0

0

Products Description

Hastelloy alloy rod is a high-performance alloy material composed of nickel, molybdenum, chromium and other elements. It has excellent corrosion resistance and high temperature resistance and is widely used in various industrial fields that require high corrosion resistance and heat resistance. Hastelloy alloy rod has excellent acid resistance, alkali resistance, oxidation resistance and corrosion resistance, and can resist the erosion of various corrosive media, including acidic solutions, oxidants and salt water. It also exhibits excellent mechanical properties, with good resistance to stress corrosion cracking and resistance to chloride stress corrosion cracking. Hastelloy alloy rods can be made into products of different shapes and sizes, such as rods, plates, pipes and welding materials, to meet various engineering needs. It is widely used in the fields of chemical industry, petroleum, aerospace, nuclear energy and medicine, and is used to manufacture chemical equipment, oil drilling tools, gas turbine engine parts, etc. Hastelloy alloy rods provide engineers and manufacturers with a sustainable and innovative material choice due to their excellent performance and reliability.

Product Information

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.00-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | Customized |

Plate | Customized |

Hastelloy grades: Hastelloy C276, Hastelloy C22, Hastelloy C-2000, Hastelloy C-4, Hastelloy C, Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy X, Hastelloy G-30, Hastelloy G-35, etc.

UNS N10276, UNS N06022, UNS N06200, UNS N10665, UNS N10675, UNS N06030, UNS N06002, etc. Hastelloy seamless pipes, steel plates, round bars, forgings, flanges, H-rings, welded pipes, steel strips, straight bars, wires and supporting welding consumables, processed parts, etc.

Hastelloy | |||||||||||

Grade | Ni | Cr | Mo | W | Co | C | Mn | Si | S | P | Other |

C-276 | Rem | 15-16.5 | 15-17 | 3-4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.001 | 0.015 | V0.1-0.3 |

C-22 | 56-59 | 20-22.5 | 12.5-14.5 | 2.5-3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.02 | V0.35 | |

C-2000 | Rem | 22-24 | 15-17 | 2 | 0.01 | 0.5 | 0.06 | 0.01 | 0.025 | A10.5 Cul.6 | |

B-2 | Rem | 0.4-0.7 | 26-30 | 1 | 0.01 | 1 | 0.08 | 0.01 | 0.02 | Cu0.5 | |

B-3 | 65 | 1-3 | 27-32 | 3 | 3 | 0.01 | 3 | 0.1 | 0.01 | 0.03 | Vo.2 A10.5 Ti0.2 Cuo.2 |

G-30 | Rem | 28-31.5 | 4-6 | 1.5-4 | ≤5 | 0.03 | ≤2 | ≤1 | ≤0.02 | ≤0.04 | Nb/Ta0.3-1.5 Cul-2.4 |

X | Rem | 20.5-23.5 | 8-10 | 0.2-1 | 0.5-2.5 | 0.05-0.15 | 1 | 1 | 0.015 | 0.025 | A10.5 Ti0.15 B0.005 |

C-4 | Rem | 14-18 | 14-17 | 2 | 0.015 | 1 | 0.08 | 0.7 | 0.04 | Ti0.7 | |

G-35 | 8-10 | 5 | 2 | 0.03 | 2-3 | 1.5 | 1 | 2 | 0.02 | Cu0.04 | |

C | Rem | 14.5-17.5 | 15-17 | 3-4.5 | 0.03 | 1 | 0.03 | 0.04 | |||

Hastelloy | Density (g/cm3) | Melting point (℃) | Elongation A5 (%) | Tensile Strength (Rm N/mm2) | Yield Strength (RP0.2N/mm2) |

C-276 | 8.9 | 1325-1370℃ | 62 | 758 | 363 |

C-22 | 8.9 | 1325-1370 ℃ | 40 | 690 | 283 |

C-2000 | 8.5 | 1399℃ 2550°F | 45 | 690 | 283 |

B-2 | 9.2 | 1330-1380℃ | 40 | 745 | 325 |

B-3 | 9.22 | 1370-1418℃ | 40 | 760 | 350 |

G-30 | 8.22 | 1399℃ 2550°F | 62 | 524 | 200 |

X | 8.3 | 1260-1355℃ | 30 | 690 | / |

C-4 | 8.64 | 399°C 2550°F | 40 | 690 | 280 |

G-35 | 8.22 | 1370-1400℃ | / | / | / |

C | 8.94 | 1330-1380 ℃ | 40 | 690 | 310 |

For more details, pls directly contact us.

Production Process:

Raw material preparation: Select appropriate Hastelloy alloy powder or block as raw material to ensure that its composition meets the specified requirements.

Material pretreatment: Raw materials are pretreated, including cleaning, drying and smelting steps to remove impurities and oxides.

Smelting: Heating pretreated raw materials to high temperatures to melt them into a liquid state. In the molten state, the alloy composition can be adjusted to meet specific requirements.

Pouring: The molten alloy is poured into a rod-shaped mold to form the initial shape of the alloy rod.

Hot processing: The initial shape of the alloy rod is hot processed, including hot rolling, hot drawing, hot extrusion and other processes, to further change its shape and size.

Cold processing: After hot processing, the alloy rod is subjected to cold processing, such as cold drawing, cold rolling and other processes, to improve its mechanical properties and dimensional accuracy.

Heat treatment: Heat treatment is performed on the cold-worked alloy rod, including annealing, solution treatment, aging treatment and other steps to adjust its structure and properties.

Surface treatment: Surface treatments such as polishing and pickling are performed on the heat-treated alloy rods to remove scale and contaminants.

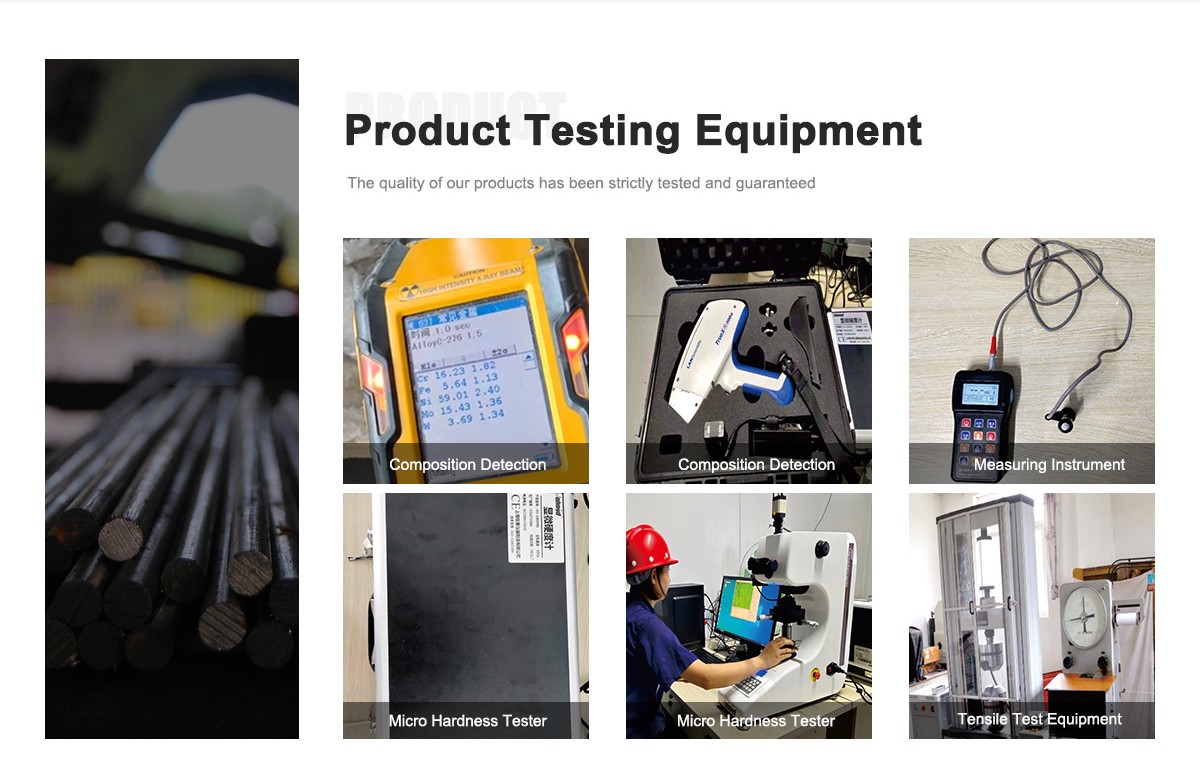

Detection and inspection: Conduct various quality inspections on the produced Hastelloy alloy rods, including chemical composition analysis, dimensional inspection, mechanical property testing, metallographic analysis, corrosion resistance testing, etc.

Packaging and storage: Qualified Hastelloy alloy rods are packaged and stored as required to prevent corrosion and mechanical damage.

Quality inspection method:

Chemical composition analysis: Determine the elemental composition of Hastelloy alloy rod through chemical analysis technology. Commonly used methods include spectral analysis (such as photoelectric emission spectrometry, spectroscopy, etc.) and chemical analysis (such as wet chemical analysis, inductively coupled plasma emission spectrometry, etc.).

Dimensional inspection: Measure and inspect the length, diameter, roundness, surface roughness, etc. of Hastelloy alloy rods. Commonly used tools include calipers, micrometers, microscopes, etc.

Metallographic analysis: Observe and analyze the structure of Hastelloy alloy rods through a metallographic microscope, including grain size, grain boundaries, phase content, etc. Metallographic analysis can help evaluate the heat treatment effects and mechanical properties of alloys.

Mechanical property testing: Conduct mechanical property testing on Hastelloy alloy rods, including tensile strength, yield strength, elongation, impact toughness, etc. Commonly used testing methods include tensile testing, impact testing, etc.

Corrosion resistance test: Hastelloy alloy is mainly used in corrosion-resistant applications, so corrosion resistance testing is essential. Commonly used methods include electrochemical corrosion testing, salt spray testing, acid-base corrosion testing, etc.

Other tests: Based on demand, specific quality tests such as heat treatment effect evaluation, hardness testing, ultrasonic testing, and magnetic particle testing can also be performed.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China