0

0

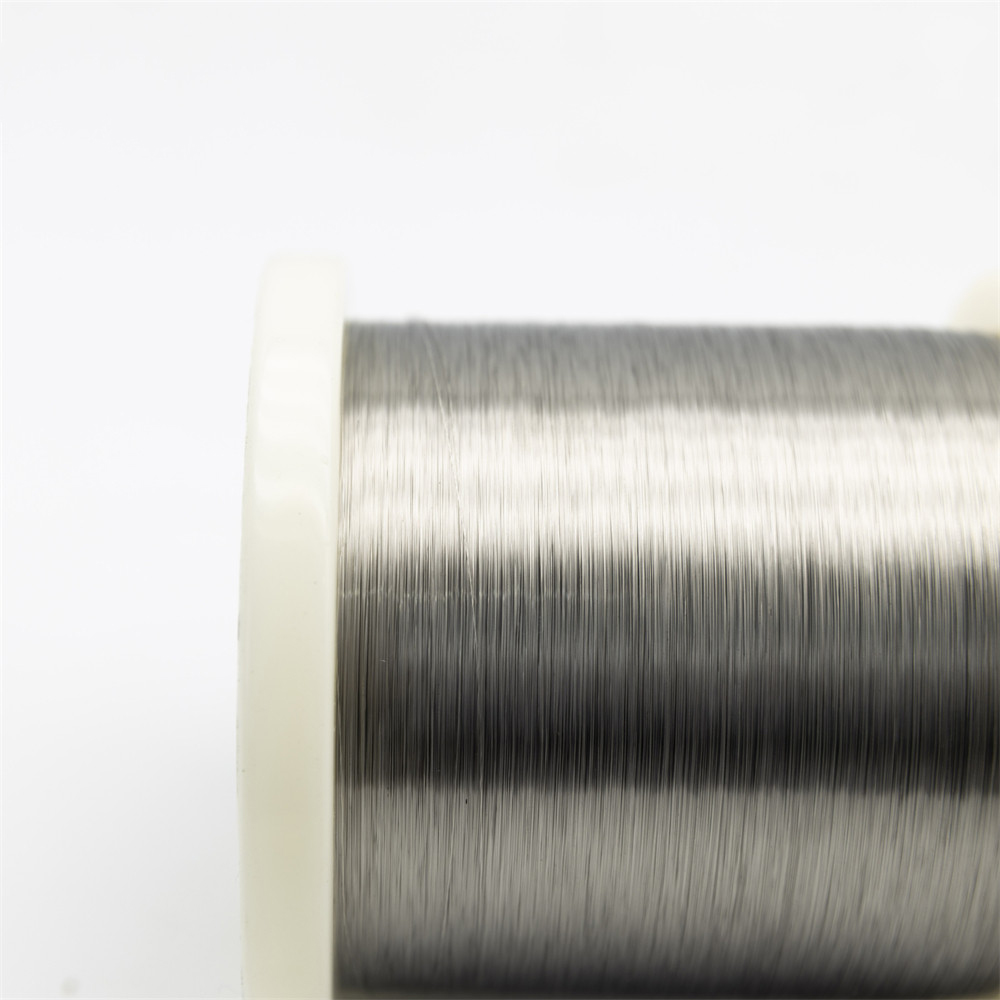

Products Description

Anti-corrosion pure nickel wire is mainly used in the oil and gas industry to manufacture corrosion-resistant equipment and pipelines to cope with harsh working environments and corrosive media. They can be used to manufacture various types of equipment such as tanks, pipes, valves and heat exchangers. Anti-corrosion pure nickel wire performs well in high temperatures and acidic environments, providing long-term corrosion resistance to ensure equipment reliability and safety.

In addition, anti-corrosion pure nickel wire also has good processability and weldability, making it easy to manufacture components of various shapes and sizes. They are usually machined and formed by methods such as cold drawing, hot drawing or electrical discharge machining.

Dimension:

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

Size Range | |

Wire | 0.025-10mm |

Ribbon | (0.50-0.25)*(0.5-6)mm |

Strip | (0.05-0.5)*(5-200)mm |

Corrosion resistance

Pure nickel wire has excellent corrosion resistance in high temperature environments. Here are some relevant features and benefits:

Oxidation resistance: Pure nickel wire can resist oxidation reactions at high temperatures and form a dense oxide film, effectively blocking further oxidation. This gives pure nickel wire good corrosion resistance in high temperature atmospheres.

Acid resistance: Pure nickel wire has good corrosion resistance to most acidic media. It can resist the erosion of sulfuric acid, hydrochloric acid, nitric acid and other acidic substances, thus playing an excellent role in high-temperature acidic environments.

Alkali resistance: Pure nickel wire also shows good corrosion resistance to alkaline media. It can resist the erosion of alkaline substances such as sodium hydroxide and potassium hydroxide, and is suitable for high-temperature alkaline environments.

Sulfide resistance: Pure nickel wire has certain resistance to sulfide corrosion. In high-temperature environments containing sulfides, pure nickel wire can maintain good corrosion resistance.

Stability: Pure nickel wire has good stability in high temperature environments, is not prone to phase change or creep, and can maintain its physical and chemical properties for a long time.

For more details, pls directly contact us.

Advantages

Pure nickel wire has some obvious advantages over other materials in some aspects, including:

Corrosion resistance: Pure nickel wire has excellent corrosion resistance in various corrosive media, including acidic, alkaline and oxidizing media. This allows pure nickel wire to maintain longer durability and reliability in harsh working environments.

High temperature stability: Pure nickel wire has good stability in high temperature environments and is not prone to phase change or creep. It maintains stable physical and chemical properties and is suitable for high temperature processes and applications.

Mechanical properties: Pure nickel wire has good mechanical properties, including high strength, good ductility and plasticity. This makes pure nickel wire easy to process and shape, suitable for various complex shape manufacturing needs.

Welding performance: Pure nickel wire has excellent welding performance and can make good welding connections with other materials. This allows the pure nickel wire to be easily connected to other components or equipment, providing a complete system solution.

Reliability and Durability: Due to its corrosion resistance and high temperature stability, pure nickel wire is able to provide long-term reliability and durability. This enables pure nickel wire to ensure safe operation and long-term use in critical applications such as equipment and pipe manufacturing in the oil and gas industry.

Disadvantages

Pure nickel wire may have some disadvantages in some aspects compared to other materials, including:

Cost: The cost of pure nickel wire is generally higher relative to some common materials such as carbon steel or stainless steel. This is due to the scarcity and high purity requirements of nickel itself.

Thermal conductivity: The thermal conductivity of pure nickel wire is relatively low compared to some other metallic materials and may not be as good as materials with better thermal conductivity such as copper or aluminum. In some applications where excellent thermal conductivity is required, pure nickel wire may not be the best choice.

Strength and hardness: Pure nickel wire may have lower strength and hardness than some high-strength engineering materials, such as titanium alloy or high-strength stainless steel. In some applications where high strength and rigidity are required, pure nickel wire may not be suitable.

Magnetism: Pure nickel wire is a ferromagnetic material and has magnetic properties. In some specific applications, such as electromagnetic shielding or magnetic field sensitive equipment, the magnetic properties of pure nickel wire may impose some limitations.

Application

In addition to its application in the oil and gas industry, pure nickel wire is also widely used in the following fields:

Chemical industry: Pure nickel wire is widely used in the chemical industry to manufacture corrosion-resistant equipment and pipelines, such as chemical reactors, distillation towers, heat exchangers and storage tanks.

Food Processing: It is used in the food processing industry to manufacture food processing equipment such as food heaters, ovens and stoves, etc.

Aerospace: Pure nickel wire is widely used in the aerospace field. it

Electronic industry: Pure nickel wire is used in the electronic industry to manufacture resistors, heaters, thermistors and electronic components.

Medical devices: Pure nickel wire is used in the field of medical devices to make medical wires, implants, and surgical instruments.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China