0

0

Products Description

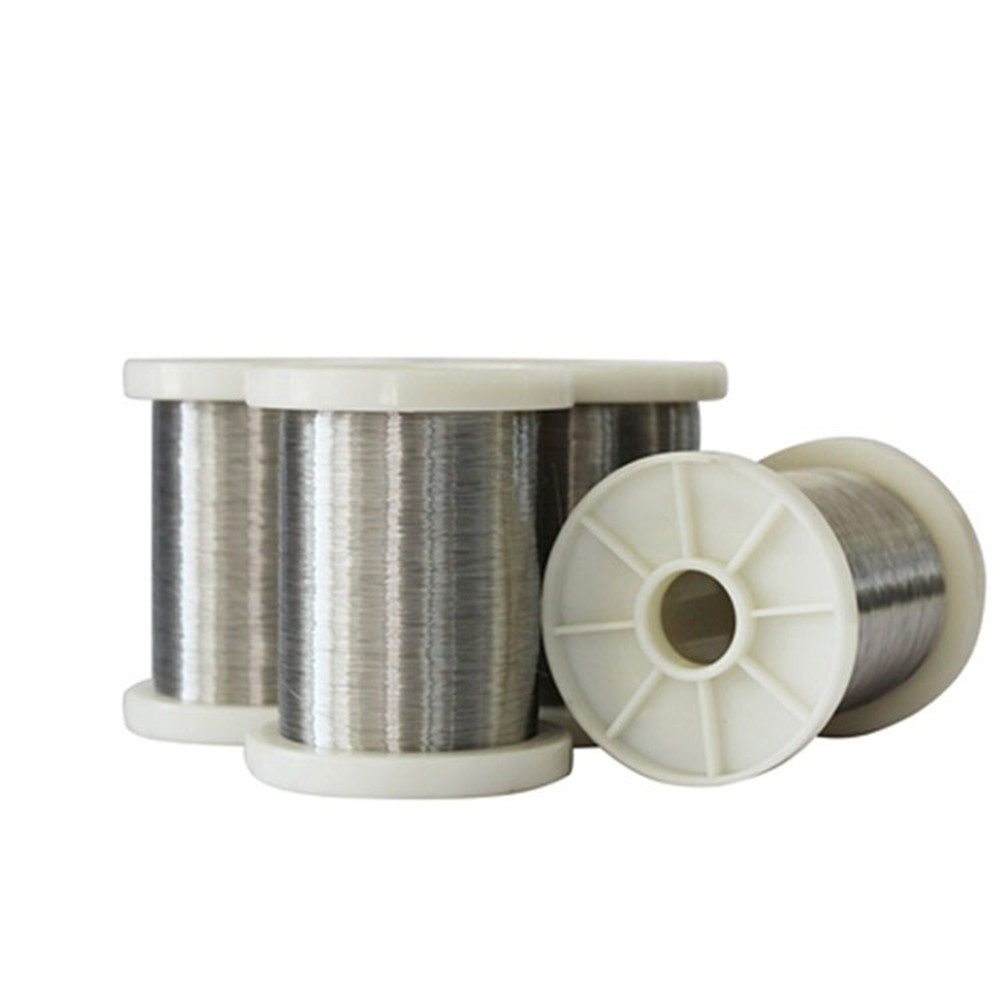

Pure nickel wire is a linear product made of high-purity nickel material. It is usually supplied in the form of reels or spools, and suppliers can provide specifications in different diameters and lengths according to customer needs. In the aerospace industry, pure nickel wire is widely used in the manufacture of various key components.

Pure nickel wire has excellent corrosion resistance, high temperature stability and mechanical properties in the aerospace industry, and is suitable for the manufacture of key components such as temperature sensors, heating elements, cables and connecting wires. Its lightweight design, corrosion resistance and high temperature applications make it widely used in the aerospace industry.

Dimension:

The thickness and dimensions can be met what customers required.

Parameter:

Purity: High-purity pure nickel wire usually has a nickel content of more than 99.5%, and the content of specific alloy elements can be adjusted through alloying modification.

Diameter: The diameter of pure nickel wire can vary depending on application needs, from a few microns to several millimeters.

Tensile Strength: The tensile strength of pure nickel wire usually ranges from 400 to 800 MPa, depending on the fineness of the material and how it is processed.

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

Size Range | |

Wire | 0.025-10mm |

Ribbon | (0.50-0.25)*(0.5-6)mm |

Strip | (0.05-0.5)*(5-200)mm |

Feature:

High temperature resistance: Pure nickel wire has excellent high temperature stability and can maintain structural stability and mechanical properties in high temperature environments.

Good electrical conductivity: Pure nickel wire has good electrical conductivity and is suitable for manufacturing parts that require high electrical conductivity in electronic devices.

Excellent mechanical properties: Pure nickel wire has good ductility and plasticity, and can be used for bending, stretching and shape processing.

Good oxidation resistance: Pure nickel wire can resist high temperature oxidation and corrosion, extending service life.

For more details, pls directly contact us.

Influencing factors

Pure nickel wire has many specific applications in the aerospace industry. Here are some of the common application areas:

Gas turbine engine: Pure nickel wire is widely used in gas turbine components of aircraft engines. These components include turbine blades, turbine discs, turbine disc rings, and nozzles. Pure nickel wire has excellent high temperature strength and corrosion resistance, and can withstand extreme working environments of high temperature, high pressure and corrosive gases.

Combustion devices: Pure nickel wire also has important applications in combustion devices. It is used to make spark plugs, ignition coils, burner wires and other components. These components require good high-temperature stability, oxidation resistance, and electrical conductivity to ensure reliable ignition and combustion.

Thermal protection system: The thermal protection system plays a vital role during the spacecraft's reentry into the atmosphere. Pure nickel wire is used to manufacture heat shields, thermal protection layers and thermal insulation structures. Pure nickel wire can withstand extremely high temperatures and maintain structural stability, effectively isolating and reducing heat conduction.

Electronic devices: Pure nickel wire is also used in aerospace electronic devices. For example, it is used to make temperature sensors, electric furnace heating elements, and resistance wires. Pure nickel wire's good electrical conductivity and high temperature stability make it an ideal material for these devices.

Structures and components: Pure nickel wire is also used to manufacture structures and components of aerospace devices. For example, it can be used to make wires, connectors, support rods and vibration damping materials. Pure nickel wire's high strength, corrosion resistance and lightweight properties make it important in aerospace structures.

In general, pure nickel wire is widely used in the aerospace industry in gas turbine engines, combustion devices, thermal protection systems, electronic devices, and structures and components of aerospace devices. Its high temperature strength, corrosion resistance and lightweight properties make it one of the important materials in the aerospace field.

Manufacturing process

The manufacturing process of pure nickel wire in the aerospace industry typically includes the following steps:

Material preparation: Select high-purity metallic nickel as raw material. The purity of nickel is usually required to be above 99.5% to ensure the quality of the final product.

Smelting and Preparation: Put high-purity nickel raw materials into the furnace for melting. Molten nickel is drawn into filaments from the molten metal through specific production processes, such as horizontal drawing, vertical drawing or jet drawing.

Cold drawing: The preliminary pure nickel wire produced by melting is drawn through a series of cold drawing processes. The purpose of cold drawing is to improve the mechanical properties and dimensional accuracy of pure nickel wire through continuous stretching. The process typically involves multiple passes of drawing, each of which gradually reduces the diameter of the filament while increasing its strength and ductility.

Annealing: Cold drawn pure nickel wire needs to be annealed to eliminate internal stress and restore its grain structure. During the annealing process, pure nickel wire is heated to a specific temperature and then slowly cooled to achieve structural stability and optimization of mechanical properties.

Surface Treatment: To meet the high requirements of the aerospace industry for pure nickel wire, surface treatment may be required. This includes steps such as surface oxide removal, cleaning and polishing to ensure the surface finish and purity of pure nickel wire.

Inspection and quality control: At all stages of the manufacturing process, pure nickel wire is subject to strict inspection and quality control to ensure that the product meets the specified technical requirements and standards. This includes dimensional measurements, mechanical property testing, chemical composition analysis, etc.

Packaging and Delivery: Quality inspected pure nickel wire is packed and ready for delivery to customers in the aerospace industry. Packaging is usually protected against moisture, oxidation, and damage to ensure that its quality and performance are maintained during transportation and use.

It should be noted that the manufacturing process of pure nickel wire may vary depending on specific product needs, specifications and suppliers, and the above steps are for general reference only. In the actual manufacturing process, there may be other specific processes and processing steps to meet the high requirements of the aerospace industry for pure nickel wire.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China