0

0

Products Description

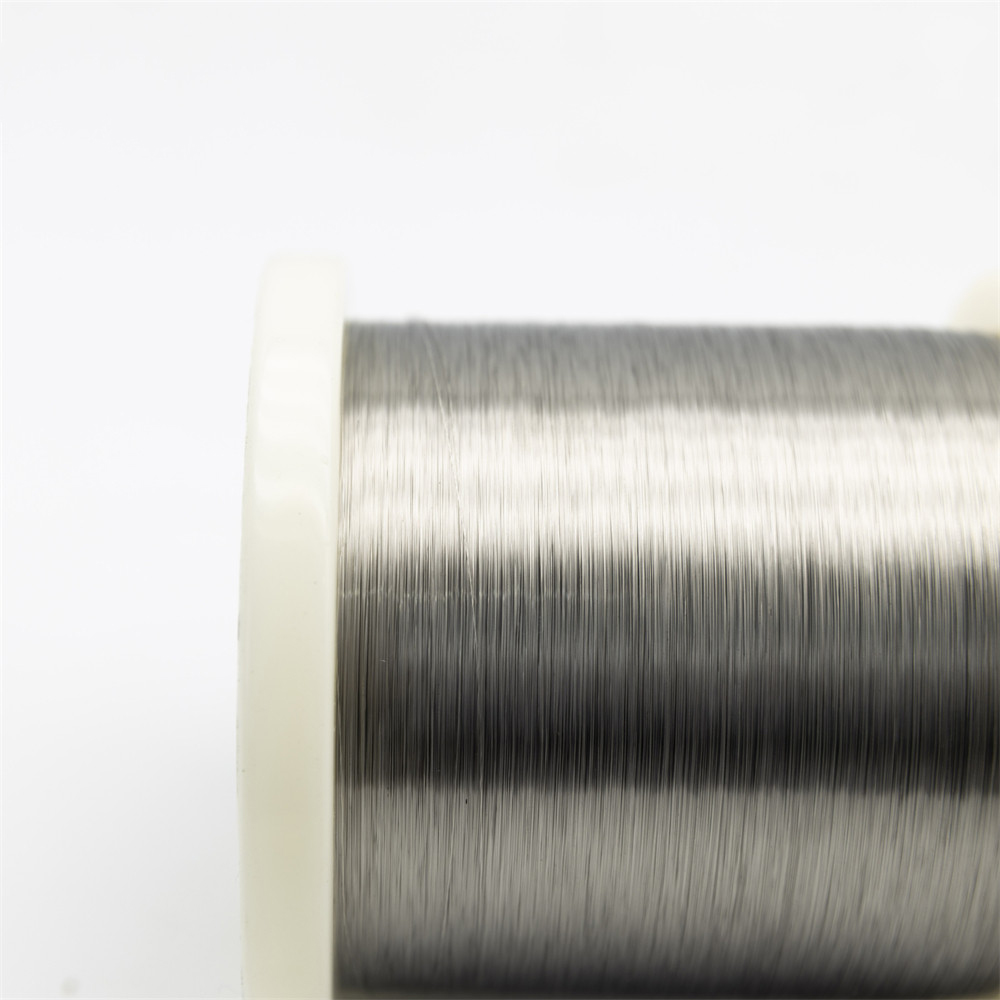

Pure nickel wire is a versatile material with a wide range of properties and applications. Whether in electronics, electrical engineering, heating elements or laboratory research, pure nickel wire plays an important role. Its high electrical conductivity, high thermal conductivity, corrosion resistance and magnetic properties make it one of the indispensable materials in many industries.

Pure nickel wire plays an important role in laboratory research and scientific experiments. It is often used as a thermocouple material to measure temperature and monitor heat. At the same time, pure nickel wire is also used to make experimental devices, electron microscopes and other scientific instruments.

Pure nickel wire is also widely used in the chemical processing, aerospace and marine industries due to its excellent corrosion resistance. The corrosion resistance of nickel enables pure nickel wire to be used for a long time in harsh environments and chemically strong media, such as seawater, acidic solutions and high-temperature corrosive environments.

Dimension:

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

Size Range | |

Wire | 0.025-10mm |

Ribbon | (0.50-0.25)*(0.5-6)mm |

Strip | (0.05-0.5)*(5-200)mm |

Production Process:

The production process of pure nickel wire can be summarized as the following main steps:

Raw material preparation: Select high-purity nickel material as raw material. These raw materials can be nickel ore or recycled nickel, and high-purity nickel metal can be obtained through processes such as ore beneficiation, smelting and refining.

Smelting and casting: Heat high-purity nickel metal to the melting point, then pour it into a suitable mold and cast it to obtain a preliminary nickel billet.

Hot rolling and cold rolling: The preliminary nickel billet is deformed through hot rolling or cold rolling processes. Hot rolling is performed at high temperatures, which can achieve larger deformation; cold rolling is performed at room temperature, which can obtain higher material strength and surface quality.

Annealing treatment: The rolled nickel billet is annealed. By heating and controlling the cooling process, the stress is eliminated and the grain boundary structure is improved, thereby improving the plasticity and toughness of the pure nickel wire.

Drawing and stretching: The rolled and annealed nickel billet is drawn or stretched to gradually reduce the cross-sectional area and make it into a filament shape. This process requires multiple stages of drawing or stretching, each stage reducing the diameter and increasing the material's ductility.

Cleaning and testing: Clean the surface of the pure nickel wire obtained by drawing or stretching to remove impurities and contaminants. Then strict quality testing is carried out, including testing of size, chemical composition, physical properties, etc. to ensure that the product meets the requirements.

Packaging and leaving the factory: Pure nickel wire that meets quality standards is packaged. Commonly used packaging methods include winding, coiling, etc. Then it is marked and stored, and finally shipped out of the factory for use by customers or other production links.

For more details, pls directly contact us.

Production Process:

Production Process:

In the production of pure nickel wire, there are some important precautions and key factors that will have a critical impact on the quality of the product. Here are some of them:

Raw material selection: Choosing high-purity nickel materials as raw materials is the primary factor in ensuring product quality. The purity and quality of raw materials directly affect the purity and performance of the final product.

Production process control: Strict control of production process parameters, such as heating temperature, cooling speed, rolling intensity, etc., can ensure the uniformity, stability and consistency of the product. Reasonable process control can prevent defects and unevenness and improve product quality.

Cleaning and anti-pollution measures: During the production process, the production environment must be kept clean and dust-free to prevent impurities and pollutants from adhering to the product surface. Perform regular cleaning and maintenance of equipment and work areas to reduce the possibility of product contamination from the outside.

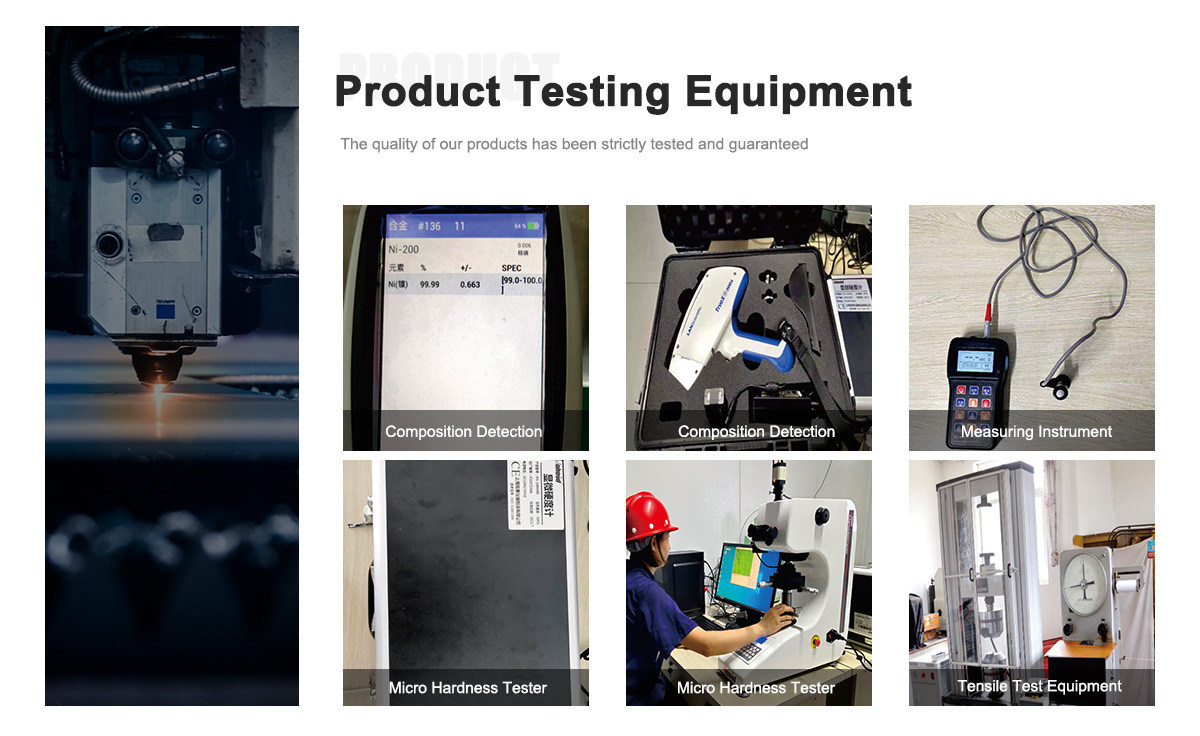

Quality testing and control: Establish a complete quality control system and conduct strict quality testing. Including inspection and testing of product size, chemical composition, physical properties, etc. Through reasonable sampling and testing methods, we ensure that products comply with specified technical standards and customer requirements.

Annealing treatment: Proper annealing treatment during the production process can eliminate stress, improve the grain boundary structure and improve the plasticity and toughness of the product. Reasonable annealing parameters and processes have an important impact on product performance and quality.

Packaging and storage: Proper packaging and storage methods can protect products from the external environment and prevent oxidation, corrosion and contamination. Appropriate packaging materials and methods, as well as appropriate storage conditions, can maintain product quality and performance.

To sum up, by strictly controlling the quality of raw materials, optimizing production processes, strengthening quality testing and control, and paying attention to packaging and storage precautions, it is possible to ensure that the quality and performance of pure nickel wire products meet the requirements.

Production Process:

Our company's quality assurance for pure nickel wire products is always based on high-purity raw materials, advanced production technology and strict quality control. We are committed to ensuring that our products comply with international standards and customer requirements through comprehensive testing and verification. We focus on surface quality and are committed to providing high-quality, reliable pure nickel wire products that meet customer needs.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China