0

0

Products Description

Hastelloy alloy rods are widely used in the field of semiconductor materials. The semiconductor industry has very stringent requirements for materials, requiring high-temperature stability, corrosion resistance, and excellent mechanical properties. Hastelloy alloy rods precisely meet these requirements, making them an ideal choice in semiconductor manufacturing.

First, Hastelloy alloy rods have excellent corrosion resistance and are resistant to acids, alkalis and other corrosive chemicals used in the semiconductor manufacturing process. This is very important to protect critical components in semiconductor equipment and processing processes, ensuring long-term stable operation and good performance of the equipment.

Secondly, Hastelloy alloy rod has excellent high temperature stability. In semiconductor production, many steps need to be performed in high-temperature environments, so materials are required that can maintain their mechanical properties and corrosion resistance under high-temperature conditions. Hastelloy alloy rods are able to withstand the challenges of high temperature applications, ensuring equipment reliability and stability.

In addition, Hastelloy alloy rods also have good mechanical properties such as strength and toughness. This makes it more capable of withstanding various forces and stresses during the semiconductor manufacturing process and maintains its original shape and performance without being easily deformed or damaged.

Among semiconductor materials, Hastelloy alloy rods are often used to manufacture corrosive gas delivery pipes, heater elements, reaction chambers and components of vacuum systems, etc. Its excellent corrosion resistance, high temperature stability and mechanical properties enable it to meet the stringent requirements of the semiconductor manufacturing process without negatively affecting the quality and performance of the final product.

In short, Hastelloy alloy rods have important application value in the field of semiconductor materials. Its corrosion resistance, high temperature stability and excellent mechanical properties make it an ideal choice in semiconductor manufacturing, ensuring equipment reliability, stability and high-quality product manufacturing.

Product Information

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.00-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | Customized |

Plate | Customized |

Hastelloy grades: Hastelloy C276, Hastelloy C22, Hastelloy C-2000, Hastelloy C-4, Hastelloy C, Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy X, Hastelloy G-30, Hastelloy G-35, etc.

UNS N10276, UNS N06022, UNS N06200, UNS N10665, UNS N10675, UNS N06030, UNS N06002, etc. Hastelloy seamless pipes, steel plates, round bars, forgings, flanges, H-rings, welded pipes, steel strips, straight bars, wires and supporting welding consumables, processed parts, etc.

Hastelloy | |||||||||||

Grade | Ni | Cr | Mo | W | Co | C | Mn | Si | S | P | Other |

C-276 | Rem | 15-16.5 | 15-17 | 3-4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.001 | 0.015 | V0.1-0.3 |

C-22 | 56-59 | 20-22.5 | 12.5-14.5 | 2.5-3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.02 | V0.35 | |

C-2000 | Rem | 22-24 | 15-17 | 2 | 0.01 | 0.5 | 0.06 | 0.01 | 0.025 | A10.5 Cul.6 | |

B-2 | Rem | 0.4-0.7 | 26-30 | 1 | 0.01 | 1 | 0.08 | 0.01 | 0.02 | Cu0.5 | |

B-3 | 65 | 1-3 | 27-32 | 3 | 3 | 0.01 | 3 | 0.1 | 0.01 | 0.03 | Vo.2 A10.5 Ti0.2 Cuo.2 |

G-30 | Rem | 28-31.5 | 4-6 | 1.5-4 | ≤5 | 0.03 | ≤2 | ≤1 | ≤0.02 | ≤0.04 | Nb/Ta0.3-1.5 Cul-2.4 |

X | Rem | 20.5-23.5 | 8-10 | 0.2-1 | 0.5-2.5 | 0.05-0.15 | 1 | 1 | 0.015 | 0.025 | A10.5 Ti0.15 B0.005 |

C-4 | Rem | 14-18 | 14-17 | 2 | 0.015 | 1 | 0.08 | 0.7 | 0.04 | Ti0.7 | |

G-35 | 8-10 | 5 | 2 | 0.03 | 2-3 | 1.5 | 1 | 2 | 0.02 | Cu0.04 | |

C | Rem | 14.5-17.5 | 15-17 | 3-4.5 | 0.03 | 1 | 0.03 | 0.04 | |||

Hastelloy | Density (g/cm3) | Melting point (℃) | Elongation A5 (%) | Tensile Strength (Rm N/mm2) | Yield Strength (RP0.2N/mm2) |

C-276 | 8.9 | 1325-1370℃ | 62 | 758 | 363 |

C-22 | 8.9 | 1325-1370 ℃ | 40 | 690 | 283 |

C-2000 | 8.5 | 1399℃ 2550°F | 45 | 690 | 283 |

B-2 | 9.2 | 1330-1380℃ | 40 | 745 | 325 |

B-3 | 9.22 | 1370-1418℃ | 40 | 760 | 350 |

G-30 | 8.22 | 1399℃ 2550°F | 62 | 524 | 200 |

X | 8.3 | 1260-1355℃ | 30 | 690 | / |

C-4 | 8.64 | 399°C 2550°F | 40 | 690 | 280 |

G-35 | 8.22 | 1370-1400℃ | / | / | / |

C | 8.94 | 1330-1380 ℃ | 40 | 690 | 310 |

For more details, pls directly contact us.

Characteristic:

High-temperature stability: Hastelloy alloy rods have excellent high-temperature stability and can maintain the stability of their structure and properties during high-temperature processing of semiconductor materials.

Corrosion resistance: Hastelloy alloy rods have excellent corrosion resistance to the corrosive media used in semiconductor manufacturing, protecting equipment and materials from corrosion damage.

Low Magnetism: Hastelloy alloy rods generally have low magnetism and are suitable for use in semiconductor manufacturing processes that are sensitive to magnetism.

Excellent mechanical properties: Hastelloy alloy rods have good mechanical strength and toughness and can withstand mechanical stress and deformation during the semiconductor manufacturing process.

Advantage:

High-temperature performance: Hastelloy alloy rods perform well in high-temperature environments and can meet the high-temperature stability requirements in the semiconductor manufacturing process, such as annealing and heat treatment.

Corrosion resistance: The corrosion resistance of Hastelloy alloy rods makes it an ideal choice for resisting corrosive media in semiconductor materials, protecting equipment and materials from corrosion.

Low pollution: Hastelloy alloy rods have low pollution and will not introduce additional impurities into semiconductor materials, ensuring the purity and quality stability of semiconductor products.

Specific applications in semiconductor materials:

Corrosive media treatment: Hastelloy alloy rods can be used to manufacture components in semiconductor equipment that handle corrosive media, such as pickling tanks, wet cleaning equipment, etc., to protect equipment from corrosion.

Heat treatment equipment: Hastelloy alloy rods can be used to manufacture heat treatment equipment for semiconductor materials, such as heat treatment furnaces and annealing furnaces, to provide a high-temperature and stable environment.

Corrosion protection: Hastelloy alloy rods can be used to manufacture equipment such as pipes, valves and pumps involving corrosive media to prevent corrosion damage to semiconductor materials.

Packaging materials: Hastelloy alloy rods can be used to manufacture semiconductor device packaging materials, providing good corrosion resistance and high temperature stability to protect devices from the external environment.

Other applications in semiconductor production processes: Hastelloy alloy rods can also be used to manufacture other equipment and components in semiconductor production processes, such as reactors, furnace tubes, transmission systems, etc., to meet the requirements under high temperature, high pressure and corrosive conditions.

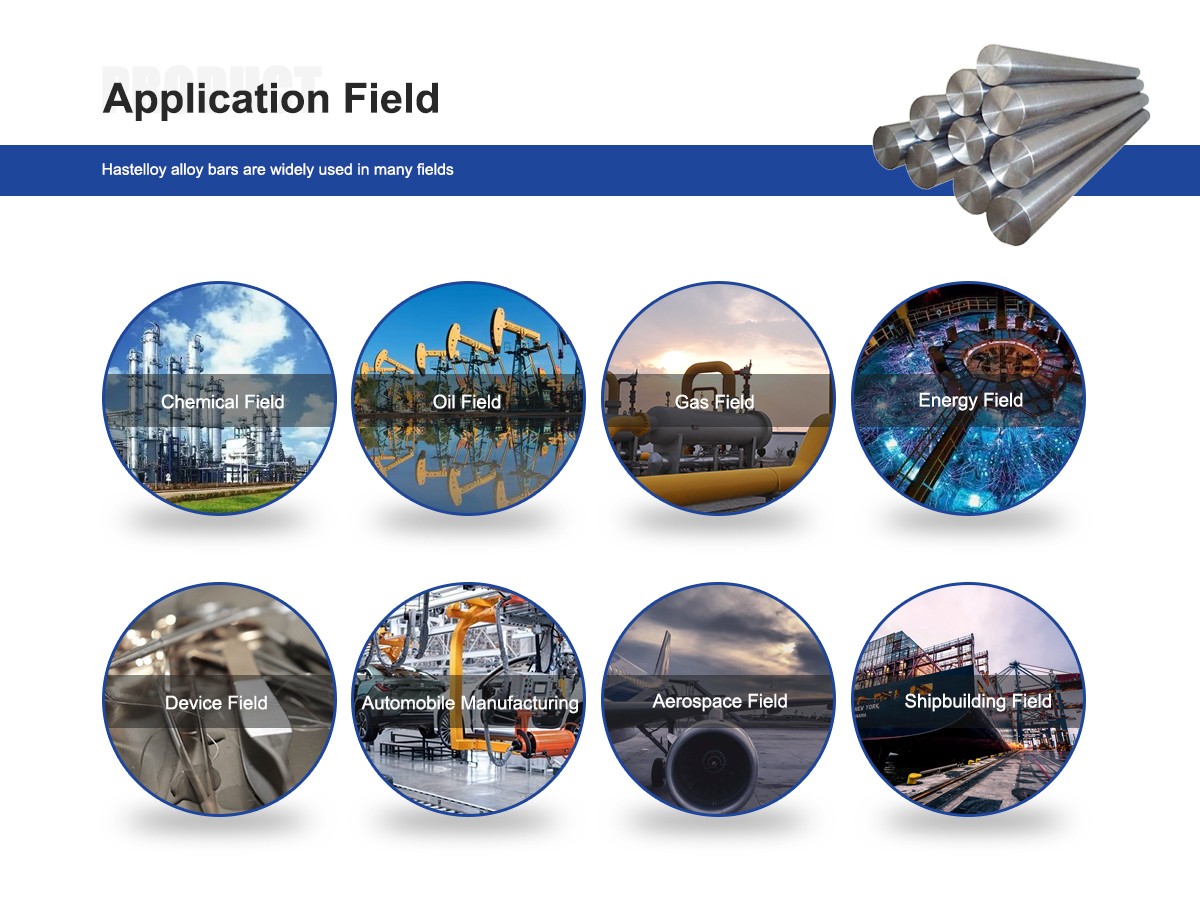

Common application areas:

Petroleum and chemical industry: Hastelloy alloy rods are widely used in the petroleum and chemical industry to manufacture corrosion-resistant equipment and pipelines, such as corrosive media storage tanks, reactors, heat exchangers and piping systems. It can resist the erosion of strong acid, strong alkali and high temperature environment, ensuring the safe operation and long life of the equipment.

Aerospace industry: Hastelloy alloy rods are widely used in the aerospace field to manufacture components and equipment under high temperatures, high pressures and corrosive environments, such as jet engine components, combustion chambers, gas turbines and chemical reactors.

Chemical Industry: Due to its excellent corrosion resistance, Hastelloy alloy rods are commonly used in the chemical industry to manufacture chemical reactors, distillation columns, storage tanks and piping systems. It can resist the erosion of various corrosive chemicals and ensure the stability and safety of chemical equipment.

Food processing industry: In the food processing industry, Hastelloy alloy rods are often used to manufacture equipment and containers that come into contact with food, such as food warmers, mixers and storage tanks. Its hygienic properties and corrosion resistance make it an ideal material for handling food and beverages.

Energy industry: Hastelloy alloy rods are widely used in nuclear energy equipment, solar thermal power generation systems, oil and gas extraction equipment, etc. in the energy field. Its corrosion resistance and high temperature stability enable it to adapt to harsh working environments and ensure the reliability and safety of energy equipment.

In general, Hastelloy alloy rods are widely used in many application fields due to their excellent corrosion resistance, high temperature stability and excellent mechanical properties. Whether in industrial manufacturing, energy fields or food processing industries, Hastelloy alloy rods can provide reliable and high-quality solutions.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China