0

0

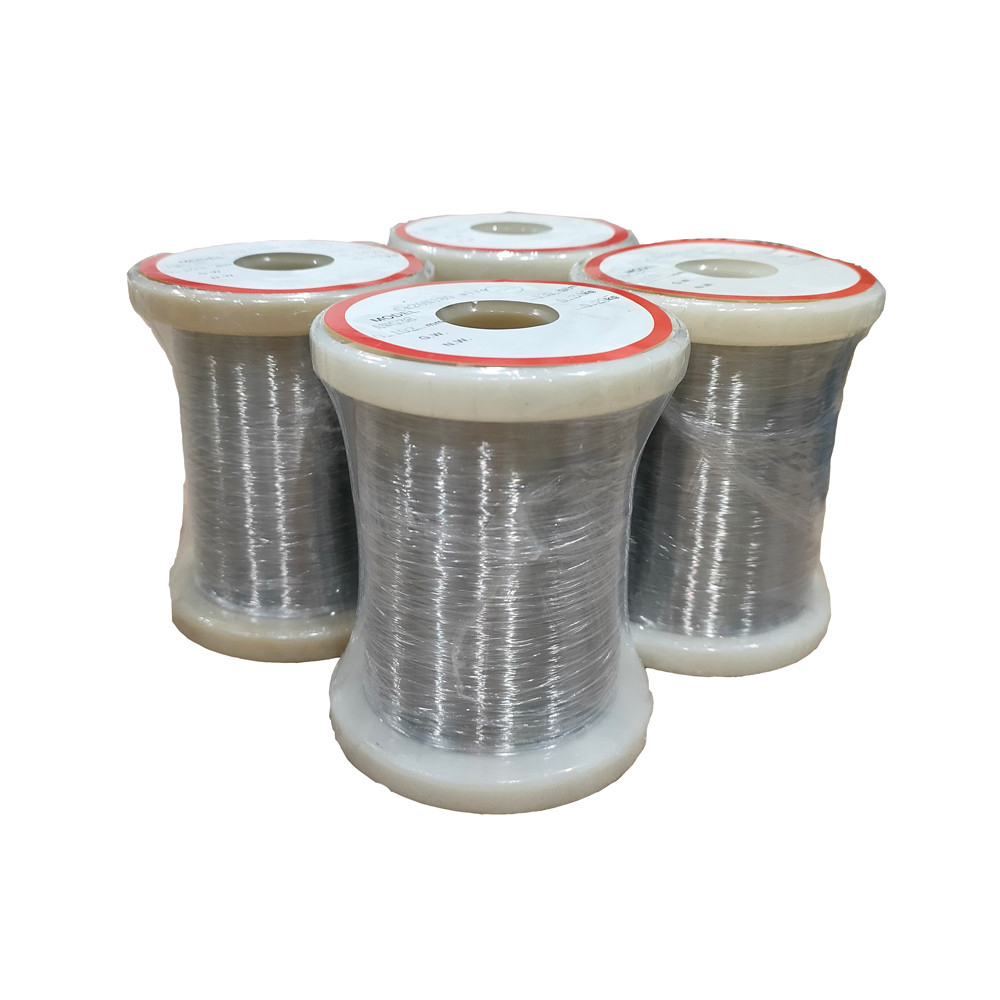

Products Description

Monel wire is a high-performance nickel-copper alloy wire that is widely used in many fields. It has excellent corrosion resistance, high temperature performance and mechanical properties, and is widely used in petrochemical, marine engineering, aerospace and other fields. Monel wire can not only resist the erosion of acidic, alkaline and salt media, but also maintain stable performance in high temperature and high pressure environments. Its high strength, good plasticity and weldability make it ideal for manufacturing key components such as corrosion-resistant equipment, valves, pipelines and more. Whether in extreme marine environments or harsh industrial conditions, Monel wire can provide reliable solutions to meet various demanding engineering requirements.

Parameter:

Diameter range: from 0.15mm to 7.5mm

Standard specifications: usually comply with relevant standards such as ASTM B164

Typical chemical composition: nickel (minimum 63%), copper (28-34%), iron (maximum 2.5%), manganese (maximum 2.0%), carbon (maximum 0.3%), etc.

Typical mechanical properties: minimum tensile strength 550 MPa, minimum yield strength 240 MPa, minimum elongation at break 40%

Item | Ni | Cu | Fe | Mn | C | Si | S |

Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

For more details, pls directly contact us.

Characteristic:

Corrosion resistance: Monel wire has excellent corrosion resistance and can resist erosion by corrosive media such as acid, alkaline, salt water, sea water, chloride, sulfide and other corrosive media.

High temperature performance: It can maintain stability and strength in high temperature environments, and has good high temperature oxidation and high temperature corrosion resistance.

Resistance to stress corrosion cracking: Monel wire exhibits high resistance to stress corrosion cracking, maintaining structural integrity even in high stress environments.

Mechanical properties: It has high tensile strength, yield strength, and certain ductility and plasticity.

Non-magnetic: Typically non-magnetic, suitable for applications that are sensitive to magnetic fields.

Advantage:

Excellent corrosion resistance: Monel wire has excellent corrosion resistance in various corrosive environments, which can extend the service life of equipment and reduce maintenance costs.

High temperature application capability: Due to its good high temperature performance, Monel wire is suitable for use in high temperature processes and equipment, and can maintain stability and reliability.

Resistance to stress corrosion cracking: Its high resistance to stress corrosion cracking makes Monel wire a reliable choice in high-stress environments, reducing the risk of equipment breakage and damage.

Excellent mechanical properties: high strength and plasticity, easy to process and shape, and adaptable to diverse manufacturing needs.

application:

Application:

Oil and natural gas industry: used in the manufacture of components and pipelines in oil extraction equipment, petrochemical plants, natural gas processing equipment, etc.

Marine engineering: suitable for submarine pipelines, offshore platform equipment, seawater treatment systems, etc. in marine environments.

Chemical industry: used in corrosion-resistant medium transmission pipelines, storage tanks, heat exchangers and chemical reactors, etc.

Aerospace: Suitable for high-temperature, corrosion-resistant applications such as aircraft engine components, gas turbines, and propulsion devices.

Electronic equipment: Since Monel wire is usually non-magnetic, it is suitable for applications such as electronic equipment, magnetically sensitive devices and medical instruments that require reduced magnetic field interference.

In general, Monel wire has excellent corrosion resistance, high temperature performance, stress corrosion cracking resistance and mechanical properties, and is widely used in petroleum, chemical industry, marine, aerospace and electronics and other fields. It is a reliable, durable alloy wire material capable of meeting the needs of harsh environments and demanding high-performance applications.

FAQ:

Q: Can Monel silk be customized according to customer needs?

A: Yes, Monel wire can be customized according to customers' specific needs, such as different diameters, different shapes, etc.

Q: How is the packaging and logistics of Monel silk handled?

A: Monel wire will usually be packed in appropriate packaging materials, such as plastic rolls, cartons or wooden boxes. In terms of logistics, appropriate transportation methods, such as sea, air or land transportation, will be adopted to ensure that the products reach their destination safely.

Q: Does Monel wire have high strength?

A: Yes, Monel wire has high strength, which makes it ideal for manufacturing equipment and components with high strength requirements.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China