0

0

Products Description

Monel wire is a high performance nickel-copper alloy wire that has a wide range of applications in the oil and gas industry. Known for its excellent corrosion resistance, high temperature performance and mechanical properties, it meets the stringent requirements of the oil and gas industry for material strength and reliability. Monel wire can resist corrosion from acidic, alkaline and salty media while maintaining stable performance in high temperature and high pressure environments. This makes it ideal for manufacturing critical equipment and components in the oil and gas industry, such as pipes, valves, furnace tubes and well casings.

Parameter

Item | Ni | Cu | Fe | Mn | C | Si | S |

Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

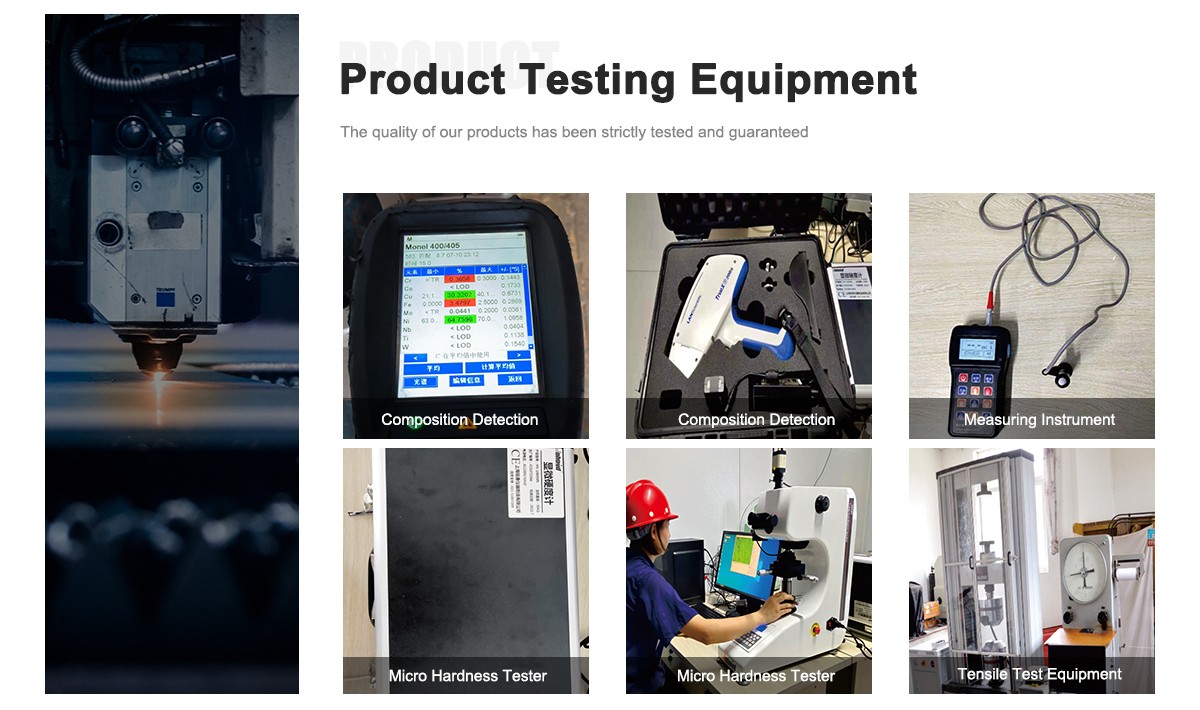

Quality Inspection

The quality inspection of Monel silk is an important link to ensure that the product meets the requirements. The following is a Chinese introduction to the quality inspection of Monel silk:

Dimensional measurement: Dimensional measurement is the process of detecting the diameter, length, width, thickness and other dimensions of Monel wire. Micrometers, vernier calipers, microscopes and other measuring tools are usually used to ensure that the size of the Monel wire meets the specified requirements.

Chemical composition analysis: Chemical composition analysis is the process of quantitatively analyzing the element content in Monel silk. Use spectrometers, mass spectrometers and other instruments to conduct chemical analysis on Monel silk samples to determine whether their components meet the standard requirements.

Mechanical property testing: Mechanical property testing is the process of evaluating the mechanical properties of Monel wire. Common mechanical property tests include tests of tensile strength, yield strength, elongation, hardness and other indicators. The mechanical properties of Monel wire are tested through tensile testing machines, hardness testers and other equipment to ensure that their mechanical properties meet the specified standards.

Corrosion performance test: Corrosion performance test is a process to evaluate the corrosion resistance of Monel wire to corrosive media. Common corrosion performance testing methods include salt spray test, immersion test, electrochemical test, etc. Monel wire is exposed to a simulated corrosion environment and its corrosion degree and surface changes are observed to evaluate its corrosion resistance.

Inspection report and quality control: All quality inspection results will be recorded in the inspection report to track and verify product quality. Inspection reports usually include product information, testing methods, testing results and evaluations. In addition, quality control measures and procedures are also implemented during the production process to ensure that the quality of Monel wire meets requirements.

Common inspection points and inspection times

In order to ensure that the quality of Monel wire meets the requirements, multiple inspections are usually required during the production process. Here are some common inspection points and times:

Raw material inspection: Before starting production, the Monel silk raw materials used are inspected. This includes testing the chemical composition, physical properties and appearance of raw materials to ensure that the quality of raw materials meets requirements.

Intermediate process inspection: Intermediate inspection is carried out at key links in the production process. This can include monitoring and inspection of drawing, cold working, heat treatment and other processes to ensure stable product quality at each production stage.

Final product inspection: After production is completed, the final Monel silk product is fully inspected. This includes dimensional measurement, chemical composition analysis, mechanical performance testing, corrosion performance testing, etc. to ensure that the quality of the product meets standard requirements.

Batch sampling inspection: In the case of mass production, a certain number of samples can be selected from the production batch for inspection through batch sampling inspection. This helps assess the quality status of the entire batch and ensures product consistency and stability.

Through multiple inspections during the production process, the quality of Monel silk can be comprehensively monitored and controlled, potential quality problems can be discovered and corrected in a timely manner, and the consistency and reliability of the product can be ensured. This helps to improve product quality levels, meet customer needs and ensure the performance and reliability of Monel wire in various fields of application.

Related test items

In addition to tests on dimensions, chemical composition, mechanical properties and corrosion properties, the quality inspection of Monel wire may also involve other tests such as temperature and pressure. Here are some relevant test items:

Temperature testing: Monel wire may need to undergo temperature testing to evaluate its performance and stability under different temperature conditions. This can include testing for antioxidant properties at high temperatures, coefficient of thermal expansion, etc. By exposing Monel wire to specific temperature conditions, performance testing and evaluation are performed to ensure that it performs well within the required operating temperature range.

Pressure Testing: For applications where pressure is required, Monel wire may need to be pressure tested. This can include pressure testing, burst testing, etc. By applying different pressure loads, the deformation, rupture and pressure resistance of the Monel wire are tested to ensure that it can safely and reliably withstand the required pressure environment.

These temperature and pressure tests are conducted based on specific application requirements and are designed to verify the performance and reliability of Monel wire under different working conditions.

FAQ

Q: What is the thermal conductivity of Monel wire?

A: The thermal conductivity of Monel wire is low, and compared with other metals, the thermal conductivity is weak.

Q: Is Monel wire resistant to stress corrosion cracking?

A: Yes, Monel wire has strong resistance to stress corrosion cracking and is suitable for environments subject to a combination of stress and corrosion.

Q: Does Monel wire have good welding performance?

A: Monel wire has good welding performance and can be connected and processed by conventional welding methods.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China