What is inconel wire used for?

Sep

30,2024|

Sep

30,2024| View:660

View:660

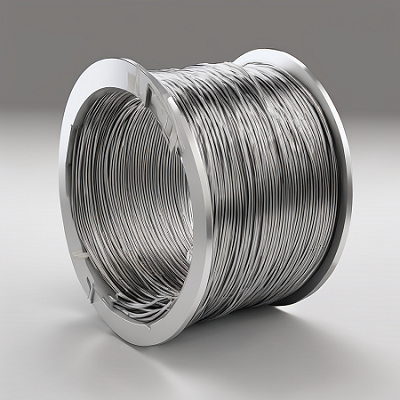

Recently, a material called "Inconel Wire" has attracted widespread attention. So, exactly what is Inconel Wire?

Inconel Wire is a type of nickel-based high-temperature alloy wire. It is mainly composed of nickel, chromium, and various other alloy elements. This special alloy structure endows it with a series of outstanding properties.Inconel Wire has numerous significant advantages. Firstly, it exhibits

extremely excellent high-temperature resistance. In a high-temperature environment, it can still maintain its mechanical strength and stability, which is something many ordinary materials find difficult to achieve. Secondly, its corrosion resistance is also very prominent. Whether facing strong acids, strong alkalis, or other corrosive media, it can effectively resist erosion and ensure long-term stable use. Furthermore, Inconel Wire also has good oxidation resistance, and even when exposed to an oxidizing atmosphere for a long time, it can maintain its original performance. In addition, its high strength and good toughness enable it to adapt to various complex working conditions.

It is precisely because of these advantages that Inconel Wire has a wide range of application scenarios in many fields.

In the aerospace field, Inconel Wire can be said to show its great power. Since aerospace has extremely high requirements for the performance of materials, and Inconel Wire precisely meets these demanding conditions. It is used in the manufacture of key components of aircraft engines, such as blades, turbine disks, etc., to ensure flight safety in high-temperature and high-pressure environments. At the same time, it can also be seen in spacecraft, providing a reliable guarantee for exploring the universe.

The petrochemical industry is also inseparable from Inconel Wire. In the process of oil extraction, the downhole environment is complex and harsh, and the requirements for equipment materials are extremely high. Various components made of Inconel Wire, such as drill pipes, wellhead devices, etc., can operate reliably under extreme conditions, reducing the probability of failure. In chemical production, many reaction processes involve high temperatures and corrosive media, and the corrosion resistance and high-temperature resistance of Inconel Wire play a key role here, ensuring the smooth progress of the production process.

In the energy field, especially in the aspect of nuclear energy, Inconel Wire also has an important position. The environment inside the nuclear reactor is extremely special, and the material needs to have a high degree of stability and radiation resistance. Inconel Wire plays a vital role in the manufacturing of components such as nuclear fuel element casings and control rods, ensuring the safe and efficient use of nuclear energy.

In the automotive industry, Inconel Wire is also beginning to emerge. With the continuous improvement of automotive performance, the requirements for components are also increasing day by day. Inconel Wire can be used to manufacture some key components of high-performance engines to enhance the power and reliability of automobiles.

In addition, in some special industrial applications, such as electronics, medical and other fields, Inconel Wire can also find its use. For example, in medical equipment, its biocompatibility and stability allow it to be used in the manufacture of key components of some high-end medical equipment.

In short, with its unique performance advantages, Inconel Wire plays an indispensable role in various fields. With the continuous progress of technology and the expansion of application fields, it is believed that Inconel Wire will have more extensive and in-depth applications, bringing more convenience and innovation to human production and life. We also look forward to this magical material being able to continuously show more potential and contribute more to the promotion of social development.