel cycle facilities: The applications of Inconel sheets in nuclear fuel cycle facilities include manufacturing enrichment equipment, extraction equipment and storage containers. These devices require resistance to corrosion, high temperatures and radiation, and Inconel sheets meet these requirements.

Nuclear waste processing: Inconel sheets are used in corrosion-resistant containers, pipes and fittings in nuclear waste processing facilities. It can withstand the erosion of nuclear waste and the impact of high-temperature environments, ensuring the safe and reliable operation of facilities.

Q&A:

What are the advantages of Inconel sheets in the nuclear industry?

The advantages of Inconel sheets in the nuclear industry are mainly reflected in their corrosion resistance, high temperature stability and radiation resistance. This makes it an ideal material for corrosion, temperature and radiation resistance requirements in nuclear facilities.

What are the specific applications of Inconel sheets in nuclear reactors?

Specific applications of Inconel sheets in nuclear reactors include the manufacture of key components such as fuel cladding, reactor pressure vessels and control rods. These components need to work in high temperature, high pressure and radiation environments, and the high temperature stability, corrosion resistance and radiation resistance of Inconel sheets can meet these requirements.

Why are Inconel sheets used in nuclear waste disposal?

Inconel sheets are used in nuclear waste disposal because of their excellent corrosion resistance and high temperature stability. Nuclear waste treatment facilities need to resist the erosion of nuclear waste and withstand high temperature environments, and Inconel sheets can provide reliable durability and protect the safe operation of facilities.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China