0

0

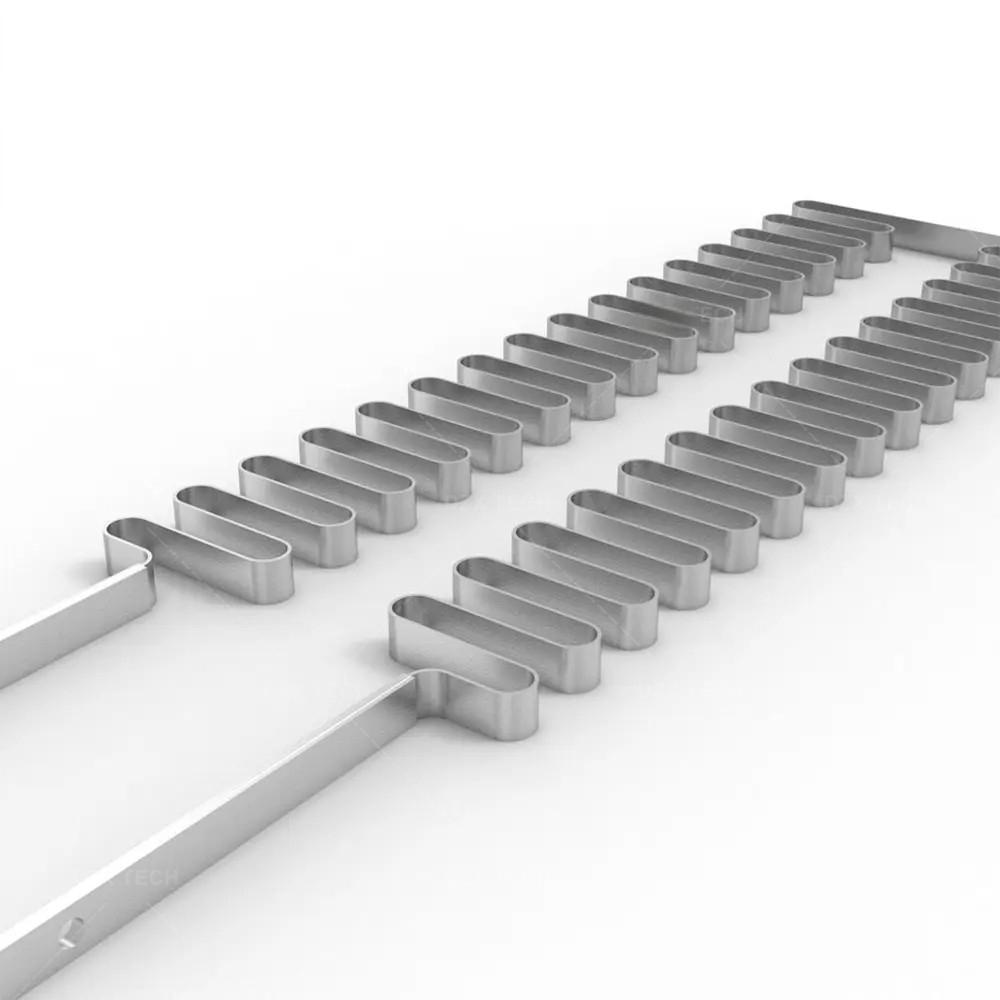

Products Description

FeCrAl coil wire is an important high-temperature alloy wire, including various grades such as 1Cr13Al4, 0Cr15Al5, 0Cr19Al3, 0Cr21Al4, 0Cr21Al6, 0Cr23Al5, 0Cr25Al5, 0Cr21Al6Nb, etc. The main components of these alloy wires are elements such as iron (Fe), chromium (Cr), aluminum (Al), etc. Different grades of alloy wires have slightly different compositions and performance parameters. They collectively possess high electrical resistivity, good high-temperature stability, and antioxidant performance, which can provide stable performance in high-temperature environments. These alloy wires are widely used in fields such as electric furnaces, heaters, and engine preheating systems, providing reliable heating solutions for various high-temperature heating scenarios.

Parameter:

Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

-- | -- | -- | -- | -- | -- | -- | ||

Max.Continuous service temp. of element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity at 20C(μΩ.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal Conductivity(KJ/m.h) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

Coefficient of lines expansion(αx10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting Point Approx(degree) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile Strength(N/mm) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

continuous service time(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Shape | Size (mm) |

Wire | 0.05-7.5 |

Rod | 8-50 |

Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

For more details, pls directly contact us.

Feature:

High resistivity: FeCrAl coil wires have a high resistivity, allowing them to quickly generate heat when energized, making them suitable for various heating applications.

High temperature stability: In high-temperature environments, FeCrAl coil wires exhibit good stability, are not easily softened, deformed or oxidized, and maintain long-term reliable performance.

Antioxidant performance: This type of coil wire has good antioxidant properties, which are not easy to oxidize or fail even when working for a long time at high temperatures, extending its service life.

Application:

Industrial heating equipment: FeCrAl coil wires are commonly used in various industrial heating equipment, such as heat treatment furnaces, melting furnaces, drying equipment, etc., providing stable and efficient heating.

Household appliances: Widely used in household appliances, including ovens, water heaters, electric stoves, etc., as heating elements, providing fast and uniform heating effects.

Automotive industry: Used for components such as engine preheating systems and seat heaters in automobiles, it improves the mild performance of car starting and increases comfort.

Q&A:

What are the advantages of FeCrAl coil wires?

High temperature stability, high electrical resistivity, and strong oxidation resistance.

What are the applications of FeCrAl coil wires?

Industrial heating equipment, household appliances, automotive industry.

What are the advantages of FeCrAl coil wires compared to other materials?

Good stability, fast heating, and long lifespan in high-temperature environments.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China