0

0

Products Description

Hastelloy alloy rods play an important role in turbine engines. As a high-performance alloy material, Hastelloy alloy rods can meet the stringent requirements of turbine engines for high temperature, high pressure and corrosive environments, ensuring engine reliability and performance.

Turbine engines are a critical power plant used in aircraft, marine and industrial applications. In turbine engines, high temperatures and high-velocity airflows exert tremendous pressure and thermal loads on key components, and Hastelloy alloy rods are able to withstand these extreme conditions due to their excellent performance.

Hastelloy alloy rod has excellent high temperature resistance and can maintain the stability and strength of its structure in high temperature environments. It can resist the erosion of engine components such as turbine blades, combustion chamber components and nozzles by high-temperature airflow, high-temperature combustion products and hot corrosive media.

In addition, Hastelloy alloy rods also have excellent thermal fatigue resistance. In turbine engines, components often face thermal shock from high-temperature cycles and rapid temperature changes, and Hastelloy alloy rods can withstand such thermal stress and fatigue, extending the service life of components.

Hastelloy alloy rods also have excellent corrosion resistance and can resist the erosion of engine parts by acidic combustion products and corrosive media. This makes Hastelloy alloy rod an ideal material for manufacturing corrosion-resistant components in turbine engines.

Product Information

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.00-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | Customized |

Plate | Customized |

Hastelloy grades: Hastelloy C276, Hastelloy C22, Hastelloy C-2000, Hastelloy C-4, Hastelloy C, Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy X, Hastelloy G-30, Hastelloy G-35, etc.

UNS N10276, UNS N06022, UNS N06200, UNS N10665, UNS N10675, UNS N06030, UNS N06002, etc. Hastelloy seamless pipes, steel plates, round bars, forgings, flanges, H-rings, welded pipes, steel strips, straight bars, wires and supporting welding consumables, processed parts, etc.

Hastelloy | |||||||||||

Grade | Ni | Cr | Mo | W | Co | C | Mn | Si | S | P | Other |

C-276 | Rem | 15-16.5 | 15-17 | 3-4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.001 | 0.015 | V0.1-0.3 |

C-22 | 56-59 | 20-22.5 | 12.5-14.5 | 2.5-3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.02 | V0.35 | |

C-2000 | Rem | 22-24 | 15-17 | 2 | 0.01 | 0.5 | 0.06 | 0.01 | 0.025 | A10.5 Cul.6 | |

B-2 | Rem | 0.4-0.7 | 26-30 | 1 | 0.01 | 1 | 0.08 | 0.01 | 0.02 | Cu0.5 | |

B-3 | 65 | 1-3 | 27-32 | 3 | 3 | 0.01 | 3 | 0.1 | 0.01 | 0.03 | Vo.2 A10.5 Ti0.2 Cuo.2 |

G-30 | Rem | 28-31.5 | 4-6 | 1.5-4 | ≤5 | 0.03 | ≤2 | ≤1 | ≤0.02 | ≤0.04 | Nb/Ta0.3-1.5 Cul-2.4 |

X | Rem | 20.5-23.5 | 8-10 | 0.2-1 | 0.5-2.5 | 0.05-0.15 | 1 | 1 | 0.015 | 0.025 | A10.5 Ti0.15 B0.005 |

C-4 | Rem | 14-18 | 14-17 | 2 | 0.015 | 1 | 0.08 | 0.7 | 0.04 | Ti0.7 | |

G-35 | 8-10 | 5 | 2 | 0.03 | 2-3 | 1.5 | 1 | 2 | 0.02 | Cu0.04 | |

C | Rem | 14.5-17.5 | 15-17 | 3-4.5 | 0.03 | 1 | 0.03 | 0.04 | |||

Hastelloy | Density (g/cm3) | Melting point (℃) | Elongation A5 (%) | Tensile Strength (Rm N/mm2) | Yield Strength (RP0.2N/mm2) |

C-276 | 8.9 | 1325-1370℃ | 62 | 758 | 363 |

C-22 | 8.9 | 1325-1370 ℃ | 40 | 690 | 283 |

C-2000 | 8.5 | 1399℃ 2550°F | 45 | 690 | 283 |

B-2 | 9.2 | 1330-1380℃ | 40 | 745 | 325 |

B-3 | 9.22 | 1370-1418℃ | 40 | 760 | 350 |

G-30 | 8.22 | 1399℃ 2550°F | 62 | 524 | 200 |

X | 8.3 | 1260-1355℃ | 30 | 690 | / |

C-4 | 8.64 | 399°C 2550°F | 40 | 690 | 280 |

G-35 | 8.22 | 1370-1400℃ | / | / | / |

C | 8.94 | 1330-1380 ℃ | 40 | 690 | 310 |

For more details, pls directly contact us.

Characteristic:

High temperature resistance: Hastelloy alloy rods maintain good strength and stability in high temperature environments and are suitable for high temperature components of turbine engines.

Corrosion Resistance: Hastelloy alloy rods have excellent resistance to corrosion in acidic and alkaline environments, extending the service life of turbine engines.

Oxidation Resistance: Hastelloy alloy rods resist oxidation and high temperature corrosion, providing excellent performance and reliability.

Low thermal expansion coefficient: Hastelloy alloy rod has a low thermal expansion coefficient, which helps maintain dimensional stability in high temperature environments.

Advantage:

High-temperature strength: Hastelloy alloy rods maintain excellent strength and tensile properties at high temperatures and are suitable for the manufacture of high-temperature components for turbine engines.

Corrosion Resistance: The corrosion resistance of Hastelloy alloy rods makes it ideal for resisting the attack of acidic and alkaline gases in turbine engines.

Reliability: The stability and reliability of Hastelloy alloy rods ensure that turbine engines operate stably for a long time in harsh working environments.

Antioxidant properties:

Hastelloy alloy rods are known for their excellent oxidation resistance. Oxidation resistance refers to the ability of a material to resist oxidation in high-temperature environments, and Hastelloy alloy rods can maintain the smoothness of their surfaces and the integrity of their protective layers under extreme high-temperature conditions.

This antioxidant layer is stable at high temperatures and has good adhesion. It can prevent oxygen and high-temperature combustion products from eroding the surface of Hastelloy alloy rods, reduce the oxidation rate, and extend the service life of the material.

The oxidation resistance of Hastelloy alloy rods makes it widely used in high temperature applications, such as aerospace engines, gas turbines, petroleum refining, etc. In these applications, Hastelloy alloy rods are used to manufacture high-temperature components such as combustion chamber components, heat exchanger tubes, high-temperature furnace internals, etc. It can resist oxidation and thermal corrosion in high-temperature atmospheres, maintaining the smoothness of the component surface and the integrity of the protective layer.

Specific applications in turbine engines:

Combustion chamber parts: Hastelloy alloy rods can be used to manufacture parts such as nozzles, spark plugs and spark plug sleeves in the combustion chamber to resist erosion by high temperatures and corrosive gases.

Turbine blades: Hastelloy alloy rods can be used to manufacture turbine engine blades. They have good high temperature resistance and corrosion resistance, ensuring the reliability and life of the blades in high-temperature working environments.

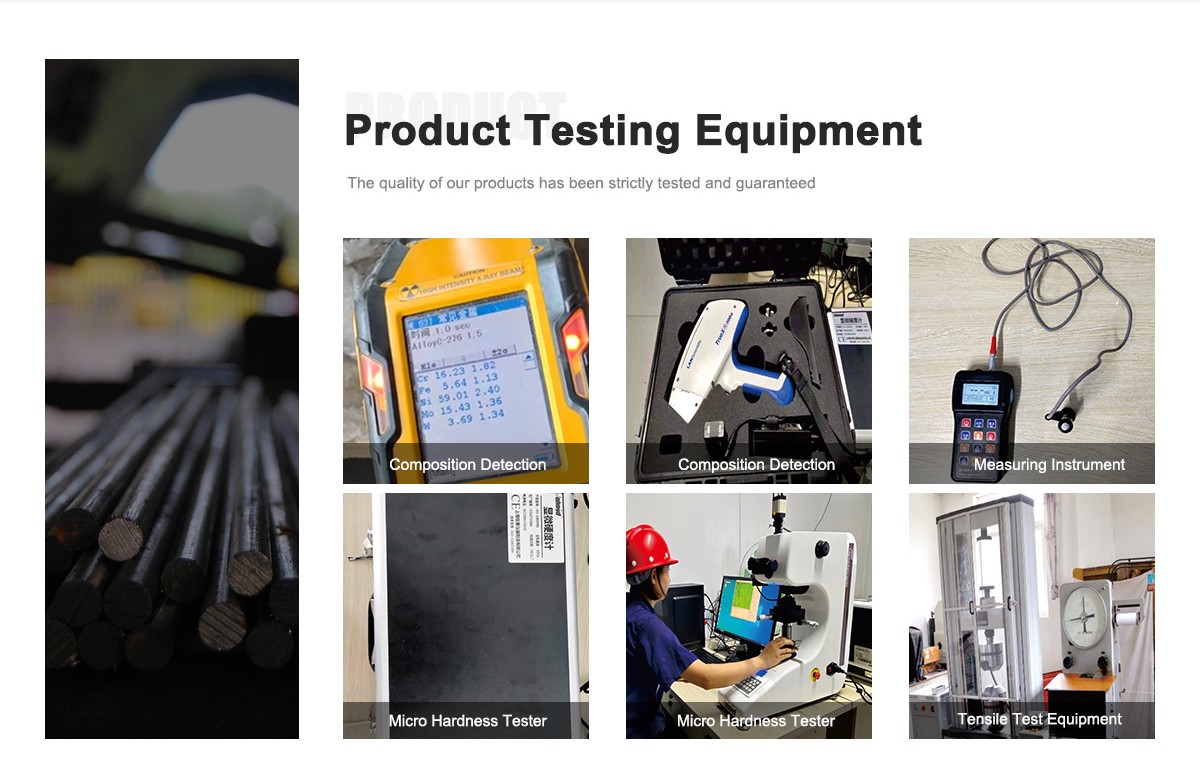

Quality testing methods and standards:

Chemical composition analysis: Through chemical composition analysis, it can be determined whether the content of each element in the Hastelloy alloy rod meets the specified standards. Commonly used chemical analysis methods include spectral analysis, mass spectrometry, inductively coupled plasma emission spectrometry, etc.

Mechanical property testing: Mechanical property testing can evaluate the mechanical properties such as strength, toughness and ductility of Hastelloy alloy rods. Common mechanical property tests include tensile tests, impact tests, hardness tests, etc.

Metallographic microscopic analysis: Metallographic microscopic analysis can observe the microstructure and grain structure of Hastelloy alloy rods, and evaluate the grain size, phase content and uniformity of the material. This analysis typically uses equipment such as metallographic microscopes and scanning electron microscopes.

Corrosion performance test: The corrosion performance test can evaluate the corrosion resistance of Hastelloy alloy rods in different corrosive media. Common corrosion performance tests include acid corrosion test, salt spray corrosion test, high temperature corrosion test, etc.

Dimensional inspection: Dimensional inspection is used to verify whether the length, diameter, roundness and surface finish of Hastelloy alloy rods meet the standards. Commonly used dimensional inspection tools include micrometers, vernier calipers, optical image measurement systems, etc.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China