0

0

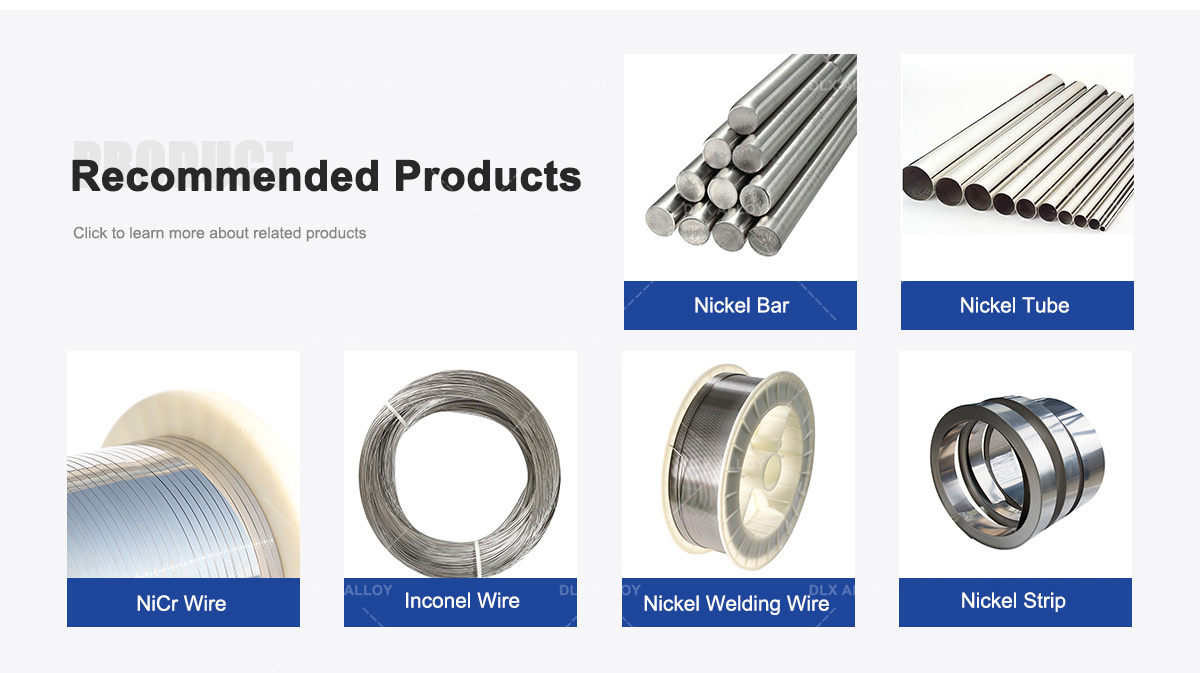

Products Description

Monel wire is a high-performance nickel-copper alloy wire that is widely used in many fields. It has excellent corrosion resistance, high temperature performance and mechanical properties, and is widely used in petrochemical, marine engineering, aerospace and other fields. Monel wire can not only resist the erosion of acidic, alkaline and salt media, but also maintain stable performance in high temperature and high pressure environments. Its high strength, good plasticity and weldability make it ideal for manufacturing key components such as corrosion-resistant equipment, valves, pipelines and more.

Corrosion resistance

Monel wire is an alloy wire with excellent corrosion resistance, mainly composed of nickel and copper. It has excellent anti-corrosion properties and can resist erosion by corrosive media such as acid, alkaline, salt water, sea water, chloride and sulfide. Monel wire is usually used in applications that require use in harsh corrosive environments.

The corrosion resistance of Monel wire comes from its special chemical composition and microstructure. Nickel as the main component provides good corrosion resistance, while the addition of copper enhances the strength and hardness of the alloy. In addition, Monel wire may contain other elements such as iron and manganese to further improve its corrosion resistance.

Monel wire is widely used in many industries and applications. It is often used in equipment such as pipelines, valves and storage tanks in the petroleum and chemical industries, as well as in subsea pipelines, offshore platforms and seawater treatment systems in offshore engineering. In addition, Monel wire is also used in engine components, gas turbines and propulsion devices in the aerospace industry, as well as in applications sensitive to magnetic fields such as electronic equipment and medical instruments.

All in all, Monel wire is widely used in industrial fields because of its excellent corrosion resistance. Whether in corrosive media or high temperature environments, Monel wire can maintain its performance and stability, providing reliable solutions for a variety of applications.

Parameter:

Item | Ni | Cu | Fe | Mn | C | Si | S |

Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

Influencing factors:

Nickel corrosion resistance: One of the main components of Monel wire is nickel, and nickel itself has excellent corrosion resistance. Nickel can form a dense oxide film or passive film to prevent the corrosive medium from further corroding the alloy. This passive membrane can stably exist in different corrosive environments and provides good protection.

Reinforcing effect of copper: The copper content in Monel wire is relatively high, and the addition of copper can enhance the strength and hardness of the alloy. At the same time, copper also has certain corrosion resistance properties, which can improve the overall corrosion resistance of the alloy.

Other alloying elements: Monel wire may contain other elements such as iron and manganese. The addition of these elements can further improve the corrosion resistance of the alloy and increase its stability and corrosion resistance.

Microstructure: The microstructure of Monel wire also affects its corrosion resistance. Factors such as phase distribution, grain size and grain boundary properties in the alloy will affect the corrosion behavior of the alloy. The uniform structure and fine grain size of the alloy generally contribute to improved corrosion resistance.

Improve ways to improve performance

Heat treatment: Monel wire can be heat treated to improve its mechanical properties and corrosion resistance. Common heat treatment methods include solution treatment and aging treatment. Solution treatment uniformly distributes the solutes in the alloy by heating to a specific temperature and then rapidly cooling to fix the solutes. Aging treatment maintains the alloy at an appropriate temperature for a period of time to precipitate the solute in the alloy and form a strengthening phase, thereby improving the strength and hardness of the alloy.

Temperature dependence: Monel wire properties may vary at different temperatures. In high-temperature environments, the high-temperature oxidation and high-temperature creep behavior of alloys require special attention. High-temperature oxidation of alloys refers to the reaction with oxygen at high temperatures to form an oxide layer, while high-temperature creep refers to plastic deformation under high temperatures and stress. Therefore, the temperature dependence and stability of Monel wire need to be considered in high temperature applications.

Manufacturing and processing: Monel wire can be shaped and processed through various processing methods, such as cold drawing, cold rolling, hot rolling, welding and casting, etc. However, it should be noted that Monel wire has higher tensile strength and hardness, so appropriate processing parameters and techniques may need to be adopted during processing to ensure the performance and quality of the alloy.

Environmental limitations: Although Monel wire has excellent corrosion resistance, it is not absolutely resistant to all corrosive media. For extremely corrosive media, detailed corrosion assessment and testing is required to determine the suitability and limitations of Monel wire.

FAQ

Q: What are the main characteristics of Monel silk?

A: Monel wire has excellent corrosion resistance, high temperature performance and mechanical properties.

Q: What are the applications of Monel wire in the petrochemical industry?

A: In the petrochemical industry, Monel wire is often used to manufacture key components such as corrosion-resistant equipment, valves, and pipelines.

Q: What are the unique features of Monel silk compared with other materials?

A: Monel wire has higher corrosion resistance and high temperature stability than other materials, and can maintain stable performance in harsh environments.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China