0

0

Products Description

CuBe2 C17500 C17200 Beryllium Copper Rod/Bar Manufacturer | |

*Material | Be, Cu, Co, Ni, Si, Fe, Al |

*Grade | CuBe2 C17200 |

*Tensile strength (Mpa) | 1105 |

*Density (g/cm3) | 8.83 |

*Softening temperature (℃) | 930 |

*Hardness (HRC) | 38-44 |

*Thermal conductivity (W/m.k20℃) | 105 |

*Conductivity (IACS%): | 18 |

c17200 beryllium copper is a kind of imported beryllium copper.

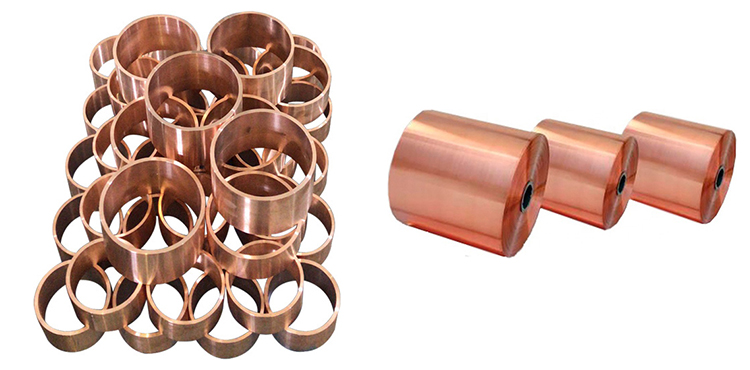

c17200 beryllium copper, the full range of beryllium copper is known as "the king of non-ferrous metal elasticity". It is used for all kinds of micro-motor brushes, switches, relays,connectors, temperature sensors that require high strength, high elasticity, high hardness, and high wear resistance. With the increasing requirements for the reliability and service life of the springs and various springs of the controller, the demand for beryllium copper will also increase.

Features

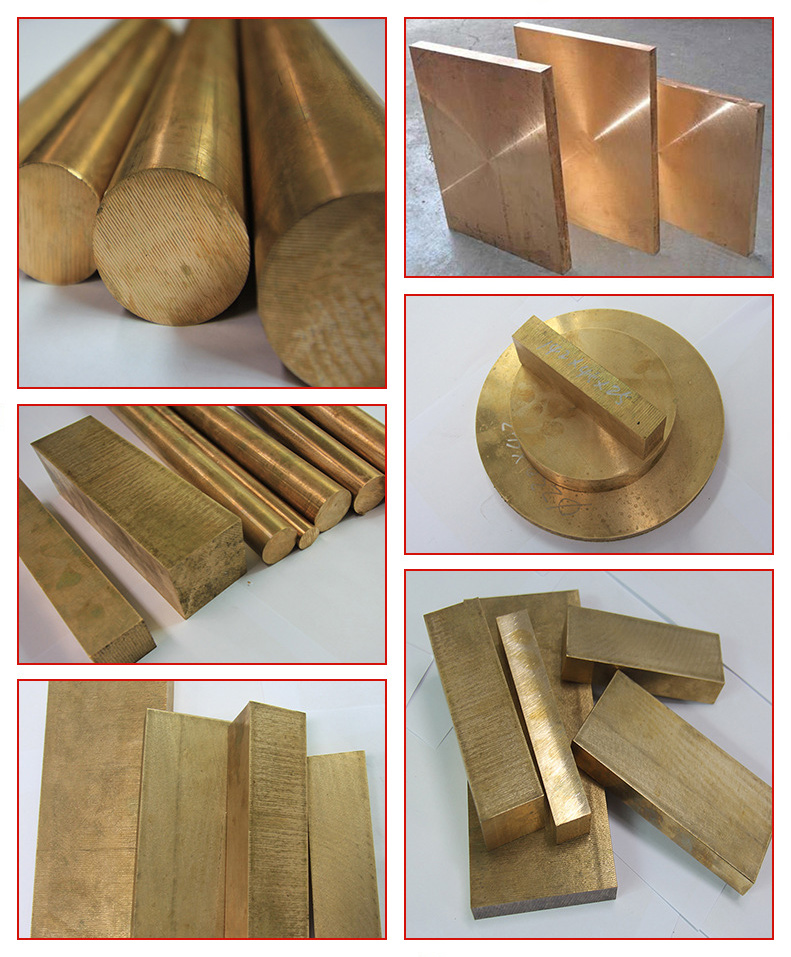

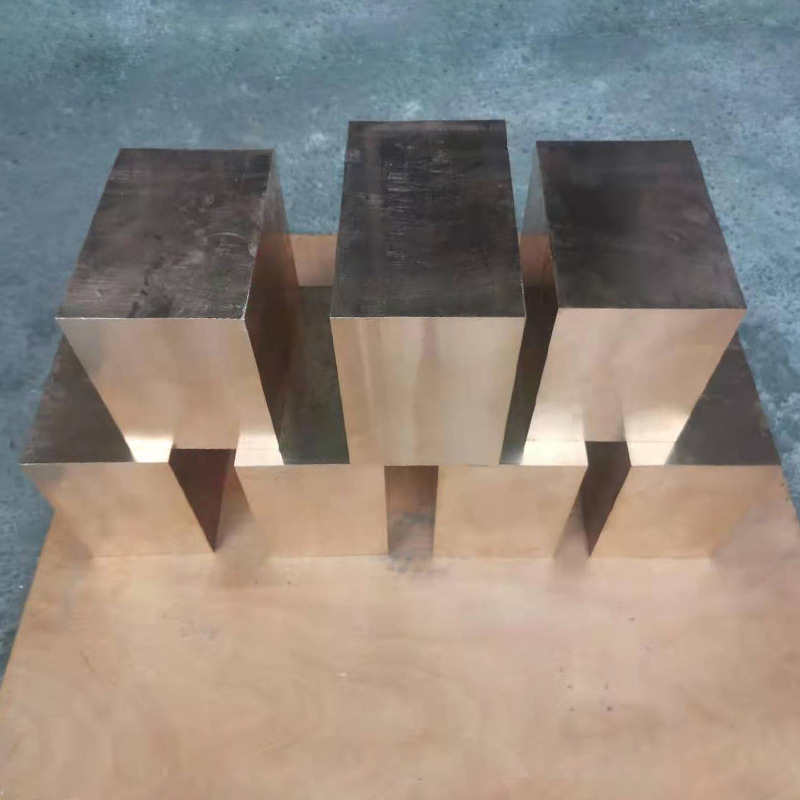

Beryllium copper alloy integrates excellent mechanical properties, physical properties and chemical properties. After heat treatment (solution treatment and aging treatment), it has high strength limit, elastic limit, yield limit and fatigue limit equivalent to that of special steel. It also has high electrical conductivity, thermal conductivity, high hardness, corrosion resistance, wear resistance, good casting performance, non-magnetic and impact and non-spark characteristics, and is widely used in mold manufacturing, machinery, electronics and other industries. No blisters, pores, balanced hardness, dense structure, high strength, good thermal conductivity, good electrical conductivity, corrosion resistance, excellent wear resistance, good processing performance, stable performance under high pressure conditions, non-magnetic, Excellent polishing performance, good anti-adhesion performance.

Applications

Injection molds and high pressure blow molds, mold inserts, rapid cooling, aluminum alloy mold inserts, increase strength, wear resistance and shorten the injection cycle, hot runner nozzles, electrodes and punch materials, not affected by magnetic molds, non-magnetic tools , High thermal conductivity bearings can make mirrors with high surface accuracy. Commonly used beryllium copper grades are as follows: C17200 / C17300 / C17000 are high-strength deformed alloys

C17500 / C17510 are highly conductive deformable alloys;

BeA-275C / BeA-20C is a high-strength casting alloy;

BeA-10C / BeA-50C is a highly conductive casting alloy.

Chemcial Composition

Grade | Be | Co | Ni | Cu | Si | Fe | Al |

C17000 | 0.55-0.75 | 0.35-0.65 | Bal. | 0.2-0.35 | |||

C17200 | 1.9-2.15 | 2.35-2.7 | 0.20-0.25 | Bal. | <0.15 | <0.15 | <0.15 |

C17500 | 0.4-0.7 | 2.4-2.7 | 0.01-0.15 | Bal. | ≤0.2 | ≤0.1 | ≤0.2 |

Mechanical Property

Grade | Strength of extension (MPA) | Yield Strength (0.2% MPA) | Elongation (106psi) | Hardness (HRC) | Conductivity (IACS%) | Density (g/cm3) | Heat conductivity (W/m.k20℃) |

C17000 | 1105 | 1035 | 19 | 36-42 | 18 | 8.3 | 105 |

C17200 | 1070 | 1000 | 19 | 26-32 | 25 | 8.6 | 120 |

C17500 | 1050 | 1000 | 20 | 36-42 | 50 | 8.85 | 235 |

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China