0

0

Products Description

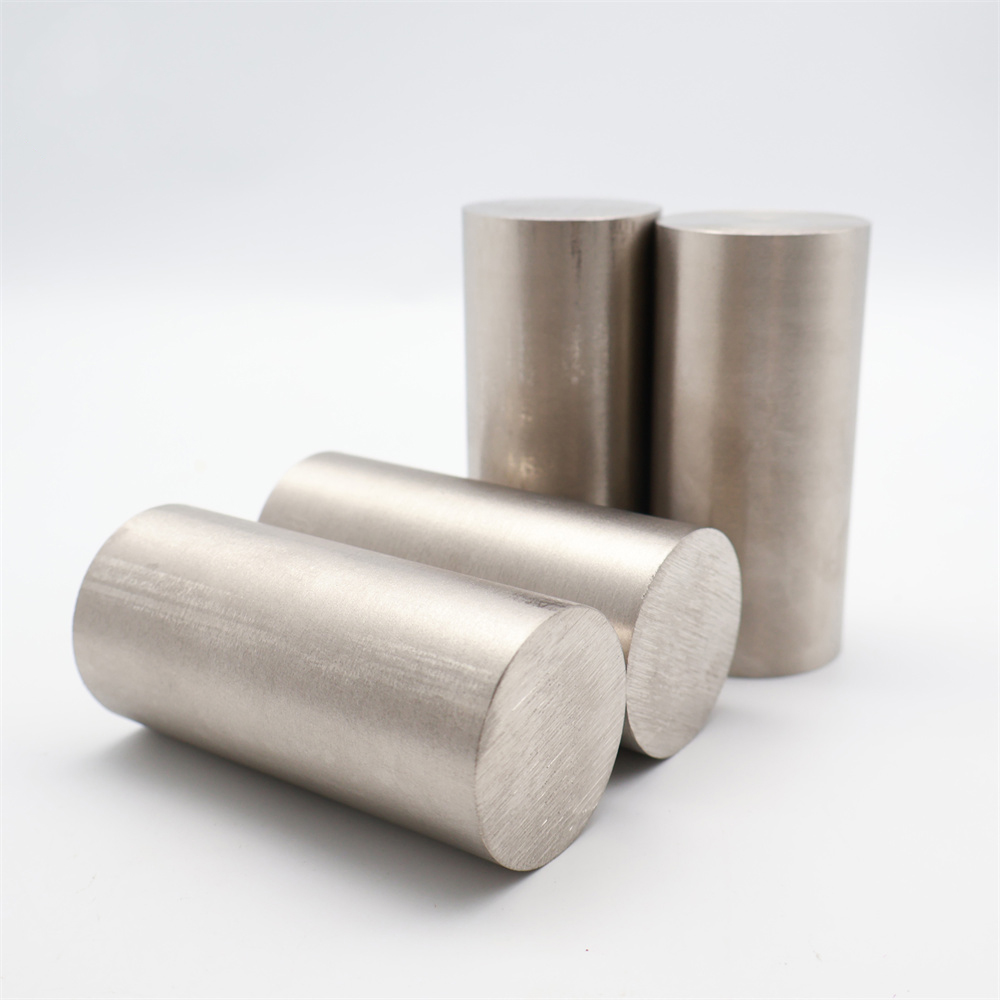

Hastelloy alloy rods play an important role in scrap processing equipment. Scrap processing equipment needs to face various corrosive and high-temperature environments, and Hastelloy alloy rods are favored for their excellent corrosion resistance and high-temperature strength. Hastelloy alloy rod is composed of nickel, molybdenum, chromium and other elements. It has excellent acid resistance, alkali resistance, oxidation resistance and corrosion resistance, and can resist corrosive media in waste materials, such as acidic waste liquid, organic solvents and chemical substances. It also has excellent mechanical properties and is able to withstand the high temperature and pressure conditions found in waste processing equipment. Hastelloy alloy rods can be used to manufacture key components in waste treatment equipment, such as reactors, heat exchangers, pipes and valves. Its stability and reliability enable the waste processing equipment to operate for a long time and effectively handle various waste materials. Hastelloy alloy rods are widely used in the scrap processing industry, contributing to environmental protection and sustainable development.

Product Information

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.00-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | Customized |

Plate | Customized |

Hastelloy grades: Hastelloy C276, Hastelloy C22, Hastelloy C-2000, Hastelloy C-4, Hastelloy C, Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy X, Hastelloy G-30, Hastelloy G-35, etc.

UNS N10276, UNS N06022, UNS N06200, UNS N10665, UNS N10675, UNS N06030, UNS N06002, etc. Hastelloy seamless pipes, steel plates, round bars, forgings, flanges, H-rings, welded pipes, steel strips, straight bars, wires and supporting welding consumables, processed parts, etc.

Hastelloy | |||||||||||

Grade | Ni | Cr | Mo | W | Co | C | Mn | Si | S | P | Other |

C-276 | Rem | 15-16.5 | 15-17 | 3-4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.001 | 0.015 | V0.1-0.3 |

C-22 | 56-59 | 20-22.5 | 12.5-14.5 | 2.5-3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.02 | V0.35 | |

C-2000 | Rem | 22-24 | 15-17 | 2 | 0.01 | 0.5 | 0.06 | 0.01 | 0.025 | A10.5 Cul.6 | |

B-2 | Rem | 0.4-0.7 | 26-30 | 1 | 0.01 | 1 | 0.08 | 0.01 | 0.02 | Cu0.5 | |

B-3 | 65 | 1-3 | 27-32 | 3 | 3 | 0.01 | 3 | 0.1 | 0.01 | 0.03 | Vo.2 A10.5 Ti0.2 Cuo.2 |

G-30 | Rem | 28-31.5 | 4-6 | 1.5-4 | ≤5 | 0.03 | ≤2 | ≤1 | ≤0.02 | ≤0.04 | Nb/Ta0.3-1.5 Cul-2.4 |

X | Rem | 20.5-23.5 | 8-10 | 0.2-1 | 0.5-2.5 | 0.05-0.15 | 1 | 1 | 0.015 | 0.025 | A10.5 Ti0.15 B0.005 |

C-4 | Rem | 14-18 | 14-17 | 2 | 0.015 | 1 | 0.08 | 0.7 | 0.04 | Ti0.7 | |

G-35 | 8-10 | 5 | 2 | 0.03 | 2-3 | 1.5 | 1 | 2 | 0.02 | Cu0.04 | |

C | Rem | 14.5-17.5 | 15-17 | 3-4.5 | 0.03 | 1 | 0.03 | 0.04 | |||

Hastelloy | Density (g/cm3) | Melting point (℃) | Elongation A5 (%) | Tensile Strength (Rm N/mm2) | Yield Strength (RP0.2N/mm2) |

C-276 | 8.9 | 1325-1370℃ | 62 | 758 | 363 |

C-22 | 8.9 | 1325-1370 ℃ | 40 | 690 | 283 |

C-2000 | 8.5 | 1399℃ 2550°F | 45 | 690 | 283 |

B-2 | 9.2 | 1330-1380℃ | 40 | 745 | 325 |

B-3 | 9.22 | 1370-1418℃ | 40 | 760 | 350 |

G-30 | 8.22 | 1399℃ 2550°F | 62 | 524 | 200 |

X | 8.3 | 1260-1355℃ | 30 | 690 | / |

C-4 | 8.64 | 399°C 2550°F | 40 | 690 | 280 |

G-35 | 8.22 | 1370-1400℃ | / | / | / |

C | 8.94 | 1330-1380 ℃ | 40 | 690 | 310 |

For more details, pls directly contact us.

Characteristic:

Corrosion resistance: Hastelloy alloy rods have excellent corrosion resistance and can withstand the erosion of acidic, alkaline and oxidizing media in waste processing equipment.

High Temperature Strength: This alloy rod maintains excellent strength and stability in high temperature environments and is able to withstand the high temperature and pressure conditions found in scrap processing equipment.

Resistance to stress corrosion cracking: Hastelloy alloy rods exhibit excellent resistance to stress corrosion cracking and can operate stably for a long time in stress environments.

Advantage:

Strong corrosion resistance: Hastelloy alloy rods can resist the erosion of various corrosive media in waste treatment equipment, including acidic waste liquids, organic solvents and chemical substances, extending the service life of the equipment.

High-temperature stability: The alloy rod maintains excellent strength and stability in high-temperature environments and can meet the high-temperature tolerance requirements of scrap processing equipment.

Resistance to stress corrosion cracking: Hastelloy alloy rods exhibit excellent resistance to stress corrosion cracking, reducing the risk of equipment breaking under stress environments.

Specific applications in waste treatment equipment:

Reactor: Hastelloy alloy rods can be used to make reactors in waste processing equipment to withstand the chemical reactions of waste and high-temperature environments.

Heat exchanger: This alloy rod can be used to manufacture heat exchanger tube bundles to achieve heat exchange and energy recovery of waste materials.

Pipes and valves: Hastelloy alloy rods can be used to manufacture pipes and valves in waste processing equipment to ensure stable waste flow and prevent leaks.

Related knowledge points:

Hastelloy alloy rods can be tested for compatibility with different types of scrap materials to ensure their suitability in a specific scrap processing environment.

Hastelloy alloy rods can also be machined and customized through processes such as welding, forging and machining to meet the requirements of specific scrap processing equipment.

Hastelloy alloy rods in scrap processing equipment should be regularly maintained, cleaned and inspected to ensure their performance and longevity.

In conclusion, Hastelloy alloy rod is an ideal material choice in scrap processing equipment due to its excellent corrosion resistance, high temperature strength and resistance to stress corrosion cracking.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China